<pubnumber>600878017</pubnumber>

<title>Microbiological Methods for Monitoring the Environment Water and Wastes</title>

<pages>354</pages>

<pubyear>1978</pubyear>

<provider>NEPIS</provider>

<access>online</access>

<operator>mja</operator>

<scandate>05/18/16</scandate>

<origin>PDF</origin>

<type>single page tiff</type>

<keyword>agar water broth sample laboratory colonies test media fecal tubes sterile microbiological dilution mpn medium filter membrane plate count part</keyword>

<author>Bordner, Robert.; Winter, John A.; Scarpino, Pasquale. Bordner, Robert. ; Winter, John A. ; Scarpino, Pasquale. Environmental Monitoring and Support Laboratory, Cincinnati, Ohio. Environmental Monitoring and Support Laboratory (Cincinnati, Ohio)</author>

<publisher>Environmental Protection Agency, Office of Research and Development, Environmental Monitoring and Support Laboratory ;</publisher>

<subject>Water--Microbiology; Water--Waste; Sewage--Microbiology; Aquatic microbiology; Water analysis; Water quality; Manuals; Potable water; Law enforcement; Monitoring; Surface waters; Coliform bacteria; Feces; Streptococcus; Salmonella; Actinomycetales; Culture media; Counting; Indicator organisms; Laboratory equipment; Enterobacteriaceae; Safety </subject>

<abstract>This first EPA manual contains uniform laboratory and field methods for microbiological analyses of waters and wastewaters, and is recommended in enforcement, monitoring and research activities. The procedures are prepared in detailed, stepwise form for the bench worker. The manual covers coliform, fecal coliform, fecal streptococci, Salmonella, actinomycetes, and Standard Plate Count organisms with the necessary support sections on sampling, equipment, media, basic techniques, safety, and quality assurance. </abstract>

EPA-600/8-78-017

December 1978

MICROBIOLOGICAL METHODS FOR MONITORING

THE ENVIRONMENT

Wafer and Wastes

Edited by

Robert Bordner and John Winter

Environmental Monitoring and Support Laboratory-Cincinnati

Cincinnati, Ohio 45268

and Pasquale Scarpino, University of Cincinnati

Cincinnati, Ohio 45219

Prepared in part under EPA Contract No, 68-03-0431

Project Officer

John Winter

Environmental Monitoring and Support Laboratory

Cincinnati, Ohio 45268

ENVIRONMENTAL MONITORING AND SUPPORT LABORATORY

OFFICE OF RESEARCH AND DEVELOPMENT

U.S. ENVIRONMENTAL PROTECTION AGENCY

CINCINNATI, OHIO 45268

s/Q Printed on Recycled Paper

image:

DISCLAIMER

This report has been reviewed by the Environmental Monitoring and Support Laboratory-

Cincinnati, U.S. Environmental Protection Agency and approved for publication. Mention of trade

names or commercial products does not constitute endorsement or recommendation for use.

MICROBIOLOGICAL MANUAL 1978

image:

DISCLAIMER

This report has been reviewed by the Environmental Monitoring and Support Laboratory-

Cincinnati, U.S. Environmental Protection Agency and approved for publication. Mention of trade

names or commercial products does not constitute endorsement or recommendation for use.

MICROBIOLOGICAL MANUAL 1978

image:

FOREWORD

Environmental measurements are required to determine the quality of ambient waters and the

Character of waste effluents. The Environmental Monitoring and Support Laboratory (EMSL^—

Cincinnati conducts research to: • • ••'*•'•

* Develop and evaluate techniques to measure the presence and concentration of

physical, chemical, and radiological pollutants in water, wastewater, bottom

sediments, and solid waste.

* Investigate methods for the concentration, recovery, and identification of viruses,

bacteria and other microorganisms in water.

* Conduct studies to determine the responses of aquatic organisms to water quality.

• Conduct an Agency-wide quality assurance program to assure standardization and

quality control of systems for monitoring water and wastewater.

This publication of EMSL-Cincinnati, contains the methods selected by consensus of EPA

senior microbiologists for parameters of interest to the Agency. Federal agencies, states,

municipalities, universities, private laboratories, and industry should find this manual of assistanpe

in monitoring and controlling microbiological pollution in the environment.

DwightG. Ballinger

Director, EMSL-Cincinnati

image:

FOREWORD

Environmental measurements are required to determine the quality of ambient waters and the

Character of waste effluents. The Environmental Monitoring and Support Laboratory (EMSL^—

Cincinnati conducts research to: • • ••'*•'•

* Develop and evaluate techniques to measure the presence and concentration of

physical, chemical, and radiological pollutants in water, wastewater, bottom

sediments, and solid waste.

* Investigate methods for the concentration, recovery, and identification of viruses,

bacteria and other microorganisms in water.

* Conduct studies to determine the responses of aquatic organisms to water quality.

• Conduct an Agency-wide quality assurance program to assure standardization and

quality control of systems for monitoring water and wastewater.

This publication of EMSL-Cincinnati, contains the methods selected by consensus of EPA

senior microbiologists for parameters of interest to the Agency. Federal agencies, states,

municipalities, universities, private laboratories, and industry should find this manual of assistanpe

in monitoring and controlling microbiological pollution in the environment.

DwightG. Ballinger

Director, EMSL-Cincinnati

image:

PREFACE

The Federal Water Pollution Control Act Amendments of 1972, the Marine Protection,

Research, and Sanctuaries Act of 1972, and the Safe Drinking Water Act of 1974, require that EPA

develop and select methods for environmental monitoring and research on public and private

water supplies, rivers, lakes, ground waters, wastewaters and the marine environment for the

purposes of setting and enforcing environmental standards and ultimately enhancing the quality of

the environment. This manual of methodology supports these needs.

Under the direction of a Steering Committee formed for the development of an Agency

microbiology manual, a seminar was held among representative Agency microbiologists in San

Francisco, January, 1973. Assignments were made to committee members for the preparation of

first draft material. The basic design, format and content of the manual, were established and the

first drafts presented and reviewed at the second meeting of the Committee in January, 1974 at

Cincinnati.

The drafts submitted by the Steering Committee members were formatted and developed into

the initial version under EPA Contract No. 68-03-0431 by Dr. Pasquale Scarpino, Professor of

Environmental Engineering, Department of Civil and Environmental Engineering, University of

Cincinnati, working with the two EPA editors: Robert Bordner, Chief Microbiology Section,

Biological Methods Branch and John Winter, Chief, Quality Assurance Branch, both of EMSL-

Cincinnati. Subsquently, these editors added technical detail and the necessary information

reflecting Agency policies. Valuable source documents for This Manual were Current Practices in

Water Microbiology, National Training and Operational Technology Center and Handbook for

Evaluating Water Bacteriological Laboratories, Municipal Environmental Research Center, both of

U.S. EPA, Cincinnati, Ohio. The refined product is presented here.

Comments or questions concerning the manual should be directed to:

Robert Bordner or John Winter

U.S. Environmental Protection Agency

EMSC-Cincinnati

Cincinnati, OH 45268

<SER*\ MICROBIOLOGICAL MANUAL 1978

image:

PREFACE

The Federal Water Pollution Control Act Amendments of 1972, the Marine Protection,

Research, and Sanctuaries Act of 1972, and the Safe Drinking Water Act of 1974, require that EPA

develop and select methods for environmental monitoring and research on public and private

water supplies, rivers, lakes, ground waters, wastewaters and the marine environment for the

purposes of setting and enforcing environmental standards and ultimately enhancing the quality of

the environment. This manual of methodology supports these needs.

Under the direction of a Steering Committee formed for the development of an Agency

microbiology manual, a seminar was held among representative Agency microbiologists in San

Francisco, January, 1973. Assignments were made to committee members for the preparation of

first draft material. The basic design, format and content of the manual, were established and the

first drafts presented and reviewed at the second meeting of the Committee in January, 1974 at

Cincinnati.

The drafts submitted by the Steering Committee members were formatted and developed into

the initial version under EPA Contract No. 68-03-0431 by Dr. Pasquale Scarpino, Professor of

Environmental Engineering, Department of Civil and Environmental Engineering, University of

Cincinnati, working with the two EPA editors: Robert Bordner, Chief Microbiology Section,

Biological Methods Branch and John Winter, Chief, Quality Assurance Branch, both of EMSL-

Cincinnati. Subsquently, these editors added technical detail and the necessary information

reflecting Agency policies. Valuable source documents for This Manual were Current Practices in

Water Microbiology, National Training and Operational Technology Center and Handbook for

Evaluating Water Bacteriological Laboratories, Municipal Environmental Research Center, both of

U.S. EPA, Cincinnati, Ohio. The refined product is presented here.

Comments or questions concerning the manual should be directed to:

Robert Bordner or John Winter

U.S. Environmental Protection Agency

EMSC-Cincinnati

Cincinnati, OH 45268

<SER*\ MICROBIOLOGICAL MANUAL 1978

image:

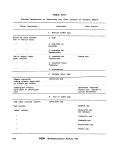

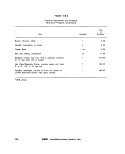

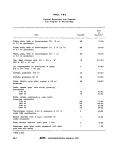

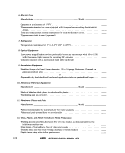

TABLE OF CONTENTS

Page

Foreword iii

Preface iv

Figures vii

Tables x

Acknowledgements xv

PART I INTRODUCTION 1

PART II GENERAL OPERATIONS

A. Sample Collection, Preservation and Storage 5

B. Laboratory Equipment, Techniques and Media 32

C. Isolation and Enumeration of Bacteria 59

D. Selection of Analytical Methods 91

PART III ANALYTICAL METHODOLOGY

A. Standard Plate Count , 101

B. Total Coliforms 108

C. Fecal Coliforms 124

D. Fecal Streptococci 135

E. Salmonella. 154

F. Actinomycetes 186

PART IV QUALITY CONTROL

A. Laboratory Operations 194

B. Statistics for Microbiology 225

C. Analytical Quality Control Procedures 231

PART V LABORATORY MANAGEMENT

A. Development of a Quality Control Program 244

B. Manpower and Analytical Costs 246

C. Safety 259

D. Legal Considerations 277

image:

TABLE OF CONTENTS

Page

Foreword iii

Preface iv

Figures vii

Tables x

Acknowledgements xv

PART I INTRODUCTION 1

PART II GENERAL OPERATIONS

A. Sample Collection, Preservation and Storage 5

B. Laboratory Equipment, Techniques and Media 32

C. Isolation and Enumeration of Bacteria 59

D. Selection of Analytical Methods 91

PART III ANALYTICAL METHODOLOGY

A. Standard Plate Count , 101

B. Total Coliforms 108

C. Fecal Coliforms 124

D. Fecal Streptococci 135

E. Salmonella. 154

F. Actinomycetes 186

PART IV QUALITY CONTROL

A. Laboratory Operations 194

B. Statistics for Microbiology 225

C. Analytical Quality Control Procedures 231

PART V LABORATORY MANAGEMENT

A. Development of a Quality Control Program 244

B. Manpower and Analytical Costs 246

C. Safety 259

D. Legal Considerations 277

image:

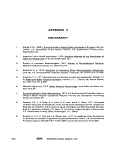

APPENDICES

A. Microbiological Activities under the Water Laws 289

B. Certification of Water Supply Laboratories 297

C. Bibliography 324

INDEX 325

Vi oV MICROBIOLOGICAL MANUAL 1978

image:

APPENDICES

A. Microbiological Activities under the Water Laws 289

B. Certification of Water Supply Laboratories 297

C. Bibliography 324

INDEX 325

Vi oV MICROBIOLOGICAL MANUAL 1978

image:

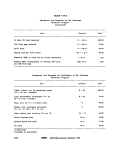

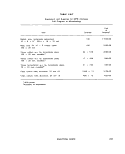

FIGURES

Number Page

Il-A-1 Suggested Sample Containers 7

II-A-2 Demonstration of Technique Used in Grab Sampling of Surface

Waters 9

II-A-3 Weighted Bottle Frame and Sample Bottle for Grab Sampling 10

II-A-4 Zobell J-Z Sampler,.,,.. , ,. 11

ll-A-5 Niskin Depth Sampler 12

II-A-6 New York State Dept of Health Depth Sampler 13

ll-A-7 Kemmerer Depth Sampler 15

II-A-8 Van Donsel-Geldreich Sediment Sampler 16

ll-A-9 Example of a Sample Label 18

M-A-10 Field Data Record 18

II-A-11 Sample Log Sheet 20

II-A-12 Chain of Custody Record..., 21

II-A-13 Sampling a Water Supply Reservoir 23

II-A-14 Sampling a Lake or Impoundment 26

II-A-15 Sampling a Large Stream 27

II-B-1 Finger-mounted Pipetting Device.. 35

ll-B-2 Enlargement of Pipetting Device Tip 35

ll-C-1 Microbiological Bench Cards for MF Analyses 60

ll-C-2 Bench Cards for MPN Analyses 60

II-C-3 Combined Microbiological Bench Card 61

vii

image:

FIGURES

Number Page

Il-A-1 Suggested Sample Containers 7

II-A-2 Demonstration of Technique Used in Grab Sampling of Surface

Waters 9

II-A-3 Weighted Bottle Frame and Sample Bottle for Grab Sampling 10

II-A-4 Zobell J-Z Sampler,.,,.. , ,. 11

ll-A-5 Niskin Depth Sampler 12

II-A-6 New York State Dept of Health Depth Sampler 13

ll-A-7 Kemmerer Depth Sampler 15

II-A-8 Van Donsel-Geldreich Sediment Sampler 16

ll-A-9 Example of a Sample Label 18

M-A-10 Field Data Record 18

II-A-11 Sample Log Sheet 20

II-A-12 Chain of Custody Record..., 21

II-A-13 Sampling a Water Supply Reservoir 23

II-A-14 Sampling a Lake or Impoundment 26

II-A-15 Sampling a Large Stream 27

II-B-1 Finger-mounted Pipetting Device.. 35

ll-B-2 Enlargement of Pipetting Device Tip 35

ll-C-1 Microbiological Bench Cards for MF Analyses 60

ll-C-2 Bench Cards for MPN Analyses 60

II-C-3 Combined Microbiological Bench Card 61

vii

image:

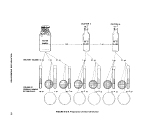

II-C-4 Preparation of Decimal Dilution 63

ll-C-5 Suggested Pattern'for Preparing a Streak Plate , 67

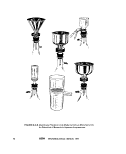

1I-C-6 Membrane Filtration Units Made by Various Manufacturers for

Detection of Bacteria in Aqueous Suspensions ,..„ 72

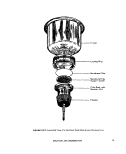

II-C-7 Exploded View of a Stainless Steel Membrane Filtration Unit 73

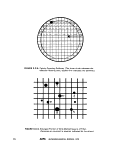

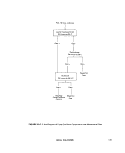

ll-C-8 Colony Counting Pathway 76

ll-C-9 Enlarged Portion of Grid-Marked Square of Filter , 76

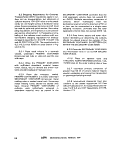

II-C-10 Packaging and Labelling of Microbiological Cultures for

Shipment „ , ..,.. 89

III-A-1 Typical Dilution Series for Standard Plate Count , 103

HI-B-1 Verification of Total Coliform Colonies on the Membrane Filter 115

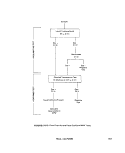

III-B-2 Flow Chart for the Total Coliform MPN Test...., , 116

lll-C-1 Verification of Fecal Coliform Colonies on the Membrane Filter.... 131

lll-C-2 Flow Chart for the Fecal Coliform MPN Test , 133

lll-D-1 Verification Procedure for Fecal Streptococci ; , ,,..,...,. 140

lll-D-2 Isolation and Identification of Fecal Streptococcci, General

Scheme , 141

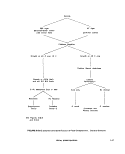

III-D-3 Identification of Fecal Streptococci, Separation of Enterococcus

Group by Species and by Original Source of Culture ,.,... 148

Ill-D-4 Identification of Fecal Streptococci, Separation of Enterococci

from Vegetation, Insect and Animal Sources.. 151

lll-E-1 Scheme for the Concentration, Isolation and Identification of

Salmonella ,..,.,.»...„ 156

lll-E-2 Simplified Scheme for Concentration, Isolation and Identification

of Salmonella..., 157

lll-E-3 Dimensions of the Gauze Swabs 158

IH-E-4 The Gauze Swab in Position , , 159

III-F-1 A Plate Containing Bacterial and Actinornycete Colonies., ,,.. 189

Vlii ©EPA MICROBIOLOGICAL MANUAL 1978

image:

II-C-4 Preparation of Decimal Dilution 63

ll-C-5 Suggested Pattern'for Preparing a Streak Plate , 67

1I-C-6 Membrane Filtration Units Made by Various Manufacturers for

Detection of Bacteria in Aqueous Suspensions ,..„ 72

II-C-7 Exploded View of a Stainless Steel Membrane Filtration Unit 73

ll-C-8 Colony Counting Pathway 76

ll-C-9 Enlarged Portion of Grid-Marked Square of Filter , 76

II-C-10 Packaging and Labelling of Microbiological Cultures for

Shipment „ , ..,.. 89

III-A-1 Typical Dilution Series for Standard Plate Count , 103

HI-B-1 Verification of Total Coliform Colonies on the Membrane Filter 115

III-B-2 Flow Chart for the Total Coliform MPN Test...., , 116

lll-C-1 Verification of Fecal Coliform Colonies on the Membrane Filter.... 131

lll-C-2 Flow Chart for the Fecal Coliform MPN Test , 133

lll-D-1 Verification Procedure for Fecal Streptococci ; , ,,..,...,. 140

lll-D-2 Isolation and Identification of Fecal Streptococcci, General

Scheme , 141

III-D-3 Identification of Fecal Streptococci, Separation of Enterococcus

Group by Species and by Original Source of Culture ,.,... 148

Ill-D-4 Identification of Fecal Streptococci, Separation of Enterococci

from Vegetation, Insect and Animal Sources.. 151

lll-E-1 Scheme for the Concentration, Isolation and Identification of

Salmonella ,..,.,.»...„ 156

lll-E-2 Simplified Scheme for Concentration, Isolation and Identification

of Salmonella..., 157

lll-E-3 Dimensions of the Gauze Swabs 158

IH-E-4 The Gauze Swab in Position , , 159

III-F-1 A Plate Containing Bacterial and Actinornycete Colonies., ,,.. 189

Vlii ©EPA MICROBIOLOGICAL MANUAL 1978

image:

lll-F-2 An Actinomycete Colony Showing the Branching Filaments that

Cause the Fuzzy Appearance of its Border 190

lll-F-3 A Bacterial Colony with its Relatively-Distinct, Smooth Border 190

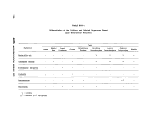

IV-A-1 Equipment Operation Temperature Record 217

IV-B-1 Normal Distribution Curve 228

IV-B-2 Positively-Skewed Distribution Curve 228

V-C-1 Laminar Flow Cabinet 270

V-C-2 Example of Biohazard Sign... ..„ 271

IX

image:

lll-F-2 An Actinomycete Colony Showing the Branching Filaments that

Cause the Fuzzy Appearance of its Border 190

lll-F-3 A Bacterial Colony with its Relatively-Distinct, Smooth Border 190

IV-A-1 Equipment Operation Temperature Record 217

IV-B-1 Normal Distribution Curve 228

IV-B-2 Positively-Skewed Distribution Curve 228

V-C-1 Laminar Flow Cabinet 270

V-C-2 Example of Biohazard Sign... ..„ 271

IX

image:

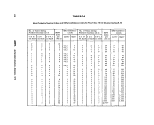

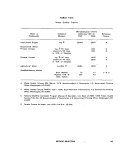

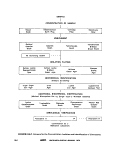

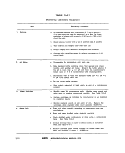

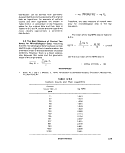

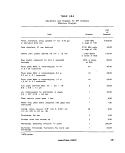

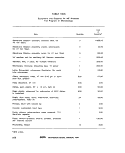

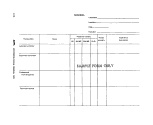

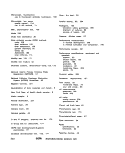

TABLES

Number ' Page

ll-A-1 Sampling Frequency Based on Population 25

H-B-1 Relationship of Steam Pressure to Temperature in the Autoclave. 37

II-C-1 Recommended Filtration Volumes of Samples in MF Analyses....... 64

ll-C-2 Number of Significant Figures (S.F.) Reported 70

H-C-3 Acceptable Limits '. . '. 77

lf-C-4 Most Probable Number Index and 95% Confidence Limits for

Five Tube, Three Dilution Series 82

H-C-5 Most Probable Number Index and 95% Confidence Limits for

Testing Potable Waters 83

II-C-6 Selection of Code Results, Five Tube Series 85

1I-D-1 Approved Test Procedures for the Analyses of Pollutants (40

CFR 136) .". , 93

II-D-2 Water Quality Standards.,! '. ".. 94

H-D-3 Water Quality Criteria 95

II-D-4 Selection of Methods for Problem Samples „.,...... i8

lll-B-1 Differentiation of the Conform and Related Organisms Based on

Biochemical Reactions 120

lll-C-1 Suggested Range of Sample Volumes for Fecal Coliform Tests

Using the Membrane Filter Methods^, 127

lll-E-1 Colonial Appearance of Salmonella and Other Enterics on

Isolation Media 166

III-E-2 Production Rate and Time Requirements of Multitest Systems 174

X &EFA MICROBIOLOGICAL MANUAL 1978

image:

TABLES

Number ' Page

ll-A-1 Sampling Frequency Based on Population 25

H-B-1 Relationship of Steam Pressure to Temperature in the Autoclave. 37

II-C-1 Recommended Filtration Volumes of Samples in MF Analyses....... 64

ll-C-2 Number of Significant Figures (S.F.) Reported 70

H-C-3 Acceptable Limits '. . '. 77

lf-C-4 Most Probable Number Index and 95% Confidence Limits for

Five Tube, Three Dilution Series 82

H-C-5 Most Probable Number Index and 95% Confidence Limits for

Testing Potable Waters 83

II-C-6 Selection of Code Results, Five Tube Series 85

1I-D-1 Approved Test Procedures for the Analyses of Pollutants (40

CFR 136) .". , 93

II-D-2 Water Quality Standards.,! '. ".. 94

H-D-3 Water Quality Criteria 95

II-D-4 Selection of Methods for Problem Samples „.,...... i8

lll-B-1 Differentiation of the Conform and Related Organisms Based on

Biochemical Reactions 120

lll-C-1 Suggested Range of Sample Volumes for Fecal Coliform Tests

Using the Membrane Filter Methods^, 127

lll-E-1 Colonial Appearance of Salmonella and Other Enterics on

Isolation Media 166

III-E-2 Production Rate and Time Requirements of Multitest Systems 174

X &EFA MICROBIOLOGICAL MANUAL 1978

image:

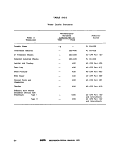

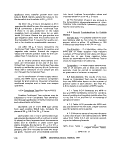

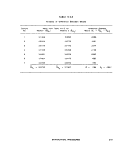

III-E-3 Reported Shelf-Life of Multitest Systems With or Without

Refrigeration 174

HI-E-4 Cost and Source of Multitest Systems 175

lll-E-5 Biochemical Characteristics of the Enterobacteriaceae , 176

IV-A-1 Monitoring Laboratory Equipment.;.......' 212

IV-A-2 Glassware Maintenance , 218

IV-A-3 Laboratory Pure Water for Bacteriological Testing 219

IV-A-4 Quality Control of Media . 220

IVTA-5 Quality Control of Biochemical Tests 222

IV-B-1 Microbiological Results, count/100 ml 225

IV-B-2 Colifdrm Counts and Their. Logarithms 229

IV-B-3 Comparison of Frequency of MPN Data 230

IV-B-4 Comparison of Frequency of Log MPN Data 230

IV-C-1 Raw Sample Data from the Analysis of Chlorinated Sewage

Treatment Plant Effluents.^ '....... ':.......... ...:.. 237

IV-C-2 Logarithmic Transformation of the Data in Table IV-C-1 238

IV-C-3 Analysis of Difference Between Means 241

V-B-1 Estimated Time Required for Twenty MPN Analyses 248

V-B-2 General Equipment and Supplies Minimum Program, Yearly Basis 249

V-B-3 Equipment and Supplies for MF Analyses Minimum Program.... 251

V-B-4 Equipment and Supplies for MPN Analyses Minimum Program 253

V-B-5 General Equipment and Supplies Full Program in Microbiology

Weekly Basis .....I .....; 254

V-B-6 Equipment and Supplies for MF Analyses Full Program in

Microbiology, Weekly Basis...; 256

V-B-7 Equipment and Supplies for MPN Analyses Full Program in

Microbiology, Weekly Basis 257

V-B-8 Media for Full Program in Microbiology Laboratory Usage for

each Week/100 Samples : 258

XI

image:

III-E-3 Reported Shelf-Life of Multitest Systems With or Without

Refrigeration 174

HI-E-4 Cost and Source of Multitest Systems 175

lll-E-5 Biochemical Characteristics of the Enterobacteriaceae , 176

IV-A-1 Monitoring Laboratory Equipment.;.......' 212

IV-A-2 Glassware Maintenance , 218

IV-A-3 Laboratory Pure Water for Bacteriological Testing 219

IV-A-4 Quality Control of Media . 220

IVTA-5 Quality Control of Biochemical Tests 222

IV-B-1 Microbiological Results, count/100 ml 225

IV-B-2 Colifdrm Counts and Their. Logarithms 229

IV-B-3 Comparison of Frequency of MPN Data 230

IV-B-4 Comparison of Frequency of Log MPN Data 230

IV-C-1 Raw Sample Data from the Analysis of Chlorinated Sewage

Treatment Plant Effluents.^ '....... ':.......... ...:.. 237

IV-C-2 Logarithmic Transformation of the Data in Table IV-C-1 238

IV-C-3 Analysis of Difference Between Means 241

V-B-1 Estimated Time Required for Twenty MPN Analyses 248

V-B-2 General Equipment and Supplies Minimum Program, Yearly Basis 249

V-B-3 Equipment and Supplies for MF Analyses Minimum Program.... 251

V-B-4 Equipment and Supplies for MPN Analyses Minimum Program 253

V-B-5 General Equipment and Supplies Full Program in Microbiology

Weekly Basis .....I .....; 254

V-B-6 Equipment and Supplies for MF Analyses Full Program in

Microbiology, Weekly Basis...; 256

V-B-7 Equipment and Supplies for MPN Analyses Full Program in

Microbiology, Weekly Basis 257

V-B-8 Media for Full Program in Microbiology Laboratory Usage for

each Week/100 Samples : 258

XI

image:

V-C-1 Laboratory-acquired Infections Related to Personnel and Work 260

V-C-2 Sources of Laboratory-acquired Infections 261

V-C-3 Normal Use Concentration of Disinfectants 267

Xii vyEFVX MICROBIOLOGICAL MANUAL 1978

image:

V-C-1 Laboratory-acquired Infections Related to Personnel and Work 260

V-C-2 Sources of Laboratory-acquired Infections 261

V-C-3 Normal Use Concentration of Disinfectants 267

Xii vyEFVX MICROBIOLOGICAL MANUAL 1978

image:

THE MICROBIOLOGY METHODS STEERING COMMITTEE

OF EPA

Cochairpersons: Robert Bordner and John Winter

Environmental Monitoring and Support Laboratory-Cincinnati

Members:

William Stang Harold Jeter (retired)

Edwin Geldreich Francis Brezenski

Kathleen Shimmin

xiii

image:

THE MICROBIOLOGY METHODS STEERING COMMITTEE

OF EPA

Cochairpersons: Robert Bordner and John Winter

Environmental Monitoring and Support Laboratory-Cincinnati

Members:

William Stang Harold Jeter (retired)

Edwin Geldreich Francis Brezenski

Kathleen Shimmin

xiii

image:

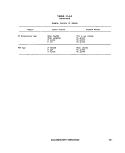

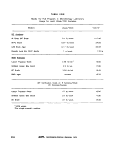

CONTRIBUTORS BY SECTION

Sampling '*•

William Stang

NEIC-Denver

General Laboratory Equipment/Media

Robert Bordner and John Winter

EMSL-Cincinnati

Pasquale Scarpino

UC Dept. of Environ. Engineering

Isolation and Enumeration of Bacteria

Robert Bordner and John Winter

EMSL-Cincinnati

Pasquale Scarpino

UC Dept. of Environ. Engineering

Selection of Analytical Methods

Robert Bordner and John Winter

EMSL-Cincinnati

Standard Plate Count

Raymond Taylor

MERL-Cincinnati

Total Coliforms

Harold Jeter (retired)

National Training Center

ERC-Cincinnati

Fecal Coliforms

Edwin Geldreich

MERL-Cincinnati

Fecal Streptococci

Francis Brezenski

Region II

Salmonella

Kathleen Shimmin

Alameda Laboratory

Region IX

Donald Spino

MERL-Cincinnati

Actinomycetes

Robert Safferman

EMSL-Cincinnati

Quality Control

Robert Bordner

EMSL-Cincinnati

Development of a Quality Control Program

John Winter

EMSL-Cincinnati

Manpower and Analytical Costs

Robert Bordner and John Winter

EMSL-Cincinnati

Legal Considerations

Dave Shedroff

Office of Enforcement

Washington, DC

Carroll Wills

NEIC-Denver

Safety

Robert Bordner and John Winter

EMSL-Cincinnati

Pasquale Scarpino

UC Dept of Environ. Engineering

MICROBIOLOGICAL MANUAL 1978

image:

CONTRIBUTORS BY SECTION

Sampling '*•

William Stang

NEIC-Denver

General Laboratory Equipment/Media

Robert Bordner and John Winter

EMSL-Cincinnati

Pasquale Scarpino

UC Dept. of Environ. Engineering

Isolation and Enumeration of Bacteria

Robert Bordner and John Winter

EMSL-Cincinnati

Pasquale Scarpino

UC Dept. of Environ. Engineering

Selection of Analytical Methods

Robert Bordner and John Winter

EMSL-Cincinnati

Standard Plate Count

Raymond Taylor

MERL-Cincinnati

Total Coliforms

Harold Jeter (retired)

National Training Center

ERC-Cincinnati

Fecal Coliforms

Edwin Geldreich

MERL-Cincinnati

Fecal Streptococci

Francis Brezenski

Region II

Salmonella

Kathleen Shimmin

Alameda Laboratory

Region IX

Donald Spino

MERL-Cincinnati

Actinomycetes

Robert Safferman

EMSL-Cincinnati

Quality Control

Robert Bordner

EMSL-Cincinnati

Development of a Quality Control Program

John Winter

EMSL-Cincinnati

Manpower and Analytical Costs

Robert Bordner and John Winter

EMSL-Cincinnati

Legal Considerations

Dave Shedroff

Office of Enforcement

Washington, DC

Carroll Wills

NEIC-Denver

Safety

Robert Bordner and John Winter

EMSL-Cincinnati

Pasquale Scarpino

UC Dept of Environ. Engineering

MICROBIOLOGICAL MANUAL 1978

image:

ACKNOWLEDGEMENTS

The Committee wishes to acknowledge the many EPA microbiologists and others who

participated in the development or review of the manual. These include, in regional and program

order: .

Region I

Howard Davis and Edward Gritsavage •

Regional Laboratory

Needham Heights, MA

Victor Cabelli, Alfred Dufour and Morris Levin

Environmental Research Laboratory

Narragansett, RI •••...-,..

Region II

Isidore Seidenberg (retired)

Edison Water Laboratory

Edison, NJ

Region III .

Leonard Guarraia Don Lear' . '

Office of Water & Hazardous Materials Annapolis Field Station

Washington, DC Annapolis, MD

Region IV

Bobby Joe Carroll and Ralph Gentry A! Bourquin

S & A Division, SERL Pensacola Station

Athens, GA Pensacola, FL

Region V

James Adams

Central Regional Laboratory

Chicago, 1L

Region VI ,

Harold Cumiford

Houston Facility

Houston, TX

Region VII

Carl Bailey

Regional Laboratory

Kansas City, MO

- xv

image:

ACKNOWLEDGEMENTS

The Committee wishes to acknowledge the many EPA microbiologists and others who

participated in the development or review of the manual. These include, in regional and program

order: .

Region I

Howard Davis and Edward Gritsavage •

Regional Laboratory

Needham Heights, MA

Victor Cabelli, Alfred Dufour and Morris Levin

Environmental Research Laboratory

Narragansett, RI •••...-,..

Region II

Isidore Seidenberg (retired)

Edison Water Laboratory

Edison, NJ

Region III .

Leonard Guarraia Don Lear' . '

Office of Water & Hazardous Materials Annapolis Field Station

Washington, DC Annapolis, MD

Region IV

Bobby Joe Carroll and Ralph Gentry A! Bourquin

S & A Division, SERL Pensacola Station

Athens, GA Pensacola, FL

Region V

James Adams

Central Regional Laboratory

Chicago, 1L

Region VI ,

Harold Cumiford

Houston Facility

Houston, TX

Region VII

Carl Bailey

Regional Laboratory

Kansas City, MO

- xv

image:

Region VIII

John Manhart

Regional Laboratory, Denver Federal Center

Denver, CO

Region IX

Harold Scotten

Alameda Laboratory

Alameda, CA

Region X

George J. Vasconcelos and Richard Bauer

Regional Laboratory

Seattle, WA

Martin Knittel

Environmental Research Laboratory

Corvallis, OR

Ronald Gordon

Alaska Water Laboratory

College, AK

Cincinnati Environmental Research Center

Joseph Santner and Rocco Russomanno

National Training Center

Martin Allen, Harry Nash and Don Reasoner

Municipal Environmental Research Laboratory

Louis Resi

Division of Technical Support

Bernard Kenner (retired)

Municipal Environmental Reserach Laboratory (AWTRL)

Paul Britton, Terry Covert and Herbert Manning

Environmental Monitoring and Support Laboratory

Elmer Akin and Walter Jakubowski

Health Effects Research Laboratory

PREPARATION OF THIS VOLUME

The editors acknowledge gratefully the excellent technical skills of organization, proofreading,

typing and computerized text editing performed by M. Mary Sullivan, Her contribution of hard work

and sacrifice of personal time to this manual cannot be overstated.

XVi V>EPA MICROBIOLOGICAL MANUAL 1978

image:

Region VIII

John Manhart

Regional Laboratory, Denver Federal Center

Denver, CO

Region IX

Harold Scotten

Alameda Laboratory

Alameda, CA

Region X

George J. Vasconcelos and Richard Bauer

Regional Laboratory

Seattle, WA

Martin Knittel

Environmental Research Laboratory

Corvallis, OR

Ronald Gordon

Alaska Water Laboratory

College, AK

Cincinnati Environmental Research Center

Joseph Santner and Rocco Russomanno

National Training Center

Martin Allen, Harry Nash and Don Reasoner

Municipal Environmental Research Laboratory

Louis Resi

Division of Technical Support

Bernard Kenner (retired)

Municipal Environmental Reserach Laboratory (AWTRL)

Paul Britton, Terry Covert and Herbert Manning

Environmental Monitoring and Support Laboratory

Elmer Akin and Walter Jakubowski

Health Effects Research Laboratory

PREPARATION OF THIS VOLUME

The editors acknowledge gratefully the excellent technical skills of organization, proofreading,

typing and computerized text editing performed by M. Mary Sullivan, Her contribution of hard work

and sacrifice of personal time to this manual cannot be overstated.

XVi V>EPA MICROBIOLOGICAL MANUAL 1978

image:

PART I. INTRODUCTION

As the only direct measures of pollution by man and other warm-blooded animals,

microbiological parameters contribute unique information on water and wastewater quality and

public health risk from waterborne disease. Microbiological analyses are conducted to:

Monitor ambient water quality for recreational, industrial, agricultural and water supply uses,

Assure the safety of potable water

Monitor municipal and industrial discharges.

Identify the sources of bacterial pollutants,

and evaluate water resources.

Role of the Aquatic Microbiologist

Although their primary role is to produce valid data for management decisions,

microbiologists should also participate in survey planning and evaluation, develop new microbjal

parameters and methodology, consult on microbiological problems, establish and monitor criteria

and standards, testify in administrative hearings and court cases, train laboratory staffs and

research special problems. Microbiologists should also go beyond sanitary microbiology to solve

taste and odor problems, to study microbiological transformations, and to apply other

measurements to the aquatic ecosystem.

Scope of the Microbiology Manual Series

This EPA manual provides uniform laboratory and field methods for microbiological analyses

of the environment. The analytical methods are standardized procedures recommended for use in

enforcement, monitoring and research. However, they are not intended to inhrbit or prevent

methods research and development. Exploratory and developmental methods are compiled sepa-

rately for evaluation but are part of the EPA Microbiology Manual Series.

The environmental areas covered will include:

* All waters — fresh, estuarine, marine, shellfish-growing, agricultural, ground, surface,

finished, recreational and industrial processing.

INTRODUCTION

image:

PART I. INTRODUCTION

As the only direct measures of pollution by man and other warm-blooded animals,

microbiological parameters contribute unique information on water and wastewater quality and

public health risk from waterborne disease. Microbiological analyses are conducted to:

Monitor ambient water quality for recreational, industrial, agricultural and water supply uses,

Assure the safety of potable water

Monitor municipal and industrial discharges.

Identify the sources of bacterial pollutants,

and evaluate water resources.

Role of the Aquatic Microbiologist

Although their primary role is to produce valid data for management decisions,

microbiologists should also participate in survey planning and evaluation, develop new microbjal

parameters and methodology, consult on microbiological problems, establish and monitor criteria

and standards, testify in administrative hearings and court cases, train laboratory staffs and

research special problems. Microbiologists should also go beyond sanitary microbiology to solve

taste and odor problems, to study microbiological transformations, and to apply other

measurements to the aquatic ecosystem.

Scope of the Microbiology Manual Series

This EPA manual provides uniform laboratory and field methods for microbiological analyses

of the environment. The analytical methods are standardized procedures recommended for use in

enforcement, monitoring and research. However, they are not intended to inhrbit or prevent

methods research and development. Exploratory and developmental methods are compiled sepa-

rately for evaluation but are part of the EPA Microbiology Manual Series.

The environmental areas covered will include:

* All waters — fresh, estuarine, marine, shellfish-growing, agricultural, ground, surface,

finished, recreational and industrial processing.

INTRODUCTION

image:

* All wastewaters of microbiological concern - domestic waste effluents, industrial

wastes such as food, dairy, meat, tanning, sugar, textile, pulp and paper, shellfish

processing and agricultural wastes such as feedlot and irrigation runoff.

• Other areas of the environment - air, sediments, soils, sludges, oils, leachates,

vegetation, etc.

Coverage of the First Edition of the Manual

Although the scope of the Manual Series is broad and inclusive of many parameters and

sample types, the first edition describes primarily the analytical methods that meet the immediate

needs of the Agency. These are the key parameters that are accepted and used for water quality,

compliance monitoring and enforcement under Federal Water Pollution Control Act, PL 92-500,

Marine Protection, Research, and Sanctuaries Act, PL 92-532 and the Safe Drinking Water Act, PL

93-523. The necessary supportive sections include: sample collection, equipment and techniques,

cultural media, glassware preparation, quality control, data handling, safety, legal considerations

and selection of analytical methods.

Focus of the Manual

This Manual is intended for use by the supervisor or analyst who may be a professional

microbiologist, a technician, chemist, engineer or plant operator. Regardless of other skills, the

supervisor and analyst should have received at least two weeks training in each parameter from a

federal or state agency or from a university.

To assist the newanalyst, Part II has been prepared as a basic discussion on laboratory operations

and for general guidance to permit use of the manual by those required to do microbiological

analyses. The trained analyst will be familiar and knowledgeable of most of these techniques.

The analytical procedures in Part HI are written in a stepwise manner so that the manual can be

used both at bench level and as a reference book. Part IV emphasizes the important, but often neglect-

ed need for quality control in microbiological analyses, while Part V describes general considerations

for laboratory management.

Objectives

The objectives of This Manual are to:

* Select the best method currently available for use in the environmental monitoring,

compliance monitoring, enforcement and research activities of the Agency,

» Establish uniform application of microbiological methods so that only the best methods

are used and perpetuated, data from different laboratories or surveys can be fairly

compared and/or results can be stored in a common data bank, e.g., STORET, for later

use.

» Provide guidance on the use of these methods, their" advantages, limitations and

application to various types of water and wastes.

• Establish recognized procedures for method selection and evaluation that will form the

baseline against which othertests forthe same or new parameters can be measured.

* Emphasize the analytical quality control and management practices that should be

performed in the laboratory to assure valid data.

2 4>EPA MICROBIOLOGICAL MANUAL 1978

image:

* All wastewaters of microbiological concern - domestic waste effluents, industrial

wastes such as food, dairy, meat, tanning, sugar, textile, pulp and paper, shellfish

processing and agricultural wastes such as feedlot and irrigation runoff.

• Other areas of the environment - air, sediments, soils, sludges, oils, leachates,

vegetation, etc.

Coverage of the First Edition of the Manual

Although the scope of the Manual Series is broad and inclusive of many parameters and

sample types, the first edition describes primarily the analytical methods that meet the immediate

needs of the Agency. These are the key parameters that are accepted and used for water quality,

compliance monitoring and enforcement under Federal Water Pollution Control Act, PL 92-500,

Marine Protection, Research, and Sanctuaries Act, PL 92-532 and the Safe Drinking Water Act, PL

93-523. The necessary supportive sections include: sample collection, equipment and techniques,

cultural media, glassware preparation, quality control, data handling, safety, legal considerations

and selection of analytical methods.

Focus of the Manual

This Manual is intended for use by the supervisor or analyst who may be a professional

microbiologist, a technician, chemist, engineer or plant operator. Regardless of other skills, the

supervisor and analyst should have received at least two weeks training in each parameter from a

federal or state agency or from a university.

To assist the newanalyst, Part II has been prepared as a basic discussion on laboratory operations

and for general guidance to permit use of the manual by those required to do microbiological

analyses. The trained analyst will be familiar and knowledgeable of most of these techniques.

The analytical procedures in Part HI are written in a stepwise manner so that the manual can be

used both at bench level and as a reference book. Part IV emphasizes the important, but often neglect-

ed need for quality control in microbiological analyses, while Part V describes general considerations

for laboratory management.

Objectives

The objectives of This Manual are to:

* Select the best method currently available for use in the environmental monitoring,

compliance monitoring, enforcement and research activities of the Agency,

» Establish uniform application of microbiological methods so that only the best methods

are used and perpetuated, data from different laboratories or surveys can be fairly

compared and/or results can be stored in a common data bank, e.g., STORET, for later

use.

» Provide guidance on the use of these methods, their" advantages, limitations and

application to various types of water and wastes.

• Establish recognized procedures for method selection and evaluation that will form the

baseline against which othertests forthe same or new parameters can be measured.

* Emphasize the analytical quality control and management practices that should be

performed in the laboratory to assure valid data.

2 4>EPA MICROBIOLOGICAL MANUAL 1978

image:

Criteria

The first edition of This Manual describes the parameters of health and sanitary significance.

In the future, the criteria for addition of a method to the Manual are:

• The method is required to satisfy new or changing needs of the Agency.

» The method is practical for field and laboratory use. Equipment, supplies and media are

available and the procedure provides results within reasonable time limits.

* The method offers significant advantages over current methods.

• The method has been validated by the developer or by others according to the criteria

for Comparative Testing of Methodology and Method Characterization. (See IV-C-1).

• The method criteria and characterization have been reviewed and accepted by the EPA

Steering Committee for Microbiology.

INTRODUCTION

image:

Criteria

The first edition of This Manual describes the parameters of health and sanitary significance.

In the future, the criteria for addition of a method to the Manual are:

• The method is required to satisfy new or changing needs of the Agency.

» The method is practical for field and laboratory use. Equipment, supplies and media are

available and the procedure provides results within reasonable time limits.

* The method offers significant advantages over current methods.

• The method has been validated by the developer or by others according to the criteria

for Comparative Testing of Methodology and Method Characterization. (See IV-C-1).

• The method criteria and characterization have been reviewed and accepted by the EPA

Steering Committee for Microbiology.

INTRODUCTION

image:

PART II. GENERAL OPERATIONS

This Part describes the general procedures which are applicable to the methods of analysis for

all parameters. The Sections provide the basic background information that must be understood

whan the analytical procedures are carried out. The procedures are divided here into broad areas

of function:

Section A Sample Collection, Preservation and Storage

Section B General Laboratory Equipment, Techniques and Media

Section C Isolation and Enumeration of Bacteria

Section D Selection of Analytical Methodology

MICROBIOLOGICAL MANUAL 1978

image:

PART II. GENERAL OPERATIONS

This Part describes the general procedures which are applicable to the methods of analysis for

all parameters. The Sections provide the basic background information that must be understood

whan the analytical procedures are carried out. The procedures are divided here into broad areas

of function:

Section A Sample Collection, Preservation and Storage

Section B General Laboratory Equipment, Techniques and Media

Section C Isolation and Enumeration of Bacteria

Section D Selection of Analytical Methodology

MICROBIOLOGICAL MANUAL 1978

image:

PART II. GENERAL OPERATIONS

Section A Sample Collection, Preservation and Storage

Collection, preservation and storage of

water samples are critical to the results of

water quality analyses. The data are only as

valid as the water sample,

A sampling program must be planned to

satisfy the objectives of the study yet remain

within the limitations of available manpower,

time and money. The survey should use the

minimum number of samples that adequately

represent the effluent or body of water from

which they are taken. The number of samples

and location of sampling sites should be deter-

mined prior to the survey and must satisfy the

requirements needed to establish water qual-

ity standard or effluent permit violations.

The microbiologist should participate in

the planning which specifies the microbiologi-

cal tests needed, the number of analyses to be

performed, and the equipment required. Con-

sideration should be given to the weather and

other local conditions prior to the formulation

of a final plan. For example, seasonal varia-

tions in water temperature and flows would be

important factors in deciding when to study

the effects of thermal pollution on bacteria.

Sample collectors must know the exact loca-

tion of the sampling sites and be fully trained

in the aseptic technique of sample collection

as well as the use of any specialized sampling

equipment. The sample collector is responsi-

ble for the recording of all pertinent informa-

tion about the sample that might be significant

in the evaluation and interpretation of the

laboratory data or that might be necessary in

potential enforcement action.

This Section is organized as follows:

1. Sample Containers

2. Sampling Techniques

Composite Sampling

Surface Sampling by Hand

Surface Sampling by

Weighted Bottle Frame

Depth Sampling

Soil Sampling

Sediment Sampling

Water Tap Sampling

3. Sample Identification and

Handling

4, Chain of Custody Procedures

5. Selection of Sampling Sites and

Frequency

Potable Water Supplies

Lakes and Impoundments

Stream Sampling

Marine and Estuarine

Sampling

Domestic and Industrial

Waste Discharges

Recreational Waters

Shellfish-Harvesting Waters

Frequency of Sampling

6. Preservation and Transit of

Samples

SAMPLING TECHNIQUES

image:

PART II. GENERAL OPERATIONS

Section A Sample Collection, Preservation and Storage

Collection, preservation and storage of

water samples are critical to the results of

water quality analyses. The data are only as

valid as the water sample,

A sampling program must be planned to

satisfy the objectives of the study yet remain

within the limitations of available manpower,

time and money. The survey should use the

minimum number of samples that adequately

represent the effluent or body of water from

which they are taken. The number of samples

and location of sampling sites should be deter-

mined prior to the survey and must satisfy the

requirements needed to establish water qual-

ity standard or effluent permit violations.

The microbiologist should participate in

the planning which specifies the microbiologi-

cal tests needed, the number of analyses to be

performed, and the equipment required. Con-

sideration should be given to the weather and

other local conditions prior to the formulation

of a final plan. For example, seasonal varia-

tions in water temperature and flows would be

important factors in deciding when to study

the effects of thermal pollution on bacteria.

Sample collectors must know the exact loca-

tion of the sampling sites and be fully trained

in the aseptic technique of sample collection

as well as the use of any specialized sampling

equipment. The sample collector is responsi-

ble for the recording of all pertinent informa-

tion about the sample that might be significant

in the evaluation and interpretation of the

laboratory data or that might be necessary in

potential enforcement action.

This Section is organized as follows:

1. Sample Containers

2. Sampling Techniques

Composite Sampling

Surface Sampling by Hand

Surface Sampling by

Weighted Bottle Frame

Depth Sampling

Soil Sampling

Sediment Sampling

Water Tap Sampling

3. Sample Identification and

Handling

4, Chain of Custody Procedures

5. Selection of Sampling Sites and

Frequency

Potable Water Supplies

Lakes and Impoundments

Stream Sampling

Marine and Estuarine

Sampling

Domestic and Industrial

Waste Discharges

Recreational Waters

Shellfish-Harvesting Waters

Frequency of Sampling

6. Preservation and Transit of

Samples

SAMPLING TECHNIQUES

image:

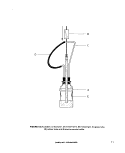

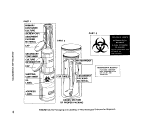

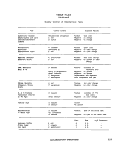

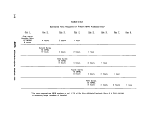

1. Sample Containers

1.1 Sample Bottles: Bottles must be resis-

tant to sterilizing conditions and the solvent

action of water. Wide-mouth borosilicate glass

bottles with screw-cap or ground-glass stopper

or heat-resistant plastic bottles may be used

if they can be sterilized without producing toxic

materials {see suggested sample containers in

Figure II-A-1). Screw-caps must not produce

bacteriostatic or nutritive compounds upon

sterilization.

1.2 Selection and Cleansing of Bottles:

Sample bottles should be at least 125 ml vol-

ume for adequate sampling and for good mixing.

Bottles of 250 ml, 500 ml and 1000 ml volume

are often used for multiple analyses. Discard

bottles which have chips, cracks, and etched

surfaces. Bottle closures must be water-tight.

Before use, thoroughly cleanse bottles and

closures with detergent and hot water, fol-

lowed by a hot water rinse to remove all trace

of detergent. Then rinse them three times with

laboratory-pure water {II-B.6). A test for the

biological examination of glassware where

bacteriostatic or inhibitory residues may

be present, is described in Part 1V-A, 5.1.

1.5 Wrapping Bottles: Protect the tops

and necks of glass stoppered bottles from

contamination by covering them before sterili-

zation with aluminum foil or kraft paper.

1.6 Sterilization of Bottles: Autoclave

glass or heat-resistant plastic bottles at 121 C

for 15 minutes. Alternatively, dry glassware

may be sterilized in a hot air oven at 170 C for

not less than two hours. Ethylene oxide gas

sterilization is acceptable for plastic containers

that are not heat-resistant Sample bottles

sterilized by gas should be stored overnight

before being used to allow the last traces of

gas to dissipate. See Part il-B, 3 for steriliza-

tion procedures.

1.7 Plastic Bags: The commercially-

available bags (Whirl-pak) are a practical sub-

stitute for plastic or glass sample bottles in

sampling soil or sediment. See Figure ll-A-1.

The bags are sealed in manufacture and opened

only at time of sampling. The manufacturer

states that such bags are sterilized.

2. Sampling Techniques

1.3 Dechlorinating Agent: The agent

must be placed in the bottle when water and

wastewater samples containing residual chlo-

rine are anticipated. Add sodium thiosulfate to

the bottle before sterilization at a concentration

of 0.1 ml of a 10 percent solution for each

125 ml {4 oz.J sample volume (1). This concen-

tration will neutralize approximately 15 mg/l

of residue chlorine.

1,4 Chelating Agent: A chelating agent

should be added to sample bottles used to

collect samples suspected of containing

>0.01 mg/liter concentrations of heavy metals

such as copper, nickel or zinc, etc. Add 0.3

ml of a 15 percent solution of ethylenedia-

minetetraacetic acid (EDTA) tetrasodium salt,

for each 125 ml (4 oz.) sample volume prior to

sterilization {2, 3).

Samples are collected by hand or with a

sampling device if (1) depth samples are re-

quired or (2) the sampling site has difficult

access such as a manhole, dock, bridge or

bank adjacent to a surface water.

2,1 Chlorinated Samples: When samples,

such as treated waters, chlorinated wastewa-

ters or recreational waters, are collected, the

sample bottle must contain a dechlorinating

agent (see this Section, 1.3).

2.2 Composite Sampling: |_n no case

should a composite sample be collected for

bacteriological examination. Data from indi-

vidual samples show a range of values. A com-

posite sample will not display this range. Indi-

vidual results will give information about in-

dustrial process variations in flow and compo-

«»EPA MICROBIOLOGICAL MANUAL 1978

image:

1. Sample Containers

1.1 Sample Bottles: Bottles must be resis-

tant to sterilizing conditions and the solvent

action of water. Wide-mouth borosilicate glass

bottles with screw-cap or ground-glass stopper

or heat-resistant plastic bottles may be used

if they can be sterilized without producing toxic

materials {see suggested sample containers in

Figure II-A-1). Screw-caps must not produce

bacteriostatic or nutritive compounds upon

sterilization.

1.2 Selection and Cleansing of Bottles:

Sample bottles should be at least 125 ml vol-

ume for adequate sampling and for good mixing.

Bottles of 250 ml, 500 ml and 1000 ml volume

are often used for multiple analyses. Discard

bottles which have chips, cracks, and etched

surfaces. Bottle closures must be water-tight.

Before use, thoroughly cleanse bottles and

closures with detergent and hot water, fol-

lowed by a hot water rinse to remove all trace

of detergent. Then rinse them three times with

laboratory-pure water {II-B.6). A test for the

biological examination of glassware where

bacteriostatic or inhibitory residues may

be present, is described in Part 1V-A, 5.1.

1.5 Wrapping Bottles: Protect the tops

and necks of glass stoppered bottles from

contamination by covering them before sterili-

zation with aluminum foil or kraft paper.

1.6 Sterilization of Bottles: Autoclave

glass or heat-resistant plastic bottles at 121 C

for 15 minutes. Alternatively, dry glassware

may be sterilized in a hot air oven at 170 C for

not less than two hours. Ethylene oxide gas

sterilization is acceptable for plastic containers

that are not heat-resistant Sample bottles

sterilized by gas should be stored overnight

before being used to allow the last traces of

gas to dissipate. See Part il-B, 3 for steriliza-

tion procedures.

1.7 Plastic Bags: The commercially-

available bags (Whirl-pak) are a practical sub-

stitute for plastic or glass sample bottles in

sampling soil or sediment. See Figure ll-A-1.

The bags are sealed in manufacture and opened

only at time of sampling. The manufacturer

states that such bags are sterilized.

2. Sampling Techniques

1.3 Dechlorinating Agent: The agent

must be placed in the bottle when water and

wastewater samples containing residual chlo-

rine are anticipated. Add sodium thiosulfate to

the bottle before sterilization at a concentration

of 0.1 ml of a 10 percent solution for each

125 ml {4 oz.J sample volume (1). This concen-

tration will neutralize approximately 15 mg/l

of residue chlorine.

1,4 Chelating Agent: A chelating agent

should be added to sample bottles used to

collect samples suspected of containing

>0.01 mg/liter concentrations of heavy metals

such as copper, nickel or zinc, etc. Add 0.3

ml of a 15 percent solution of ethylenedia-

minetetraacetic acid (EDTA) tetrasodium salt,

for each 125 ml (4 oz.) sample volume prior to

sterilization {2, 3).

Samples are collected by hand or with a

sampling device if (1) depth samples are re-

quired or (2) the sampling site has difficult

access such as a manhole, dock, bridge or

bank adjacent to a surface water.

2,1 Chlorinated Samples: When samples,

such as treated waters, chlorinated wastewa-

ters or recreational waters, are collected, the

sample bottle must contain a dechlorinating

agent (see this Section, 1.3).

2.2 Composite Sampling: |_n no case

should a composite sample be collected for

bacteriological examination. Data from indi-

vidual samples show a range of values. A com-

posite sample will not display this range. Indi-

vidual results will give information about in-

dustrial process variations in flow and compo-

«»EPA MICROBIOLOGICAL MANUAL 1978

image:

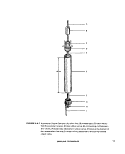

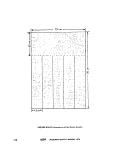

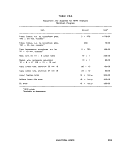

B

FIGURE ll-A-1. Suggested Sample Containers

A Screw-cap Glass or Plastic Bottle.

B Plastic Bag (Whiri-pak).

C Glass Stoppered Bottle.

SAMPLING TECHNIQUES

image:

B

FIGURE ll-A-1. Suggested Sample Containers

A Screw-cap Glass or Plastic Bottle.

B Plastic Bag (Whiri-pak).

C Glass Stoppered Bottle.

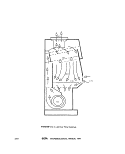

SAMPLING TECHNIQUES

image:

sition. Also, one or more portions that make up

a composite sample may contain toxic or nutri-

tive materials and cause erroneous results.

2.3 Surface Sampling by Hand: A grab

sample is obtained using a sample bottle pre-

pared as described in 1. above. Identify the

sampling site on a chain of custody tag if

required, or on the bottle label and on a field

log sheet (see 3J, Remove the bottle covering

and closure and protect from contamination.

Grasp the bottle at the base with one hand and

plunge the bottle mouth down into the water to

avoid introducing surface scum. Position the

mouth of the bottle into the current away from

the hand of the collector and away from the

side of the sampling platform or boat (see

Figure ll-A-2). The sampling depth should be

15 to 30 cm (6 to 12 inches) below the water

surface. If the water body is static, an artificial

current can be created, by moving the bottle

horizontally in the direction it is pointed and

away from the sampler. Tip the bottle slightly

upwards to allow air to exit and the bottle to

fill. After removal of the bottle from the stream,

pour out a small portion of the sample to allow

an air space of 2.5 to 5 cm (1 to 2 inches)

above each sample for proper mixing of the

sample before analyses. Tightly stopper and

label the bottle.

2A Surface Sampling by Weighted Bot-

tle Frame: When sampling from a bridge or

other structure above a stream or body of

water, the sample collector places the bottle in

a weighted frame (see Figure II-A-3) that holds

the bottle securely. Remove cover and lower

the device to the water. It is preferable to use

nylon rope which does not absorb water and

will not rot. Face the bottle mouth upstream by

swinging the sampling device first down-

stream, and then allow it to drop into the water,

without slack in the rope. Pull the sample de-

vice rapidly upstream and out of the water,

thus simulating the scooping motion of grab

sampling described in 2.3. Take care not to

dislodge dirt or other material that might fall

into the open bottle from the sampling

platform.

2.5 Depth Sampling: Several additional

devices are needed for collection of depth

samples from lakes, reservoirs, estuaries and

the oceans. These depth samplers require low-

ering the sampling device and/or container to

the desired depth, then opening, filling, and

closing the container and returning the device

to the surface. Although depth measurements

are best made with a pre-marked steel cable,

the sample depths can be determined by pre-

measuring and marking the nylon rope at inter-

vals with a non-smearing ink, paint, or finger-

nail polish. The following list of depth sam-

plers is not inclusive but can serve as a guide:

2.5.1 ZoBell J-Z Sampler: This sampler

described by ZoBell in 1941 (4) was designed

for deep sea sampling but is also used in fresh

waters. Figure ll-A-4 shows its general ap-

pearance. It has a metal frame (A), a heavy

metal messenger (B), a sealed glass tube (C)

attached to a rubber tube (D), and a sterile

350 ml glass bottle (E) or a collapsible neo-

prene rubber bulb for shallow waters. The

messenger (B) is released at the surface when

the sampler reaches the 'desired depth, and

breaks the glass tubing (C) at a file mark. The

bent rubber tubing (D) then straightens out and

the water is drawn in several inches from the

sampler. A partial vacuum created by auto-

claving of the sealed unit draws the water into

the bottle.

2.5.2 Niskin Sampler: This is sometimes

called a sterile-bag or "Book" sampler (see

Figure ll-A-5) (5). A messenger triggers the

opening of two plates (A) in V-fashion by spring

power, and causes the sterile plastic bag (B) to

inflate. At the same time a plastic filler tube (C)

leading to the plastic container is cut by a

guillotine knife (D) and the bag fills with water.

The bag is then automatically sealed with a

clamp (E) and the apparatus is brought to the

surface. Samplers are available that will hold

1,2,3, or 5 liters of water.

2.5.3 New York Dept. of Health Depth

Sampler: This device (see Figure ll-A-6) de-

pends upon a vane (A) and lever (B) mechanism

to lift the glass stopper (C) as water inertia is

applied by a sharp upward tug on the line (D)

attached to the apparatus. As the stopper is

lifted, the bottle fills before the detachment of

the stopper from the vane occurs and closes

the sample bottle (6).

MICROBIOLOGICAL MANUAL 1978

image:

sition. Also, one or more portions that make up

a composite sample may contain toxic or nutri-

tive materials and cause erroneous results.

2.3 Surface Sampling by Hand: A grab

sample is obtained using a sample bottle pre-

pared as described in 1. above. Identify the

sampling site on a chain of custody tag if

required, or on the bottle label and on a field

log sheet (see 3J, Remove the bottle covering

and closure and protect from contamination.

Grasp the bottle at the base with one hand and

plunge the bottle mouth down into the water to

avoid introducing surface scum. Position the

mouth of the bottle into the current away from

the hand of the collector and away from the

side of the sampling platform or boat (see

Figure ll-A-2). The sampling depth should be

15 to 30 cm (6 to 12 inches) below the water

surface. If the water body is static, an artificial

current can be created, by moving the bottle

horizontally in the direction it is pointed and

away from the sampler. Tip the bottle slightly

upwards to allow air to exit and the bottle to

fill. After removal of the bottle from the stream,

pour out a small portion of the sample to allow

an air space of 2.5 to 5 cm (1 to 2 inches)

above each sample for proper mixing of the

sample before analyses. Tightly stopper and

label the bottle.

2A Surface Sampling by Weighted Bot-

tle Frame: When sampling from a bridge or

other structure above a stream or body of

water, the sample collector places the bottle in

a weighted frame (see Figure II-A-3) that holds

the bottle securely. Remove cover and lower

the device to the water. It is preferable to use

nylon rope which does not absorb water and

will not rot. Face the bottle mouth upstream by

swinging the sampling device first down-

stream, and then allow it to drop into the water,

without slack in the rope. Pull the sample de-

vice rapidly upstream and out of the water,

thus simulating the scooping motion of grab

sampling described in 2.3. Take care not to

dislodge dirt or other material that might fall

into the open bottle from the sampling

platform.

2.5 Depth Sampling: Several additional

devices are needed for collection of depth

samples from lakes, reservoirs, estuaries and

the oceans. These depth samplers require low-

ering the sampling device and/or container to

the desired depth, then opening, filling, and

closing the container and returning the device

to the surface. Although depth measurements

are best made with a pre-marked steel cable,

the sample depths can be determined by pre-

measuring and marking the nylon rope at inter-

vals with a non-smearing ink, paint, or finger-

nail polish. The following list of depth sam-

plers is not inclusive but can serve as a guide:

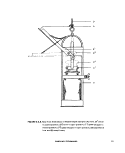

2.5.1 ZoBell J-Z Sampler: This sampler

described by ZoBell in 1941 (4) was designed

for deep sea sampling but is also used in fresh

waters. Figure ll-A-4 shows its general ap-

pearance. It has a metal frame (A), a heavy

metal messenger (B), a sealed glass tube (C)

attached to a rubber tube (D), and a sterile

350 ml glass bottle (E) or a collapsible neo-

prene rubber bulb for shallow waters. The

messenger (B) is released at the surface when

the sampler reaches the 'desired depth, and

breaks the glass tubing (C) at a file mark. The

bent rubber tubing (D) then straightens out and

the water is drawn in several inches from the

sampler. A partial vacuum created by auto-

claving of the sealed unit draws the water into

the bottle.

2.5.2 Niskin Sampler: This is sometimes

called a sterile-bag or "Book" sampler (see

Figure ll-A-5) (5). A messenger triggers the

opening of two plates (A) in V-fashion by spring

power, and causes the sterile plastic bag (B) to

inflate. At the same time a plastic filler tube (C)

leading to the plastic container is cut by a

guillotine knife (D) and the bag fills with water.

The bag is then automatically sealed with a

clamp (E) and the apparatus is brought to the

surface. Samplers are available that will hold

1,2,3, or 5 liters of water.

2.5.3 New York Dept. of Health Depth

Sampler: This device (see Figure ll-A-6) de-

pends upon a vane (A) and lever (B) mechanism

to lift the glass stopper (C) as water inertia is

applied by a sharp upward tug on the line (D)

attached to the apparatus. As the stopper is

lifted, the bottle fills before the detachment of

the stopper from the vane occurs and closes

the sample bottle (6).

MICROBIOLOGICAL MANUAL 1978

image:

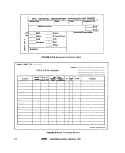

FIGURE II-A-2. Demonstration of Technique Used in Grab Sampling of Surface Waters.

SAMPLING TECHNIQUES

image:

FIGURE II-A-2. Demonstration of Technique Used in Grab Sampling of Surface Waters.

SAMPLING TECHNIQUES

image:

FIGURE II-A-3. Weighted Bottle Frame and Sample Bottle for Grab Sampling.

10

4>EPA MICROBIOLOGICAL MANUAL 1978

image:

FIGURE II-A-3. Weighted Bottle Frame and Sample Bottle for Grab Sampling.

10

4>EPA MICROBIOLOGICAL MANUAL 1978

image:

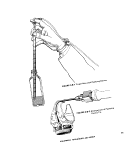

D

B

A

E

FIGURE ll-A-4. Zobell J-Z Sampler. (A) metal frame, (B) messenger, (C) glass tube,

(D) rubber tube and (E) sterile sample bottle.

SAMPLING TECHNIQUES

11

image:

D

B

A

E

FIGURE ll-A-4. Zobell J-Z Sampler. (A) metal frame, (B) messenger, (C) glass tube,

(D) rubber tube and (E) sterile sample bottle.

SAMPLING TECHNIQUES

11

image:

B

FIGURE II-A-5. Niskin Depth Sampler. (A) hinged plates, (B) plastic bag,

(C) plastic filler tube in sheath, (D) guillotine knife and (E)

closure clamp.

12

<&EPA MICROBIOLOGICAL MANUAL 1978

image:

B

FIGURE II-A-5. Niskin Depth Sampler. (A) hinged plates, (B) plastic bag,

(C) plastic filler tube in sheath, (D) guillotine knife and (E)

closure clamp.

12

<&EPA MICROBIOLOGICAL MANUAL 1978

image:

D

A

FIGURE ll-A-6. New York State Dept. of Health Depth Sampler. (A) vane, (B1) lever

in closed position, (B2) lever in open position, (C1) glass stopper in

closed position, (C ) glass stopper in open position, (D) suspension

line, and (E) metal frame.

SAMPLING TECHNIQUES

13

image:

D

A

FIGURE ll-A-6. New York State Dept. of Health Depth Sampler. (A) vane, (B1) lever

in closed position, (B2) lever in open position, (C1) glass stopper in

closed position, (C ) glass stopper in open position, (D) suspension

line, and (E) metal frame.

SAMPLING TECHNIQUES

13

image:

2«5-4 Kemmerer Sampler (7): This depth

sampler (see Figure Il-A-7) has been used with-

out sterilization to collect bacteriological

water samples in high pollution areas. The

sampler consists of a cylindrical brass or plas-

tic tube (F) that contains a rubber stopper or

valve at either end (D and G). The valves are

connected to a rod (E) that passes through the

center of the cylinder. The device is lowered

into the water in the open position, and a water

sample is trapped in the cylinder when the

valves are closed by a dropped messenger (B).

The Kemmerer sampler should not be used for

collecting bacteriological samples without ob-

taining data that support its use without

sterilization.

2.6 Sediment Sampling with Van

Donsel-Geldreich Sampler (8): This device

(see Figure I1-A-8J collects sediment or mud in

sterile "Whlrl-Pak" plastic bags (A) down to 60

foot depth. The bag mouth is wrapped over

a nosepiece (B), and the bag is kept closed

during descent to the bottom by a bag clamp

bar (H). As the mud plate (D) contacts the bot-

tom, the nosepiece (B) is driven into the sedi-

ment by the weight (C) of the sampler. As the

nosepiece (B) moves downward, the bag (A)

slides through the bag clamp bar (H), opens,

and fills with sediment. The bag is sealed when

the double noose (F) tied to the bottom of the

bag is pulled, before the apparatus is returned

to the surface.

2.7 Water Tap Sampling: Make certain

that samples are not collected from spigots

that leak around their stems, or from spigots

that contain aeration devices or screens within

the faucet. For samples taken from direct water

main connections, the spigot should be flushed

for 2-3 minutes to clear the service line. For

wells equipped with hand or mechanical

pumps, pump the water to waste for five min-

utes before the sample is collected. Remove

the cap aseptically from the sample bottle. Hold

the sample bottle upright near the base while it

is being filled. Avoid splashing. Do not rinse the

bottle with the sample; fill it directly to within

2.5 cm (1 inch) from the top. Replace bottle

closure and hood covering. Caution must be

used to prevent contaminating the sample with

finger, gloves or other materials. If the well

does not have pumping machinery, collect the

sample using a weighted sterilized sample

bottle, such as described in 2.4 above, and

shown in Figure ll-A-3. Care must be taken to

avoid contaminating the sample with the sur-

face scum from the water surface.

2.8 Soil Sampling

2.8.1 Selection of the sampling site is

based on knowledge of the area and the pur-

poses of the analyses, i.e., surface sampling for

natural background, surface contamination, or

below surface sampling to monitor treatment

effect such as irrigation, or stormwater runoff.

The actual sites for sampling and the num-

ber of points to be sampled must be predeter-

mined by the survey objectives. Soil sampling

has the advantage of permitting the survey

planners to lay out a stable grid network for

sampling and resampling over a given time

period.

2.8.2 If a surface sample is desired, scrape

the top one inch of soil from a square foot area

using a sterile scoop or spoon.

If a subsurface sample is desired, use a

sterile scoop or spatula to remove the top

surface of one inch or more from a one foot

square area. Use a second sterile scoop or

spoon to take the sample.

Place samplings in a sterile one quart

screw-cap bottle until it is full. Depending on

the amount of moisture, a one quart bottle

holds 300-800 grams of soil. Label and tag

the bottle carefully and store at 4 C until

analyzed.

3. Sample Identification and Handling

3.1 Specific details on sample identifica-

tion are entered on a permanent label. Take

care in transcribing sampling information to

the label, because the enforcement action may

depend upon evidence of primary labeling.

See 4. in This Section. Labels must be clean.

14

&EPA MICROBIOLOGICAL MANUAL 1978

image:

2«5-4 Kemmerer Sampler (7): This depth

sampler (see Figure Il-A-7) has been used with-

out sterilization to collect bacteriological

water samples in high pollution areas. The

sampler consists of a cylindrical brass or plas-

tic tube (F) that contains a rubber stopper or

valve at either end (D and G). The valves are