<pubnumber> R273194

R273194 </pubnumber>

<title>Identification and Control Of Petrochemical Pollutants Inhibitory To Anaerobic Processes</title>

<pages>125</pages>

<pubyear>1973</pubyear>

<provider>NEPIS</provider>

<access>online</access>

<operator>LAI</operator>

<scandate>20061006</scandate>

<origin>hardcopy</origin>

<type>single page tiff</type>

<keyword>inhibition anaerobic inhibitory acclimation substrate warburg ethyl acrylate crotonaldehyde test activity concentration unit feed gas limited production studies figure packed</keyword>

<author>Hovious, J. C. Waggy, G. T. ; Conway, Richard A. United States. Environmental Protection Agency. Office of Research and Monitoring.</author>

<publisher>For sale by the Supt. of Docs., U.S. Govt. Print. Off.,</publisher>

<subject> Petroleum waste ; Chemical inhibitors ; Sewage--Purification--Biological treatment</subject>

<abstract></abstract>

EPA-R2-73-194

APRIL 1973 Environmental Protection Technology Series

Identification and Control

of Petrochemical Pollutants

Inhibitory to Anaerobic Processes

\

UJ

Office of Research and Monitoring

U.S. Environmental Protection Agency

Washington, D.C. 20460

image:

</pubnumber>

<title>Identification and Control Of Petrochemical Pollutants Inhibitory To Anaerobic Processes</title>

<pages>125</pages>

<pubyear>1973</pubyear>

<provider>NEPIS</provider>

<access>online</access>

<operator>LAI</operator>

<scandate>20061006</scandate>

<origin>hardcopy</origin>

<type>single page tiff</type>

<keyword>inhibition anaerobic inhibitory acclimation substrate warburg ethyl acrylate crotonaldehyde test activity concentration unit feed gas limited production studies figure packed</keyword>

<author>Hovious, J. C. Waggy, G. T. ; Conway, Richard A. United States. Environmental Protection Agency. Office of Research and Monitoring.</author>

<publisher>For sale by the Supt. of Docs., U.S. Govt. Print. Off.,</publisher>

<subject> Petroleum waste ; Chemical inhibitors ; Sewage--Purification--Biological treatment</subject>

<abstract></abstract>

EPA-R2-73-194

APRIL 1973 Environmental Protection Technology Series

Identification and Control

of Petrochemical Pollutants

Inhibitory to Anaerobic Processes

\

UJ

Office of Research and Monitoring

U.S. Environmental Protection Agency

Washington, D.C. 20460

image:

RESEARCH REPORTING SERIES

Research reports of the Office of Research and

Monitoring, Environmental Protection Agency, have

been grouped into five series. These five broad

categories were established to facilitate further

development and application of environmental

technology. Elimination of traditional grouping

was consciously planned to foster technology

transfer and a maximum interface in related

fields. The five series are:

1. Environmental Health Effects Research

2. Environmental Protection Technology

3. Ecological Research

U. Environmental Monitoring

5. Socioeconomic Environmental Studies

This report has been assigned to the ENVIRONMENTAL

PROTECTION TECHNOLOGY series. This series

describes research performed to develop and

demonstrate instrumentation, equipment and

methodology to repair or prevent environmental

degradation from point and non-point sources of

pollution. This work provides the new or improved

technology required for the control and treatment

of pollution sources to meet environmental quality

standards.

image:

RESEARCH REPORTING SERIES

Research reports of the Office of Research and

Monitoring, Environmental Protection Agency, have

been grouped into five series. These five broad

categories were established to facilitate further

development and application of environmental

technology. Elimination of traditional grouping

was consciously planned to foster technology

transfer and a maximum interface in related

fields. The five series are:

1. Environmental Health Effects Research

2. Environmental Protection Technology

3. Ecological Research

U. Environmental Monitoring

5. Socioeconomic Environmental Studies

This report has been assigned to the ENVIRONMENTAL

PROTECTION TECHNOLOGY series. This series

describes research performed to develop and

demonstrate instrumentation, equipment and

methodology to repair or prevent environmental

degradation from point and non-point sources of

pollution. This work provides the new or improved

technology required for the control and treatment

of pollution sources to meet environmental quality

standards.

image:

EPA-R2-73-19A

April 1973

IDENTIFICATION AND CONTROL OF PETROCHEMICAL POLLUTANTS

INHIBITORY TO ANAEROBIC PROCESSES

By

J. C. Hovious

G. T. Waggy

R. A. Conway

Project 12020 FER

Project Officer

Ray George

Environmental Protection Agency

Wheeling Field Office

303 Methodist Building

Wheeling, West Virginia 26003

Prepared for

OFFICE OF RESEARCH AND MONITORING

U.S. ENVIRONMENTAL PROTECTION AGENCY

WASHINGTON, D.C. 20460

1 North !',';.„ , ^. ^,:i /a

Chicago, Illinois 60606

image:

EPA-R2-73-19A

April 1973

IDENTIFICATION AND CONTROL OF PETROCHEMICAL POLLUTANTS

INHIBITORY TO ANAEROBIC PROCESSES

By

J. C. Hovious

G. T. Waggy

R. A. Conway

Project 12020 FER

Project Officer

Ray George

Environmental Protection Agency

Wheeling Field Office

303 Methodist Building

Wheeling, West Virginia 26003

Prepared for

OFFICE OF RESEARCH AND MONITORING

U.S. ENVIRONMENTAL PROTECTION AGENCY

WASHINGTON, D.C. 20460

1 North !',';.„ , ^. ^,:i /a

Chicago, Illinois 60606

image:

EPA Review Notice

This report has been reviewed by the

Environmental Protection Agency and

approved for publication. Approval

does not signify that the contents

necessarily reflect the views and policies

of the Environmental Protection Agency,

nor does mention of trade names or

commercial products constitute endoresement

or recommendations for use.

11

ENVIRONMEN

image:

EPA Review Notice

This report has been reviewed by the

Environmental Protection Agency and

approved for publication. Approval

does not signify that the contents

necessarily reflect the views and policies

of the Environmental Protection Agency,

nor does mention of trade names or

commercial products constitute endoresement

or recommendations for use.

11

ENVIRONMEN

image:

ABSTRACT

Identification studies were made on potentially

inhibitory materials using a Warburg respirometer

procedure and an unacclimated anaerobic biomass.

Identified inhibitory materials and concentrations for a

50 percent decrease in activity were acrolein (20-50 mg/1),

formaldehyde (50-100 mg/1), 2-ethyl-l-hexanol

(500-1000 mg/1), methyl isobutyl ketone (100-300 mg/1),

diethylamine (300-1000 mg/1), acrylonitrile (100 mg/1),

2-methyl-5-ethylpyridine (100 mg/1), ethylene dichloride

(150-500 mg/1), ethyl acrylate (300-600 mg/1), and

phenol (300-LOOO mg/1). Inhibitory effects were more

severe at high volatile acid concentrations.

Acclimation of anaerobic biomass to crotonaldehyde,

phenol, ethyl acrylate, and sodium acrylate was studied

in mixed digesters. An acclimated culture was developed

for crotonaldehyde, phenol, and to some degree to ethyl

acrylate. No acclimation was observed for sodium acrylate.

Cultures acclimated to crotonaldehyde and ethyl acrylate

were able to degrade the material while phenol was not

degraded with acclimation but was no longer inhibitory.

Additional acclimation studies were made in continuously

fed anaerobic filters. A filter was acclimated to a

crotonaldehyde concentration of 600 mg/1 as compared to

the 50-100 mg/1 inhibitory in Warburg studies. Treatment

of formaldehyde, ethyl acrylate, phenol, and acrylonitrile

indicated synergestic inhibitory effects. These mixed

inhibitors were treated satisfactorily at low concentra-

tions in two series anaerobic filters, however, increasing

inhibitor concentrations resulted in failure of both

filters. Actual waste streams treated in an anaerobic

filter indicated that inhibition from crotonaldehyde

could be avoided in a chemical manufacturing waste by

dilution. Successful treatment of "hard" surfactant

containing wastes was also noted. Other means of

overcoming inhibition were discussed.

111

image:

ABSTRACT

Identification studies were made on potentially

inhibitory materials using a Warburg respirometer

procedure and an unacclimated anaerobic biomass.

Identified inhibitory materials and concentrations for a

50 percent decrease in activity were acrolein (20-50 mg/1),

formaldehyde (50-100 mg/1), 2-ethyl-l-hexanol

(500-1000 mg/1), methyl isobutyl ketone (100-300 mg/1),

diethylamine (300-1000 mg/1), acrylonitrile (100 mg/1),

2-methyl-5-ethylpyridine (100 mg/1), ethylene dichloride

(150-500 mg/1), ethyl acrylate (300-600 mg/1), and

phenol (300-LOOO mg/1). Inhibitory effects were more

severe at high volatile acid concentrations.

Acclimation of anaerobic biomass to crotonaldehyde,

phenol, ethyl acrylate, and sodium acrylate was studied

in mixed digesters. An acclimated culture was developed

for crotonaldehyde, phenol, and to some degree to ethyl

acrylate. No acclimation was observed for sodium acrylate.

Cultures acclimated to crotonaldehyde and ethyl acrylate

were able to degrade the material while phenol was not

degraded with acclimation but was no longer inhibitory.

Additional acclimation studies were made in continuously

fed anaerobic filters. A filter was acclimated to a

crotonaldehyde concentration of 600 mg/1 as compared to

the 50-100 mg/1 inhibitory in Warburg studies. Treatment

of formaldehyde, ethyl acrylate, phenol, and acrylonitrile

indicated synergestic inhibitory effects. These mixed

inhibitors were treated satisfactorily at low concentra-

tions in two series anaerobic filters, however, increasing

inhibitor concentrations resulted in failure of both

filters. Actual waste streams treated in an anaerobic

filter indicated that inhibition from crotonaldehyde

could be avoided in a chemical manufacturing waste by

dilution. Successful treatment of "hard" surfactant

containing wastes was also noted. Other means of

overcoming inhibition were discussed.

111

image:

image:

image:

CONTENTS

Section Page

I Conclusions 1

II Recommendations 3

III Introduction 5

IV Identification of Inhibitory 7

Chemicals

V Control of Inhibitory Materials 45

VI Acknowledgements 95

VII References 97

VIII Appendix 99

image:

CONTENTS

Section Page

I Conclusions 1

II Recommendations 3

III Introduction 5

IV Identification of Inhibitory 7

Chemicals

V Control of Inhibitory Materials 45

VI Acknowledgements 95

VII References 97

VIII Appendix 99

image:

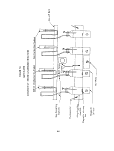

FIGURES

No. Page

1 Effect of Various Compounds on 9

Anaerobic Activity of

Domestic Sludge

2 Fed-Warburg Data Collection and 16

Handling

3 Typical Warburg Respirometer Test 17

Data

4 Effect of Acrolein on Anaerobic 26

Activity

5 Effect of Crotonaldehyde on 27

Anaerobic Activity

6 Effect of Formaldehyde on Anaerobic 28

Activity

7 Effect of Methyl Isobutyl Ketone 29

on Anaerobic Activity

8 Effect of Ethylenediamine on 30

Anaerobic Activity

9 Effect of Diethylamine on Anaerobic 31

Activity

10 Effect of Acrylonitrile on Anaerobic 32

Activity

11 Effect of 2-Methyl-5-Ethylpyridine 33

on Anaerobic Activity

12 Effect of Phenol on Anaerobic Activity 34

13 Effect of Sodium Acrylate on 35

Anaerobic Activity

14 Effect of Ethyl Acrylate on Anaerobic 36

Activity

15 Effect of 2-Ethyl-l-hexanol on 37

Anaerobic Activity

vi

image:

FIGURES

No. Page

1 Effect of Various Compounds on 9

Anaerobic Activity of

Domestic Sludge

2 Fed-Warburg Data Collection and 16

Handling

3 Typical Warburg Respirometer Test 17

Data

4 Effect of Acrolein on Anaerobic 26

Activity

5 Effect of Crotonaldehyde on 27

Anaerobic Activity

6 Effect of Formaldehyde on Anaerobic 28

Activity

7 Effect of Methyl Isobutyl Ketone 29

on Anaerobic Activity

8 Effect of Ethylenediamine on 30

Anaerobic Activity

9 Effect of Diethylamine on Anaerobic 31

Activity

10 Effect of Acrylonitrile on Anaerobic 32

Activity

11 Effect of 2-Methyl-5-Ethylpyridine 33

on Anaerobic Activity

12 Effect of Phenol on Anaerobic Activity 34

13 Effect of Sodium Acrylate on 35

Anaerobic Activity

14 Effect of Ethyl Acrylate on Anaerobic 36

Activity

15 Effect of 2-Ethyl-l-hexanol on 37

Anaerobic Activity

vi

image:

No. Page

16 Effect of Ethylene Bichloride on 38

Anaerobic Activity

17 Batch-Fed Anaerobic Reactors 47

18 Batch-Fed Completely Mixed Anaerobic 48

Reactors

19 Acclimation Studies with Crotonaldehyde 50

20 Acclimation Studies with Ethyl Acrylate 51

21 Acclimation Studies with Methyl Ethyl 52

Pyridine

22 Gas Production in Acclimation Unit 55

Receiving Crotonaldehyde

23 Gas Production in Acclimation Unit 56

Receiving Phenol

24 Gas Production in Acclimation Unit 57

Receiving Ethyl Acrylate

25 Gas Production in Acclimation Unit 58

Receiving Sodium Acrylate

26 Warburg Test of Acclimation to 59

Crotonaldehyde

27 Warburg Test of Acclimation to Phenol 61

28 Warburg Test of Acclimation to Ethyl 62

Acrylate

29 Warburg Test of Acclimation to Sodium 63

Acrylate

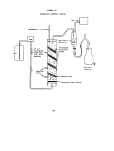

30 Packed-Bed Anaerobic Reactor 66

31 Dye Study on Packed-Bed Reactor 68

32 Effect of Crotonaldehyde on Performance 71

of Packed-Bed Anaerobic Treatment

Unit

vii

image:

No. Page

16 Effect of Ethylene Bichloride on 38

Anaerobic Activity

17 Batch-Fed Anaerobic Reactors 47

18 Batch-Fed Completely Mixed Anaerobic 48

Reactors

19 Acclimation Studies with Crotonaldehyde 50

20 Acclimation Studies with Ethyl Acrylate 51

21 Acclimation Studies with Methyl Ethyl 52

Pyridine

22 Gas Production in Acclimation Unit 55

Receiving Crotonaldehyde

23 Gas Production in Acclimation Unit 56

Receiving Phenol

24 Gas Production in Acclimation Unit 57

Receiving Ethyl Acrylate

25 Gas Production in Acclimation Unit 58

Receiving Sodium Acrylate

26 Warburg Test of Acclimation to 59

Crotonaldehyde

27 Warburg Test of Acclimation to Phenol 61

28 Warburg Test of Acclimation to Ethyl 62

Acrylate

29 Warburg Test of Acclimation to Sodium 63

Acrylate

30 Packed-Bed Anaerobic Reactor 66

31 Dye Study on Packed-Bed Reactor 68

32 Effect of Crotonaldehyde on Performance 71

of Packed-Bed Anaerobic Treatment

Unit

vii

image:

No. Page

33 Effect of Four Inhibitors on Performance 73

of Packed-Bed Anaerobic Treatment Unit

34 Performance of Anaerobic Packed Column 80

Treating Inhibitory Wastewater

35 Peformance of Anaerobic Packed Column 84

Treating Surfactant Containing

Wastewater

36 Anaerobic Lagoon 87

37 Lagoon Sulfate-Sulfide Concentrations 93

Vlll

image:

No. Page

33 Effect of Four Inhibitors on Performance 73

of Packed-Bed Anaerobic Treatment Unit

34 Performance of Anaerobic Packed Column 80

Treating Inhibitory Wastewater

35 Peformance of Anaerobic Packed Column 84

Treating Surfactant Containing

Wastewater

36 Anaerobic Lagoon 87

37 Lagoon Sulfate-Sulfide Concentrations 93

Vlll

image:

TABLES

No. Page

1 Effect of Various Compounds Toward 11

Anaerobic Biological Treatment

2 Computation of Rate of Substrate 13

Removal at Various Substrate

Concentrations

3 Rate of Gas Production at Various 14

Supplemental Acetate Levels

4 Chemical Structures Evaluated in 19

Warburg Inhibition Studies

5 Individual Warburg Inhibition Data 22

for Non-Substrate-Limiting

Conditions

6 Summary of Effects of Tested Materials 23

on Anaerobic Activity

7 Identified Problem Concentrations of 42

Tested Materials

8 Supporting Analytical Data on Batch-Fed 53

Acclimation Reactors

9 Warburg Respirometer Evaluation of 64

Acclimation Achieved for

Crotonaldehyde, Phenol, Sodium

Acrylate, and Ethyl Acrylate in

Continuously Mixed Reactors

10 Volatile Acid and Specific Organic 69

Profiles in Operating Columns

11 Performance of Two-Stage Filter 74

Treating Combined Inhibitory

Chemicals

12 Chromatographic Examination of Series 76

Packed Columns Treating Mixed

Inhibitors

IX

image:

TABLES

No. Page

1 Effect of Various Compounds Toward 11

Anaerobic Biological Treatment

2 Computation of Rate of Substrate 13

Removal at Various Substrate

Concentrations

3 Rate of Gas Production at Various 14

Supplemental Acetate Levels

4 Chemical Structures Evaluated in 19

Warburg Inhibition Studies

5 Individual Warburg Inhibition Data 22

for Non-Substrate-Limiting

Conditions

6 Summary of Effects of Tested Materials 23

on Anaerobic Activity

7 Identified Problem Concentrations of 42

Tested Materials

8 Supporting Analytical Data on Batch-Fed 53

Acclimation Reactors

9 Warburg Respirometer Evaluation of 64

Acclimation Achieved for

Crotonaldehyde, Phenol, Sodium

Acrylate, and Ethyl Acrylate in

Continuously Mixed Reactors

10 Volatile Acid and Specific Organic 69

Profiles in Operating Columns

11 Performance of Two-Stage Filter 74

Treating Combined Inhibitory

Chemicals

12 Chromatographic Examination of Series 76

Packed Columns Treating Mixed

Inhibitors

IX

image:

No. Page

13 Waste Streams Studied in Anaerobic 78

Packed Columns

14 Data on Packed-Bed Anaerobic Reactor 81

Treating Inhibitory Wastewater

15 Data on Packed-Bed Anaerobic Reactor 83

Treating Surfactant Containing

Wastewater

16 Anaerobic Lagoon Feed 88

17 Photosynthetic Bacterial Growth on 90

Pure Chemical Substrates

18 Sulfur Lagoon Data 91

x

image:

No. Page

13 Waste Streams Studied in Anaerobic 78

Packed Columns

14 Data on Packed-Bed Anaerobic Reactor 81

Treating Inhibitory Wastewater

15 Data on Packed-Bed Anaerobic Reactor 83

Treating Surfactant Containing

Wastewater

16 Anaerobic Lagoon Feed 88

17 Photosynthetic Bacterial Growth on 90

Pure Chemical Substrates

18 Sulfur Lagoon Data 91

x

image:

SECTION I

CONCLUSIONS

1. A rapid, reproducible procedure using a Warburg

respirometer was developed to assess and quantify the

inhibitory effect of materials on unacclimated anaerobic

microorganisms which metabolize acetate. This procedure

provides lower threshold limits of material concentration

for inhibition. Greater concentrations could possibly be

tolerated by acclimated anaerobic organisms.

2. The <y<-fi unsaturated aldehydes were particularly

inhibitory to unacclimated anaerobic systems at low

concentrations of 20-100 mg/1. Other materials which

could result in inhibition problems were found to be

2-ethyl-l-hexanol, methyl isobutyl ketone, diethylamine,

ethylenediamine, acrylonitrile, 2-methyl-5-ethylpyridine,

phenol, ethylene dichloride, and ethyl acrylate.

3. Inhibition of gas production was found to be more

severe in a system containing volatile acid concentrations

greater than 500 mg/1 as acetic. Inhibition also occurred

at lower concentrations of test material under these

conditions.

4. Introduction of test material at a gradually increasing

level to continuously mixed batch-fed digesters resulted in

acclimation and increased resistance to inhibition by

crotonaldehyde, ethyl acrylate and phenol. Crotonaldehyde

and ethyl acrylate were degraded completely in the

acclimation digesters, while phenol was not. Similar

acclimation experiments with sodium acrylate indicated

no significant increase in resistance to inhibition.

5. Acclimation of anaerobic microorganisms in mixed

digester cultures was found to be at best a difficult

and long-term procedure with only moderate chances of

success.

6. A continuously fed anaerobic, packed-bed filter was

able to treat successfully a stream containing 600 mg/1

crotonaldehyde at a 1.5 day detention time. Crotonaldehyde

had been proved inhibitory to unacclimated microorganisms

at 50 to 100 mg/1. The column failed at about a concen-

tration range of 700 to 800 mg/1.

image:

SECTION I

CONCLUSIONS

1. A rapid, reproducible procedure using a Warburg

respirometer was developed to assess and quantify the

inhibitory effect of materials on unacclimated anaerobic

microorganisms which metabolize acetate. This procedure

provides lower threshold limits of material concentration

for inhibition. Greater concentrations could possibly be

tolerated by acclimated anaerobic organisms.

2. The <y<-fi unsaturated aldehydes were particularly

inhibitory to unacclimated anaerobic systems at low

concentrations of 20-100 mg/1. Other materials which

could result in inhibition problems were found to be

2-ethyl-l-hexanol, methyl isobutyl ketone, diethylamine,

ethylenediamine, acrylonitrile, 2-methyl-5-ethylpyridine,

phenol, ethylene dichloride, and ethyl acrylate.

3. Inhibition of gas production was found to be more

severe in a system containing volatile acid concentrations

greater than 500 mg/1 as acetic. Inhibition also occurred

at lower concentrations of test material under these

conditions.

4. Introduction of test material at a gradually increasing

level to continuously mixed batch-fed digesters resulted in

acclimation and increased resistance to inhibition by

crotonaldehyde, ethyl acrylate and phenol. Crotonaldehyde

and ethyl acrylate were degraded completely in the

acclimation digesters, while phenol was not. Similar

acclimation experiments with sodium acrylate indicated

no significant increase in resistance to inhibition.

5. Acclimation of anaerobic microorganisms in mixed

digester cultures was found to be at best a difficult

and long-term procedure with only moderate chances of

success.

6. A continuously fed anaerobic, packed-bed filter was

able to treat successfully a stream containing 600 mg/1

crotonaldehyde at a 1.5 day detention time. Crotonaldehyde

had been proved inhibitory to unacclimated microorganisms

at 50 to 100 mg/1. The column failed at about a concen-

tration range of 700 to 800 mg/1.

image:

7. Treatment of four combined inhibitors in an

anaerobic filter indicated a synergistic

effect regarding the threshold limits for anaerobic

inhibition.

8. Two series anaerobic filters were acceptable for

treatment of the combined inhibitors at low concentra-

tions. The initial column provided no oxygen-demand

removal but modified the stream for treatment in a

subsequent column. Increasing inhibitor concentrations

resulted in complete inhibition of both columns.

9. Waste from a chemical production unit, containing

a high concentration of crotonaldehyde, was biologically

degraded in an anaerobic filter by a microbial culture

acclimated by initial dilution and stepwise increases in

waste concentration. A COD removal of 68 percent was

observed.

10. A surfactant-containing petrochemical waste treated

in an anaerobic filter exhibited complete removal of a

"hard" nonionic surfactant at a concentration of

45 mg/1 after acclimation. Higher concentrations resulted

in leakage through the system.

11. An experimental system designed to quantify photo-

synthetic sulfide oxidation by bacteria of the family

Thiorhodaceae was never able to maintain a significant

population of these bacteria. The Chlorobacteriaceae

which predominated did not provide significant sulfide

oxidation.

image:

7. Treatment of four combined inhibitors in an

anaerobic filter indicated a synergistic

effect regarding the threshold limits for anaerobic

inhibition.

8. Two series anaerobic filters were acceptable for

treatment of the combined inhibitors at low concentra-

tions. The initial column provided no oxygen-demand

removal but modified the stream for treatment in a

subsequent column. Increasing inhibitor concentrations

resulted in complete inhibition of both columns.

9. Waste from a chemical production unit, containing

a high concentration of crotonaldehyde, was biologically

degraded in an anaerobic filter by a microbial culture

acclimated by initial dilution and stepwise increases in

waste concentration. A COD removal of 68 percent was

observed.

10. A surfactant-containing petrochemical waste treated

in an anaerobic filter exhibited complete removal of a

"hard" nonionic surfactant at a concentration of

45 mg/1 after acclimation. Higher concentrations resulted

in leakage through the system.

11. An experimental system designed to quantify photo-

synthetic sulfide oxidation by bacteria of the family

Thiorhodaceae was never able to maintain a significant

population of these bacteria. The Chlorobacteriaceae

which predominated did not provide significant sulfide

oxidation.

image:

SECTION II

RECOMMENDATIONS

It is recommended that:

1. Long-term continuously-fed reaction studies tailored

to the expected treatment conditions be conducted for

wastes having a mixture of anaerobic inhibitors or a

system which will receive a continuous inhibitor dosage

due to

a) The synergestic effects of mixed inhibitors.

b) The variation of inhibitory effect with

system volatile acid levels.

c) Bioacclimation which can be achieved with

certain potentially inhibitory chemicals.

2. That the "activity ratio" procedure be utilized to

determine approximate concentration limits for single

material inhibition of unacclimated anaerobic systems.

Such ratios would reflect the effects of "slug" doses

on anaerobic systems.

3. That further study of photosynthetic, sulfur-

oxidizing bacteria be conducted including the environ-

mental conditions for optimal growth and the effects

of petrochemical waste constituents on metabolism.

Field studies are recommended since a significant

population of these bacteria could not be maintained

during laboratory studies conducted as part of this

project.

4. Experimental results obtained by using acclimated

sludge on a limited basis warrants further work in this

area. It would be expected that highest activity

ratios would be obtained by using an acclimated biota.

image:

SECTION II

RECOMMENDATIONS

It is recommended that:

1. Long-term continuously-fed reaction studies tailored

to the expected treatment conditions be conducted for

wastes having a mixture of anaerobic inhibitors or a

system which will receive a continuous inhibitor dosage

due to

a) The synergestic effects of mixed inhibitors.

b) The variation of inhibitory effect with

system volatile acid levels.

c) Bioacclimation which can be achieved with

certain potentially inhibitory chemicals.

2. That the "activity ratio" procedure be utilized to

determine approximate concentration limits for single

material inhibition of unacclimated anaerobic systems.

Such ratios would reflect the effects of "slug" doses

on anaerobic systems.

3. That further study of photosynthetic, sulfur-

oxidizing bacteria be conducted including the environ-

mental conditions for optimal growth and the effects

of petrochemical waste constituents on metabolism.

Field studies are recommended since a significant

population of these bacteria could not be maintained

during laboratory studies conducted as part of this

project.

4. Experimental results obtained by using acclimated

sludge on a limited basis warrants further work in this

area. It would be expected that highest activity

ratios would be obtained by using an acclimated biota.

image:

image:

image:

SECTION III

INTRODUCTION

Treatment of aqueous wastes from petrochemical manufac-

turing facilities has been found to be complicated com-

ponents inhibitory to biological treatment systems at

relatively low concentrations (1, 2). During an EPA

funded anaerobic process development grant (12020-DIS),

the use of high rate anaerobic systems was precluded

due to inhibition problems. While considerable

experimental effort has been spent on the behavior of

specific synthetic organic materials in aerobic

systems (3-8), virtually no work has been published on

inhibition in anaerobic systems with the exceptions of

volatile acids and inorganic materials (9). With the

development of anaerobic processes specifically for

petrochemical wastes (1, 2, 10), the need for inhibition

data on specific materials is apparent. Such data are

also needed for operation of anaerobic digesters receiving

sludges from aerobic systems treating petrochemical

wastes.

Inhibition of a microbiological process may result from

a general effect on the environment of the process as a

whole, or effects on the specific cells or enzymes

within the process. As an example, addition of a strong

acid in excess of system buffering capacity would result

in inhibition due to low system pH while a mercury salt

will combine with the enzymes containing sulfur in thiol

groups (-SH) thus inhibiting activity. As the general

environmental limits for anaerobic treatment are well

defined and every attempt is made to control these in a

treatment process, this study was centered on the effects

of materials which would act on cellular constituents or

enzyme systems.

Inhibition of a chemical on a cellular constituent may

be the result of a reaction with some essential group of a

protein or other molecule or adsorption at the cell

surface. Such a reaction may result in conversion

of a metabolically active substance to an inactive

substance or a change in cell permeability. An example

of reaction with an essential group of a protein would

be the mercury-thiol bonding while surface active

materials such as phenols are inhibitory due to inter-

ference with cellular permeability.

image:

SECTION III

INTRODUCTION

Treatment of aqueous wastes from petrochemical manufac-

turing facilities has been found to be complicated com-

ponents inhibitory to biological treatment systems at

relatively low concentrations (1, 2). During an EPA

funded anaerobic process development grant (12020-DIS),

the use of high rate anaerobic systems was precluded

due to inhibition problems. While considerable

experimental effort has been spent on the behavior of

specific synthetic organic materials in aerobic

systems (3-8), virtually no work has been published on

inhibition in anaerobic systems with the exceptions of

volatile acids and inorganic materials (9). With the

development of anaerobic processes specifically for

petrochemical wastes (1, 2, 10), the need for inhibition

data on specific materials is apparent. Such data are

also needed for operation of anaerobic digesters receiving

sludges from aerobic systems treating petrochemical

wastes.

Inhibition of a microbiological process may result from

a general effect on the environment of the process as a

whole, or effects on the specific cells or enzymes

within the process. As an example, addition of a strong

acid in excess of system buffering capacity would result

in inhibition due to low system pH while a mercury salt

will combine with the enzymes containing sulfur in thiol

groups (-SH) thus inhibiting activity. As the general

environmental limits for anaerobic treatment are well

defined and every attempt is made to control these in a

treatment process, this study was centered on the effects

of materials which would act on cellular constituents or

enzyme systems.

Inhibition of a chemical on a cellular constituent may

be the result of a reaction with some essential group of a

protein or other molecule or adsorption at the cell

surface. Such a reaction may result in conversion

of a metabolically active substance to an inactive

substance or a change in cell permeability. An example

of reaction with an essential group of a protein would

be the mercury-thiol bonding while surface active

materials such as phenols are inhibitory due to inter-

ference with cellular permeability.

image:

Enzyme inhibition results from competition between the

inhibitor and substrate for attachment sites on the

enzyme, an attraction of the inhibitor for a part of

the enzyme, or destruction of an essential functional

group of the enzyme. The relative effect of any inhibitory

material on a microbial process may be expected to depend

on the properties of the microbial growth. As an

example, rapidly growing cells would be expected

to be more susceptible to inhibitory materials than

slower growing cells since a higher uptake and conversion

of substrate is in progress. Also, microorganisms which

grow in clusters or have slime layers would be expected

to be less sensitive than dispersed organisms as less

opportunity is available for inhibitor-organism contact.

Application of various inhibition theories to an

anaerobic treatment process is complicated by the mixed

biological cultures necessary within the process and the

mixture commonly present in the waste. While a material

may be inhibitory to one type of organism within a

treatment system, there may well be others present

which can degrade the material and thus overcome the

inhibitory effects. Mixed chemicals could also have

synergistic or antagonistic effects on the culture.

In order to develop a widely usable set of data, initial

screening studies for inhibition were performed with a

single material and an unacclimated, mixed anaerobic

culture. Many materials which were found to be

inhibitory in short-term screening studies were then

subjected to acclimation procedures, either as the

single compound or in a real waste stream to measure

long-term effects in more realistic situations.

Materials of particular interest were alpha-beta

unsaturated carbonyl compounds, since these have been

previously identified as inhibitory in aerobic system (5).

Once the inhibitory materials and related problem

concentrations are known, procedures may be developed

for control of the inhibitory effects. A classic

example would be the control of heavy metal toxicity

in digesters by the addition of sulfates which are

reduced bacterially to sulfides, resulting in a non-

toxic, heavy metal-sulfide precipitate.

image:

Enzyme inhibition results from competition between the

inhibitor and substrate for attachment sites on the

enzyme, an attraction of the inhibitor for a part of

the enzyme, or destruction of an essential functional

group of the enzyme. The relative effect of any inhibitory

material on a microbial process may be expected to depend

on the properties of the microbial growth. As an

example, rapidly growing cells would be expected

to be more susceptible to inhibitory materials than

slower growing cells since a higher uptake and conversion

of substrate is in progress. Also, microorganisms which

grow in clusters or have slime layers would be expected

to be less sensitive than dispersed organisms as less

opportunity is available for inhibitor-organism contact.

Application of various inhibition theories to an

anaerobic treatment process is complicated by the mixed

biological cultures necessary within the process and the

mixture commonly present in the waste. While a material

may be inhibitory to one type of organism within a

treatment system, there may well be others present

which can degrade the material and thus overcome the

inhibitory effects. Mixed chemicals could also have

synergistic or antagonistic effects on the culture.

In order to develop a widely usable set of data, initial

screening studies for inhibition were performed with a

single material and an unacclimated, mixed anaerobic

culture. Many materials which were found to be

inhibitory in short-term screening studies were then

subjected to acclimation procedures, either as the

single compound or in a real waste stream to measure

long-term effects in more realistic situations.

Materials of particular interest were alpha-beta

unsaturated carbonyl compounds, since these have been

previously identified as inhibitory in aerobic system (5).

Once the inhibitory materials and related problem

concentrations are known, procedures may be developed

for control of the inhibitory effects. A classic

example would be the control of heavy metal toxicity

in digesters by the addition of sulfates which are

reduced bacterially to sulfides, resulting in a non-

toxic, heavy metal-sulfide precipitate.

image:

SECTION IV

IDENTIFICATION OF INHIBITORY CHEMICALS

Initial Screening Tests

In order to screen the effects of a number of materials

on anaerobic processes, a method was needed which would

provide direct, reproducible inhibition data with a

minimum effort for each material tested.

Metabolic parameters such as cell growth, organic

reduction, and gas uptake or production in anaerobic

systems are normally utilized to monitor microorganism

activity. The required methanogenic phase of a non-

photosynthetic anaerobic process is generally conceded

to be both the most sensitive and the rate-limiting

step in anaerobic treatment, excluding systems based

on nitrate or sulfate reduction. Careful measurement

of gas produced in test units was, therefore, selected

as the indicator of bacterial activity. Cell growth

and organic reduction measurements were not considered

suitable for the type of short-term, small-volume tests

envisioned for this phase of the study.

The Warburg constant-volume respirometer was selected for

use in screening tests due to its high sensitivity to

gas pressure changes and the potential for rapid collection

of data. Anaerobic Warburg procedures in the

literature (11, 12), emphasize the importance of

developing carefully controlled operating techniques.

The necessity of an oxygen-free atmosphere over the

anaerobic biomass during the system charging and

throughout the test period presents operational

problems which needed to be solved prior to conducting

quantitative Warburg studies with the test chemicals.

Procedure

In initial qualitative tests, a Warburg respirometer

fitted with 18 flasks and manometers was used to

measure the effect of individual chemicals on the

methanogenic bacteria by monitoring gas production.

The flasks (140-ml volume) were charged initially with

sufficient nitrogen-sparged distilled water so that

when dilution water plus nutrients, domestic anaerobic

sludge, and test chemicals were added, a final volume

image:

SECTION IV

IDENTIFICATION OF INHIBITORY CHEMICALS

Initial Screening Tests

In order to screen the effects of a number of materials

on anaerobic processes, a method was needed which would

provide direct, reproducible inhibition data with a

minimum effort for each material tested.

Metabolic parameters such as cell growth, organic

reduction, and gas uptake or production in anaerobic

systems are normally utilized to monitor microorganism

activity. The required methanogenic phase of a non-

photosynthetic anaerobic process is generally conceded

to be both the most sensitive and the rate-limiting

step in anaerobic treatment, excluding systems based

on nitrate or sulfate reduction. Careful measurement

of gas produced in test units was, therefore, selected

as the indicator of bacterial activity. Cell growth

and organic reduction measurements were not considered

suitable for the type of short-term, small-volume tests

envisioned for this phase of the study.

The Warburg constant-volume respirometer was selected for

use in screening tests due to its high sensitivity to

gas pressure changes and the potential for rapid collection

of data. Anaerobic Warburg procedures in the

literature (11, 12), emphasize the importance of

developing carefully controlled operating techniques.

The necessity of an oxygen-free atmosphere over the

anaerobic biomass during the system charging and

throughout the test period presents operational

problems which needed to be solved prior to conducting

quantitative Warburg studies with the test chemicals.

Procedure

In initial qualitative tests, a Warburg respirometer

fitted with 18 flasks and manometers was used to

measure the effect of individual chemicals on the

methanogenic bacteria by monitoring gas production.

The flasks (140-ml volume) were charged initially with

sufficient nitrogen-sparged distilled water so that

when dilution water plus nutrients, domestic anaerobic

sludge, and test chemicals were added, a final volume

image:

of 50 milliliters would result. The test chemical was

added to give the desired final concentration (usually

150, 500 or 1000 mg/1). Aliquots of one-percent

solutions of the water-soluble test chemicals were

used, while insoluble chemicals were added via a micro-

syringe technique. Twenty milliliters of nitrogen-

sparged dilution water, containing one milliliter of

buffer-nutrient solution per liter were then added,

followed by 25 milliliters of undiluted anaerobic sludge

conditioned at 35°C. All transfers were made under a

nitrogen-gas blanket.

The flasks were then attached to the manometer and

placed in the 35°C bath. The side arm of the flask was

opened, and nitrogen was purged through the flask for

30 minutes. The nitrogen was turned off, the side arms

closed and the shaker mechanism started. Gas pressure

changes were very rapid during the first few minutes

as equilibrium was reached between the dissolved gases

in the sludge and the nitrogen atmosphere. After

shaking 15 minutes, the manometers were leveled, and

gas pressure was measured at desired intervals.

Pressure readings were corrected for changes in

atmospheric pressure and temperature by using a

thermobarometer flask containing only distilled water.

Corrected gas pressure values were plotted against

time for a period of 300 minutes to show the relative

rate of gas production during this period.

Gas production of the control flask (seed biomass) would

represent the cumulative production from methane

fermentation, anaerobic respiration, and fermentation

of carbohydrates and other materials in the domestic

waste solids used as seed. Addition of a test chemical

could affect the gas production in one of three ways -

increased production, no change, or decreased production.

An increased production would indicate that the test

material was degradable by the anaerobic sludge, although

not necessarily through methane fermentation. No

change in gas production from the control indicates no

net inhibition and/or degradation, while a decrease in

gas production shows inhibition. The effect of some

selected chemicals on the activity of domestic

anaerobic sludge is shown in Figure 1.

8

image:

of 50 milliliters would result. The test chemical was

added to give the desired final concentration (usually

150, 500 or 1000 mg/1). Aliquots of one-percent

solutions of the water-soluble test chemicals were

used, while insoluble chemicals were added via a micro-

syringe technique. Twenty milliliters of nitrogen-

sparged dilution water, containing one milliliter of

buffer-nutrient solution per liter were then added,

followed by 25 milliliters of undiluted anaerobic sludge

conditioned at 35°C. All transfers were made under a

nitrogen-gas blanket.

The flasks were then attached to the manometer and

placed in the 35°C bath. The side arm of the flask was

opened, and nitrogen was purged through the flask for

30 minutes. The nitrogen was turned off, the side arms

closed and the shaker mechanism started. Gas pressure

changes were very rapid during the first few minutes

as equilibrium was reached between the dissolved gases

in the sludge and the nitrogen atmosphere. After

shaking 15 minutes, the manometers were leveled, and

gas pressure was measured at desired intervals.

Pressure readings were corrected for changes in

atmospheric pressure and temperature by using a

thermobarometer flask containing only distilled water.

Corrected gas pressure values were plotted against

time for a period of 300 minutes to show the relative

rate of gas production during this period.

Gas production of the control flask (seed biomass) would

represent the cumulative production from methane

fermentation, anaerobic respiration, and fermentation

of carbohydrates and other materials in the domestic

waste solids used as seed. Addition of a test chemical

could affect the gas production in one of three ways -

increased production, no change, or decreased production.

An increased production would indicate that the test

material was degradable by the anaerobic sludge, although

not necessarily through methane fermentation. No

change in gas production from the control indicates no

net inhibition and/or degradation, while a decrease in

gas production shows inhibition. The effect of some

selected chemicals on the activity of domestic

anaerobic sludge is shown in Figure 1.

8

image:

<0 DC

&

M

>

§

-1 §

w

g 8

5 g

fe O W

a <§

w

3

8

CO

§

l-l

OS

H

3

a

•H

c

o

•H

•M

CO

h

Q

C

3

O

O

o

o

o

o

m

IN

mm 'aanssajd SBQ

image:

<0 DC

&

M

>

§

-1 §

w

g 8

5 g

fe O W

a <§

w

3

8

CO

§

l-l

OS

H

3

a

•H

c

o

•H

•M

CO

h

Q

C

3

O

O

o

o

o

o

m

IN

mm 'aanssajd SBQ

image:

The activity of the test sludge system relative to that

of the unfed sludge control was computed by dividing

the millimeters of gas pressure built up by the sample

by the millimeters of gas pressure built up by the

control after 300 minutes. These data are summarized

in Table 1.

10

image:

The activity of the test sludge system relative to that

of the unfed sludge control was computed by dividing

the millimeters of gas pressure built up by the sample

by the millimeters of gas pressure built up by the

control after 300 minutes. These data are summarized

in Table 1.

10

image:

TABLE 1

EFFECT OF VARIOUS COMPOUNDS TOWARD ANAEROBIC

ACTIVITY UNDER SUBSTRATE LIMITING CONDITIONS

(3)

Compound

t-Butanol

2-Ethyl-l-hexanol

Crotonaldehyde(^)

Crotonaldehyde(4)

Methyl isobutyl ketone

Isophorone

Aerylonitrile

2-Methyl-5-ethyl pyridine

N,N-DimethyIaniline

Phenol

C3)

Ethyl benzene

Ethylene dichloride

Ethyl acrylate

Dodecane(3)

Dextrose

Ethyl acetate

Ethylene glycol

Tetralin(3)

Sodium acetate

Mercuric chloride

(3)

,(3)

Relative Activity with

Respect to Control at

Four Concentrations (mg/1)

(2)

150 200

0.91

1.15

0.23

0.54

1 .05

1.13

0.63

1.20

1.07

1.06

0.96

0.84

1.04

1.04

1.98

1 .40

1.46

1.23

1.88

_ _

500

0.96

0.71

-

-

1.05

1.12

0.43

-

-

1.15

0.96

0.43

0.61

1.10

-

1.77

1.65

1.29

2.02

0.27

1000

0.89

0.42

0.23

0.49

1.03

0.81

0.35

0.65

1.37

1.02

1.10

0.43

0.39

1.27

2.30

2.19

1.70

1.24

1.30

_

(1)

Initial studies performed under EPA Grant 12020-DIS,

"Anaerobic Treatment of Synthetic Organic wastes".

(2)

The mm of gas pressure of a sample divided by mm gas

pressure of control after 300 min; a value less than 1,

indicates inhibition while a value greater than 1.00

indicates degradation.

(3)

(4)

00

Compounds added with a micro-syringe because of solubility

Variable effect dependent upon system volatile acid

concentration.

11

image:

TABLE 1

EFFECT OF VARIOUS COMPOUNDS TOWARD ANAEROBIC

ACTIVITY UNDER SUBSTRATE LIMITING CONDITIONS

(3)

Compound

t-Butanol

2-Ethyl-l-hexanol

Crotonaldehyde(^)

Crotonaldehyde(4)

Methyl isobutyl ketone

Isophorone

Aerylonitrile

2-Methyl-5-ethyl pyridine

N,N-DimethyIaniline

Phenol

C3)

Ethyl benzene

Ethylene dichloride

Ethyl acrylate

Dodecane(3)

Dextrose

Ethyl acetate

Ethylene glycol

Tetralin(3)

Sodium acetate

Mercuric chloride

(3)

,(3)

Relative Activity with

Respect to Control at

Four Concentrations (mg/1)

(2)

150 200

0.91

1.15

0.23

0.54

1 .05

1.13

0.63

1.20

1.07

1.06

0.96

0.84

1.04

1.04

1.98

1 .40

1.46

1.23

1.88

_ _

500

0.96

0.71

-

-

1.05

1.12

0.43

-

-

1.15

0.96

0.43

0.61

1.10

-

1.77

1.65

1.29

2.02

0.27

1000

0.89

0.42

0.23

0.49

1.03

0.81

0.35

0.65

1.37

1.02

1.10

0.43

0.39

1.27

2.30

2.19

1.70

1.24

1.30

_

(1)

Initial studies performed under EPA Grant 12020-DIS,

"Anaerobic Treatment of Synthetic Organic wastes".

(2)

The mm of gas pressure of a sample divided by mm gas

pressure of control after 300 min; a value less than 1,

indicates inhibition while a value greater than 1.00

indicates degradation.

(3)

(4)

00

Compounds added with a micro-syringe because of solubility

Variable effect dependent upon system volatile acid

concentration.

11

image:

Methanogenic Inhibition

After completion of the initial screening effort, the

need for a test more sensitive for detecting inhibition

to methane bacteria was evident. A Warburg test procedure

was developed similar to that used in the initial

screening studies except that a degradable supplement

of sodium acetate was added to ensure that the

methanogenic bacteria would be functioning at a maximum

rate in a non-food limited situation. This maximum

metabolic rate would also be expected to result in

greater sensitivity to inhibitory materials.

Lawrence and McCarty (13) have measured the rate of

substrate utilization and the various constants for

a formula similar to the Monod relationships for

anaerobic methane fermentation:

dF/dt =

kMS

K

where dF/dt = rate of waste utilization per

unit volume of digester, mass/

volume-time

M

S

k

microorganism

mass/volume

concentration,

= waste concentration, mass/volume

= maximum rate of waste utilization

per unit weight of microorganisms

occuring at high waste concentra-

tion, time-1, k = 8.1 mg/mg-day

for acetate substrate at 35°C, and

= half velocity constant equal to

the waste concentration when dF/dt

is equal to one-half of the

maximum rate, k, mass/volume,

Ks = 154 mg/1 for acetate substrate

at 35°C

Calculation of substrate removal rate relative to the

theoretical maximum at various substrate (acetate)

concentrations is illustrated in Table 2.

12

image:

Methanogenic Inhibition

After completion of the initial screening effort, the

need for a test more sensitive for detecting inhibition

to methane bacteria was evident. A Warburg test procedure

was developed similar to that used in the initial

screening studies except that a degradable supplement

of sodium acetate was added to ensure that the

methanogenic bacteria would be functioning at a maximum

rate in a non-food limited situation. This maximum

metabolic rate would also be expected to result in

greater sensitivity to inhibitory materials.

Lawrence and McCarty (13) have measured the rate of

substrate utilization and the various constants for

a formula similar to the Monod relationships for

anaerobic methane fermentation:

dF/dt =

kMS

K

where dF/dt = rate of waste utilization per

unit volume of digester, mass/

volume-time

M

S

k

microorganism

mass/volume

concentration,

= waste concentration, mass/volume

= maximum rate of waste utilization

per unit weight of microorganisms

occuring at high waste concentra-

tion, time-1, k = 8.1 mg/mg-day

for acetate substrate at 35°C, and

= half velocity constant equal to

the waste concentration when dF/dt

is equal to one-half of the

maximum rate, k, mass/volume,

Ks = 154 mg/1 for acetate substrate

at 35°C

Calculation of substrate removal rate relative to the

theoretical maximum at various substrate (acetate)

concentrations is illustrated in Table 2.

12

image:

TABLE 2

COMPUTATION OF RATE OF SUBSTRATE REMOVAL AT

VARIOUS SUBSTRATE CONCENTRATIONS

Substrate

(a)

'Substrate Removal Rate

Substrate Concentration

Concentration,

mg/1

CO

154

500

1000

1500

2000

dF/dt V

M

8.1

4.05

6.19

7.01

7.34

7.52

Maximum Substrate

V Removal Rate

100

50

76

86

91

93

100

(a) Substrate considered to be acetate.

13

image:

TABLE 2

COMPUTATION OF RATE OF SUBSTRATE REMOVAL AT

VARIOUS SUBSTRATE CONCENTRATIONS

Substrate

(a)

'Substrate Removal Rate

Substrate Concentration

Concentration,

mg/1

CO

154

500

1000

1500

2000

dF/dt V

M

8.1

4.05

6.19

7.01

7.34

7.52

Maximum Substrate

V Removal Rate

100

50

76

86

91

93

100

(a) Substrate considered to be acetate.

13

image:

Assuming that gas production is directly related to

substrate removal rate, the gas production rate would

be similarly dependent on substrate concentration.

A Warburg test was made to determine what level of

added acetate would be required to yield a gas

production rate independent of added feed in the

test situation and type of seed sludge used. Results

are presented in Table 3,

TABLE 3

RATE OF GAS PRODUCTION AT VARIOUS

SUPPLEMENTAL ACETATE LEVELS

Added Acetate

Concentration,

mg/1 Ac~

0

0

500

500

1000

1000

Rate of Gas

Production,

mm/hr

73

75

165

143

142

165

Warburg determination of duplicate

samples at 35°C

The data show an increase in gas production at both

500 and 1000 milligrams of added acetate per liter

over the gas production of the unfed control, with

no significant difference in production between the

two acetate concentrations. Apparently with the

sludge used in these particular experiments,

an added acetate concentration of 500 mg/1 in addition

to the volatile acids contained in the digesting

sludge was sufficient to guarantee a non-food-

limited condition for gas production rate.

1.4

image:

Assuming that gas production is directly related to

substrate removal rate, the gas production rate would

be similarly dependent on substrate concentration.

A Warburg test was made to determine what level of

added acetate would be required to yield a gas

production rate independent of added feed in the

test situation and type of seed sludge used. Results

are presented in Table 3,

TABLE 3

RATE OF GAS PRODUCTION AT VARIOUS

SUPPLEMENTAL ACETATE LEVELS

Added Acetate

Concentration,

mg/1 Ac~

0

0

500

500

1000

1000

Rate of Gas

Production,

mm/hr

73

75

165

143

142

165

Warburg determination of duplicate

samples at 35°C

The data show an increase in gas production at both

500 and 1000 milligrams of added acetate per liter

over the gas production of the unfed control, with

no significant difference in production between the

two acetate concentrations. Apparently with the

sludge used in these particular experiments,

an added acetate concentration of 500 mg/1 in addition

to the volatile acids contained in the digesting

sludge was sufficient to guarantee a non-food-

limited condition for gas production rate.

1.4

image:

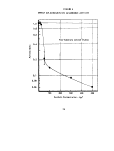

Experimental studies were set up in a fed-Warburg

experiment in a similar fashion to the unfed experiments

except 500 mg/1 acetate (sodium salt used) was added

to each Warburg flask. Also, the phosphate buffer

addition was discontinued due to a possible reaction

with bicarbonate to give an initial surge of carbon

dioxide gas. The sludge itself was found to contain

sufficient alkalinity without additional buffer.

In a non-inhibited, non-food-limited system the

bacterial mass would be expected to operate at the

maximum rate. In a system with a slowly changing

bacterial mass, such as a culture of methanogenic bacteria

with an acknowledged long generation time, the rate of

gas production would then be expected to be linear with

time over short-time intervals compared to the generation

time. These linear plots were used to determine gas-

production rates for both a fed-sludge control and a

similar flask to which a test material was added. Slopes

of the gas production with time were then compared to

determine an activity ratio:

A = gas production rate with test chemical

gas production rate with fed sludge

between the test material and sludge as shown in Figure 2.

An activity ratio of 1.00 would indicate that the test

material was not toxic to methane bacteria which ferment

acetate. A ratio less than one would indicate inhibition

of these bacteria while the magnitude of the ratio would

act as an index of the amount of inhibition. In some

special cases an activity greater than one could be

observed which would indicate fermentation of a material

through a pathway other than methane production from

acetate - for example, fermentation of propionate to

acetate or direct fermentation of a material such

as methanol. Since the test biomass used was

obtained from a domestic digester with no acclimation

to petrochemical waste, the results should provide a

minimum chemical concentration of the test material

resulting in inhibition. Acclimation would result in

less sensitivity to the test chemical or some greater

concentration for the same inhibition. Results of a

typical Warburg are presented in Figure 3.

15

image:

Experimental studies were set up in a fed-Warburg

experiment in a similar fashion to the unfed experiments

except 500 mg/1 acetate (sodium salt used) was added

to each Warburg flask. Also, the phosphate buffer

addition was discontinued due to a possible reaction

with bicarbonate to give an initial surge of carbon

dioxide gas. The sludge itself was found to contain

sufficient alkalinity without additional buffer.

In a non-inhibited, non-food-limited system the

bacterial mass would be expected to operate at the

maximum rate. In a system with a slowly changing

bacterial mass, such as a culture of methanogenic bacteria

with an acknowledged long generation time, the rate of

gas production would then be expected to be linear with

time over short-time intervals compared to the generation

time. These linear plots were used to determine gas-

production rates for both a fed-sludge control and a

similar flask to which a test material was added. Slopes

of the gas production with time were then compared to

determine an activity ratio:

A = gas production rate with test chemical

gas production rate with fed sludge

between the test material and sludge as shown in Figure 2.

An activity ratio of 1.00 would indicate that the test

material was not toxic to methane bacteria which ferment

acetate. A ratio less than one would indicate inhibition

of these bacteria while the magnitude of the ratio would

act as an index of the amount of inhibition. In some

special cases an activity greater than one could be

observed which would indicate fermentation of a material

through a pathway other than methane production from

acetate - for example, fermentation of propionate to

acetate or direct fermentation of a material such

as methanol. Since the test biomass used was

obtained from a domestic digester with no acclimation

to petrochemical waste, the results should provide a

minimum chemical concentration of the test material

resulting in inhibition. Acclimation would result in

less sensitivity to the test chemical or some greater

concentration for the same inhibition. Results of a

typical Warburg are presented in Figure 3.

15

image:

c

o

•rl

V

<J

3

•O

0

M

n

O

FIGURE 2

FED-WARBURG DATA COLLECTION AND HANDLING

Control

Typical Feed Would Consist

of:

1. Sludge

2. Dilution Water

3. Sodium Acetate

(500 mg/1 Ac)

Time

a

o

•rl

•P

U

3

TJ

O

cn

CJ

O

Feed

Test Flask

Typical Feed Would Consist

of:

Sludge

Dilution Water

Sodium Acetate Feed

(500 mg/1 Ac)

4. Test Material

Time

Activity Ratio A = T/S

16

image:

c

o

•rl

V

<J

3

•O

0

M

n

O

FIGURE 2

FED-WARBURG DATA COLLECTION AND HANDLING

Control

Typical Feed Would Consist

of:

1. Sludge

2. Dilution Water

3. Sodium Acetate

(500 mg/1 Ac)

Time

a

o

•rl

•P

U

3

TJ

O

cn

CJ

O

Feed

Test Flask

Typical Feed Would Consist

of:

Sludge

Dilution Water

Sodium Acetate Feed

(500 mg/1 Ac)

4. Test Material

Time

Activity Ratio A = T/S

16

image:

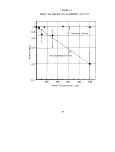

FIGUHE 3

TYPICAL WARBURG RESPIROMETER TEST DATA

0

u

1

800

700

600

500

400

300

200

100

Acrolein, 10 mg/1

(119 mm/hr)

Sludge/Acetate

(111 mm/hr)

Acrolein, 20 mg/1

(lp3 mm/hr)

Sludge only (77 mm,

520-250 - 77 mm/hr

*3 . O

Acrolein, 50 mg/1

(31 mm/hr)

275-165 = 31 mm/hr

Rate Calculation

Period

12345

Time, hours

Activity ratio calculation:

Slope of Test Unit

'hr)

STope of Acetate Control

or

31 mm/hr

111 mm/hr

0.28 for 50 mg/1

acrolein concn.

17

image:

FIGUHE 3

TYPICAL WARBURG RESPIROMETER TEST DATA

0

u

1

800

700

600

500

400

300

200

100

Acrolein, 10 mg/1

(119 mm/hr)

Sludge/Acetate

(111 mm/hr)

Acrolein, 20 mg/1

(lp3 mm/hr)

Sludge only (77 mm,

520-250 - 77 mm/hr

*3 . O

Acrolein, 50 mg/1

(31 mm/hr)

275-165 = 31 mm/hr

Rate Calculation

Period

12345

Time, hours

Activity ratio calculation:

Slope of Test Unit

'hr)

STope of Acetate Control

or

31 mm/hr

111 mm/hr

0.28 for 50 mg/1

acrolein concn.

17

image:

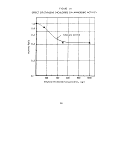

In order to compare the sensitivity of the method and

the reliability of measuring changes in activity

between various Warburg flasks, a study was made in

which 17 flasks were filled with an identical fed sludge

and the variation in linear gas production rates was

measured. A standard deviation of 4.6 mm/hr from the

mean of 27.4 mm/hr or 16 percent was noted in the

reproducibility study. In addition, examination of

the greatest number of data points collected for a

given concentration of a particular chemical (300 mg/1

phenol, 9 replicates) indicated a standard deivation

of 27 percent (±.19) of the mean activity ratio of 0.69.

A listing of the types and structures of chemicals

tested in the Warburg experiments is included in

Table 4, while the results from the non-food limited

Warburg studies are presented in Table 5. Rather

than the three classifications available in the substrate-

limiting studies, only two are generally available

with the non-substrate-limiting tests, i.e.,

inhibitory or non-inhibitory. A compilation of the

inhibition classifications obtained in the Warburg

studies is provided in Table 6 for a comparison of

the results of the two methods.

A gross comparison of the two experimental techniques

indicates that when inhibition was observed in the

substrate-limited experiments it was also observed in

the non-substrate limited experiments (e.g., croton-

aldehyde, acrylonitrile, and ethyl acrylate). However,

in some cases inhibition was evidenced in the non-

substrate-limited experiments where none was seen

with limited substrate (methyl isobutyl ketone and

phenol). Also, inhibition was generally more severe

in the non-limited experiments (crotonaldehyde,

acrylonitrile, 2-methyl-5-ethyl pyridine, and ethyl

acrylate). The more rapid metabolic rate in the non-

substrate-limited test provides one explanation for

the greater sensitivity. Examination of the gas

production occurring in the two types of tests and

the resulting activity ratio provides another key

to the more severe inhibition seen in the non-

substrate-limited tests. The activity ratio (A)

for any test may be expressed as

MT + 0

A = —

MC + °C

18

image:

In order to compare the sensitivity of the method and

the reliability of measuring changes in activity

between various Warburg flasks, a study was made in

which 17 flasks were filled with an identical fed sludge

and the variation in linear gas production rates was

measured. A standard deviation of 4.6 mm/hr from the

mean of 27.4 mm/hr or 16 percent was noted in the

reproducibility study. In addition, examination of

the greatest number of data points collected for a

given concentration of a particular chemical (300 mg/1

phenol, 9 replicates) indicated a standard deivation

of 27 percent (±.19) of the mean activity ratio of 0.69.

A listing of the types and structures of chemicals

tested in the Warburg experiments is included in

Table 4, while the results from the non-food limited

Warburg studies are presented in Table 5. Rather

than the three classifications available in the substrate-

limiting studies, only two are generally available

with the non-substrate-limiting tests, i.e.,

inhibitory or non-inhibitory. A compilation of the

inhibition classifications obtained in the Warburg

studies is provided in Table 6 for a comparison of

the results of the two methods.

A gross comparison of the two experimental techniques

indicates that when inhibition was observed in the

substrate-limited experiments it was also observed in

the non-substrate limited experiments (e.g., croton-

aldehyde, acrylonitrile, and ethyl acrylate). However,

in some cases inhibition was evidenced in the non-

substrate-limited experiments where none was seen

with limited substrate (methyl isobutyl ketone and

phenol). Also, inhibition was generally more severe

in the non-limited experiments (crotonaldehyde,

acrylonitrile, 2-methyl-5-ethyl pyridine, and ethyl

acrylate). The more rapid metabolic rate in the non-

substrate-limited test provides one explanation for

the greater sensitivity. Examination of the gas

production occurring in the two types of tests and

the resulting activity ratio provides another key

to the more severe inhibition seen in the non-

substrate-limited tests. The activity ratio (A)

for any test may be expressed as

MT + 0

A = —

MC + °C

18

image:

TABLE 4

CHEMICAL STRUCTURES EVALUATED IN WARBURG

INHIBITION STUDIES

Chemical

Formula

Alcohols:

n-Butanol(a)

sec-Butanol(a)

t-Butanol(a,b)

Allyl alcohol(a)

2-Ethyl-l-hexanol(b)

Aldehydes:

Formaldehyde(a)

CrotonaIdehyde(a,b)

Acrolein(a)

Ketones:

Acetone(a)

Methyl isobutyl ketone(a,b)

Isophorone(b)

OH

I

CHoC-OH

3CH3

CH2=CHCH2-OH

CH3CH2CH2CH2CHCH2-OH

CH2CH3

H2C=0

CH3C=CC=O

H HH

CH2=CHCH

O

0

CH3CCH3

O

CHQCHCH0CCH

CH3

O

n

^c^

H9C CH

£\ II

o-C C-CH

19

image:

TABLE 4

CHEMICAL STRUCTURES EVALUATED IN WARBURG

INHIBITION STUDIES

Chemical

Formula

Alcohols:

n-Butanol(a)

sec-Butanol(a)

t-Butanol(a,b)

Allyl alcohol(a)

2-Ethyl-l-hexanol(b)

Aldehydes:

Formaldehyde(a)

CrotonaIdehyde(a,b)

Acrolein(a)

Ketones:

Acetone(a)

Methyl isobutyl ketone(a,b)

Isophorone(b)

OH

I

CHoC-OH

3CH3

CH2=CHCH2-OH

CH3CH2CH2CH2CHCH2-OH

CH2CH3

H2C=0

CH3C=CC=O

H HH

CH2=CHCH

O

0

CH3CCH3

O

CHQCHCH0CCH

CH3

O

n

^c^

H9C CH

£\ II

o-C C-CH

19

image:

TABLE 4 (CONT'D)

Ethyl acetate(b)

Ethylene glycol(a,b)

Diethylene glycol(a)

Tetralin(b)

Sodium acetate(b)

Kerosene(a)

Sodium aerylate (a)

Inorganics

Cobalt chloride(a)

Hydrochloric acid(a)

Mercuric chloride(a)

CH3CH2-O-CCH3

CH2-OH

CH2-OH

CH2-OH

CH2-0-CH2CH2-OH

CH3C-ONa

hydrocarbon 150-300°C

H °

CH2=C-C-ONa

CoCl,

HC1

HgCl,

(a) Tested in non-food-limited Warburg.

(b) Tested in Warburg with unfed sludge

20

image:

TABLE 4 (CONT'D)

Ethyl acetate(b)

Ethylene glycol(a,b)

Diethylene glycol(a)

Tetralin(b)

Sodium acetate(b)

Kerosene(a)

Sodium aerylate (a)

Inorganics

Cobalt chloride(a)

Hydrochloric acid(a)

Mercuric chloride(a)

CH3CH2-O-CCH3

CH2-OH

CH2-OH

CH2-OH

CH2-0-CH2CH2-OH

CH3C-ONa

hydrocarbon 150-300°C

H °

CH2=C-C-ONa

CoCl,

HC1

HgCl,

(a) Tested in non-food-limited Warburg.

(b) Tested in Warburg with unfed sludge

20

image:

TABLE 4 (CONT'D)

Nitrogen Containing:

Diethylamine(a)

Ethylene diamine(a)

AeryIonitrile(a,b)

CH2CH3

NH

X

CH2CH3

NH2-CH2CH2-NH,

CH0=CHC=N

2

HC C-CH

I! I

2-Methyl-5-ethyl pyridine(a,b) CH~CH0 — C „ CH

J * ^C^

H

N-N-dimethylaniline(b)

Aromatic:

Phenol (a, b)

Ethyl benzene (b)

Sodium benzoate(a)

Miscellaneous ;

Chloroform(a)

Ethylene dichloride(b)

Ethyl acrylate(a,b)

Dodecane(b)

Dextrose (a ,b)

N(CH3)2

j-CH2CH3

C-ONa

o

CHC13

C1-CH2CH2-C1

O

CH3CH2-0-CCH=CH2

CH3(CH2)10CH3

C6H12°6

21

image:

TABLE 4 (CONT'D)

Nitrogen Containing:

Diethylamine(a)

Ethylene diamine(a)

AeryIonitrile(a,b)

CH2CH3

NH

X

CH2CH3

NH2-CH2CH2-NH,

CH0=CHC=N

2

HC C-CH

I! I

2-Methyl-5-ethyl pyridine(a,b) CH~CH0 — C „ CH

J * ^C^

H

N-N-dimethylaniline(b)

Aromatic:

Phenol (a, b)

Ethyl benzene (b)

Sodium benzoate(a)

Miscellaneous ;

Chloroform(a)

Ethylene dichloride(b)

Ethyl acrylate(a,b)

Dodecane(b)

Dextrose (a ,b)

N(CH3)2

j-CH2CH3

C-ONa

o

CHC13

C1-CH2CH2-C1

O

CH3CH2-0-CCH=CH2

CH3(CH2)10CH3

C6H12°6

21

image:

image:

image:

8 I

3 Ul

g gs

image:

8 I

3 Ul

g gs

image:

Chemical

TABLE 6

SUMMARY OF EFFECTS OF TESTED MATERIALS

ON ANAEROBIC ACTIVITY

Substrate Non-Substrate

Limited Experiments^ ' Limited Experiments^ '

n-Butanol

sec-Butanol