<pubnumber>600278086</pubnumber>

<title>At-sea incineration of herbicide orange onboard the M/T Vulcanus</title>

<pages>274</pages>

<pubyear>1978</pubyear>

<provider>NEPIS</provider>

<access>online</access>

<origin>hardcopy</origin>

<author></author>

<publisher></publisher>

<subject></subject>

<abstract></abstract>

<operator>LM</operator>

<scandate>20120914</scandate>

<type>single page tiff</type>

<keyword></keyword>

EPA-600/2-78-086

April 1978

Environmental Protection Technology Series

AT-SEA INCINERATION

OF HERBICIDE ORANGE

ONBOARD THE M/T VULCANUS

Industrial Environmental Research Laboratory

Office of Research and Development

U.S. Environmental Protection Agency

Research Triangle Park, North Carolina 27711

image:

EPA-600/2-78-086

April 1978

AT-SEA INCINERATION

OF HERBICIDE ORANGE

ONBOARD THE M/T VULCANUS

by

D.G. Ackerman, H.J. Fisher, R.J. Johnson,

R.F. Maddalone, B.J. Matthews, E.L. Moon,

K.H. Scheyer, C.C. Shih, and R.F. Tobias

TRW, Inc.

One Space Park

Redondo Beach, California 90278

Contract No. 68-01-2966

Program Element No. 1AB604

EPA Project Officer: Ronald A. Venezia

U.S. Air Force Project Officer: James W. Tremblay

Industrial Environmental Research Laboratory

Ullice of tnergy, Minerals, HIK! Industry

Research Triangle Park, NC 27711

Prepared for

U.S. AIR FORCE U.S. ENVIRONMENTAL PROTECTION AGENCY

OEHL/EC and Office of Research and Development

Brooks Air Force Base, Texas 78235 Washington, D.C. 20460

image:

EPA-600/2-78-086

April 1978

AT-SEA INCINERATION

OF HERBICIDE ORANGE

ONBOARD THE M/T VULCANUS

by

D.G. Ackerman, H.J. Fisher, R.J. Johnson,

R.F. Maddalone, B.J. Matthews, E.L. Moon,

K.H. Scheyer, C.C. Shih, and R.F. Tobias

TRW, Inc.

One Space Park

Redondo Beach, California 90278

Contract No. 68-01-2966

Program Element No. 1AB604

EPA Project Officer: Ronald A. Venezia

U.S. Air Force Project Officer: James W. Tremblay

Industrial Environmental Research Laboratory

Ullice of tnergy, Minerals, HIK! Industry

Research Triangle Park, NC 27711

Prepared for

U.S. AIR FORCE U.S. ENVIRONMENTAL PROTECTION AGENCY

OEHL/EC and Office of Research and Development

Brooks Air Force Base, Texas 78235 Washington, D.C. 20460

image:

ABSTRACT

This report describes at-sea incineration of approximately 10,400 metric

tons of U.S. Air Force-owned Herbicide Orange onboard the incinerator ship

M/T Vulcanus. Incineration took place within a Pacific Ocean burn zone located

West of Johnston Atoll which was designated by the U.S. Environmental Protec-

tion Agency. Three shiploads of Herbicide Orange were incinerated. The first

shipload was transported from the U.S. Naval Construction Battalion Base at

Gulfport, Mississippi, to the burn zone and incinerated under provisions of

U.S. EPA Research Permit No. 770DH001R. Shiploads two and three were subse-

quently taken onboard the Vulcanus at Johnston Island and incinerated under

U.S. EPA Special Permit No. 770DH001S. The U.S. Air Force and Ocean Combus-

tion Services, B.V., The Netherlands (owner of the M/T Vulcanus), were the

permi ttees.

Monitoring, sampling, and analysis of the incineration process to assure

compliance with U.S. EPA permit operating and safety conditions related to

at-sea operations were performed by personnel of TRW, Inc., Redondo Beach,

California. A U.S. EPA representative was onboard the Vulcanus during the

Research Permit burn. A U.S. Air Force representative participated in the

monitoring team activities during all three burns.

Monitoring activities utilized on-line instrumentation to measure carbon

monoxide and dioxide, oxygen concentration, and total hydrocarbons from both

incinerators. These parameters served as a measure of overall combustion effi-

ciency with primary emphasis on the ratio of carbon dioxide to carbon monoxide

in the effluent gases. Combustion efficiency exceeded 99.9% during all three

burns. Herbicide Orange was injected into the incineration system at an aver-

age rate of 14.5 metric tons per hour. Optical pyrometer flame temperature

measurements averaged 1500°C. A dwell time of 1.0 second was calculated for

the combustion gases in the incinerators.

image:

ABSTRACT

This report describes at-sea incineration of approximately 10,400 metric

tons of U.S. Air Force-owned Herbicide Orange onboard the incinerator ship

M/T Vulcanus. Incineration took place within a Pacific Ocean burn zone located

West of Johnston Atoll which was designated by the U.S. Environmental Protec-

tion Agency. Three shiploads of Herbicide Orange were incinerated. The first

shipload was transported from the U.S. Naval Construction Battalion Base at

Gulfport, Mississippi, to the burn zone and incinerated under provisions of

U.S. EPA Research Permit No. 770DH001R. Shiploads two and three were subse-

quently taken onboard the Vulcanus at Johnston Island and incinerated under

U.S. EPA Special Permit No. 770DH001S. The U.S. Air Force and Ocean Combus-

tion Services, B.V., The Netherlands (owner of the M/T Vulcanus), were the

permi ttees.

Monitoring, sampling, and analysis of the incineration process to assure

compliance with U.S. EPA permit operating and safety conditions related to

at-sea operations were performed by personnel of TRW, Inc., Redondo Beach,

California. A U.S. EPA representative was onboard the Vulcanus during the

Research Permit burn. A U.S. Air Force representative participated in the

monitoring team activities during all three burns.

Monitoring activities utilized on-line instrumentation to measure carbon

monoxide and dioxide, oxygen concentration, and total hydrocarbons from both

incinerators. These parameters served as a measure of overall combustion effi-

ciency with primary emphasis on the ratio of carbon dioxide to carbon monoxide

in the effluent gases. Combustion efficiency exceeded 99.9% during all three

burns. Herbicide Orange was injected into the incineration system at an aver-

age rate of 14.5 metric tons per hour. Optical pyrometer flame temperature

measurements averaged 1500°C. A dwell time of 1.0 second was calculated for

the combustion gases in the incinerators.

image:

Effluent sampling was accomplished using a traversing sample probe

installed on the starboard incinerator. A USAF benzene impinger train and a

modified EPA Method 5 train were used to acquire combustion effluent samples.

Analysis of these samples was conducted to determine destruction efficiencies

for the normal butyl esters of 2,4-dichlorophenoxyacetic acid and 2,4,5 tri-

chlorophenoxyacetic acid, primary constituents of Herbicide Orange, as well as

2,3,7,8 tetrachlorodibenzo-p-dioxin, a contaminant present in the herbicide.

Destruction efficiencies in excess of 99.9% were determined for all three

burns.

Destruction and combustion efficiencies measured during the Research and

Special Permit burns met or exceeded requirements. All other conditions of

the permits related to at-sea incineration operations were met including adher-

ence to a comprehensive safety plan.

This report was submitted in fulfillment of Contract No. 68-01-2966 by

TRW Defense and Space Systems Group, TRW Inc., under sponsorship of the U.S.

Environmental Protection Agency. This report covers the period 15 April 1977

to 15 April 1978.

m

image:

Effluent sampling was accomplished using a traversing sample probe

installed on the starboard incinerator. A USAF benzene impinger train and a

modified EPA Method 5 train were used to acquire combustion effluent samples.

Analysis of these samples was conducted to determine destruction efficiencies

for the normal butyl esters of 2,4-dichlorophenoxyacetic acid and 2,4,5 tri-

chlorophenoxyacetic acid, primary constituents of Herbicide Orange, as well as

2,3,7,8 tetrachlorodibenzo-p-dioxin, a contaminant present in the herbicide.

Destruction efficiencies in excess of 99.9% were determined for all three

burns.

Destruction and combustion efficiencies measured during the Research and

Special Permit burns met or exceeded requirements. All other conditions of

the permits related to at-sea incineration operations were met including adher-

ence to a comprehensive safety plan.

This report was submitted in fulfillment of Contract No. 68-01-2966 by

TRW Defense and Space Systems Group, TRW Inc., under sponsorship of the U.S.

Environmental Protection Agency. This report covers the period 15 April 1977

to 15 April 1978.

m

image:

ACKNOWLEDGEMENTS

This effort was successfully accomplished because of the assistance and

cooperation of a large number of individuals and their respective organizations.

Equipment design and development, definition of sampling requirements, the

acquisition of samples and their subsequent analyses were accomplished by per-

sonnel from the Applied Technology and Environmental Engineering Divisions of

TRW, Inc., Redondo Beach, California. Analyses of certain types of samples

were performed by the Brehm Laboratory of Wright State University, Dayton, Ohio;

by Battelle-Columbus Laboratories, Columbus, Ohio; and by U.S. Air Force Occupa-

tional and Environmental Health Laboratories, Kelly and Brooks Air Force Bases,

Texas. Engineering liaison to adapt test equipment for use onboard the M/T

Vulcanus was facilitated by the management of Ocean Combustion Services, B.V.,

of The Netherlands. Installation of this equipment, as well as the acquisition

of data and samples, was accomplished through the assistance of the ship's

officers and crew. Complete cooperation was received from Johnston Island per-

sonnel of Holmes and Narver, Inc., Anaheim, California.

Technical direction, assistance, and planning of the conceptual design and

implementation of this program were received from a number of agencies and orga-

nizations within the U.S. Government. These include the U.S. Environmental Pro-

tection Agency's Oil and Special Materials Control Division (OSMCD), Washington,

D.C., Industrial Environmental Research Laboratory (IERL), Research Triangle

Park, North Carolina, and the Regional Office, Region IX, San Francisco,

California; the U.S. Air Force's Occupational and Environmental Health Labora-

tories (OEHL), Kelly and Brooks Air Force Bases, Texas, and McClellan Air Force

Base, California; the Air Force Logistics Command, Wright-Patterson Air Force

Base, Dayton, Ohio; the Military Sealift Command; the Military Airlift Command;

and the Defense Nuclear Agency. The Honolulu, Hawaii, Communications Station

of the U.S. Coast Guard provided communications between the M/T Vulcanus and

Johnston Island. U.S. Coast Guard Headquarters, Washington, D.C., provided

guidance in installation of equipment on the Vulcanus to conform with U.S. mari-

time regulations.

The authors are indebted to the many individuals of all of these organiza-

tions for their contributions.

iv

image:

ACKNOWLEDGEMENTS

This effort was successfully accomplished because of the assistance and

cooperation of a large number of individuals and their respective organizations.

Equipment design and development, definition of sampling requirements, the

acquisition of samples and their subsequent analyses were accomplished by per-

sonnel from the Applied Technology and Environmental Engineering Divisions of

TRW, Inc., Redondo Beach, California. Analyses of certain types of samples

were performed by the Brehm Laboratory of Wright State University, Dayton, Ohio;

by Battelle-Columbus Laboratories, Columbus, Ohio; and by U.S. Air Force Occupa-

tional and Environmental Health Laboratories, Kelly and Brooks Air Force Bases,

Texas. Engineering liaison to adapt test equipment for use onboard the M/T

Vulcanus was facilitated by the management of Ocean Combustion Services, B.V.,

of The Netherlands. Installation of this equipment, as well as the acquisition

of data and samples, was accomplished through the assistance of the ship's

officers and crew. Complete cooperation was received from Johnston Island per-

sonnel of Holmes and Narver, Inc., Anaheim, California.

Technical direction, assistance, and planning of the conceptual design and

implementation of this program were received from a number of agencies and orga-

nizations within the U.S. Government. These include the U.S. Environmental Pro-

tection Agency's Oil and Special Materials Control Division (OSMCD), Washington,

D.C., Industrial Environmental Research Laboratory (IERL), Research Triangle

Park, North Carolina, and the Regional Office, Region IX, San Francisco,

California; the U.S. Air Force's Occupational and Environmental Health Labora-

tories (OEHL), Kelly and Brooks Air Force Bases, Texas, and McClellan Air Force

Base, California; the Air Force Logistics Command, Wright-Patterson Air Force

Base, Dayton, Ohio; the Military Sealift Command; the Military Airlift Command;

and the Defense Nuclear Agency. The Honolulu, Hawaii, Communications Station

of the U.S. Coast Guard provided communications between the M/T Vulcanus and

Johnston Island. U.S. Coast Guard Headquarters, Washington, D.C., provided

guidance in installation of equipment on the Vulcanus to conform with U.S. mari-

time regulations.

The authors are indebted to the many individuals of all of these organiza-

tions for their contributions.

iv

image:

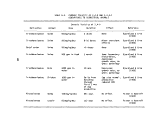

CONTENTS

Abstract li

Acknowledgements iv

Figures vii

Tables iriii

1. INTRODUCTION, BACKGROUND, AND SUMMARY 1

1.1 Introduction 1

1.2 Background 2

1.3 Summary 5

2. DESCRIPTION OF THE M/T VULCANUS 10

2.1 General Layout of Vessel 10

2.2 Tanks and Pumps 12

2.3 Incinerator System 13

2.4 Recording and Control Equipment 15

3. TEST OPERATIONS 18

3.1 Sampling and Monitoring Equipment and Procedures 18

3.2 Test Commentary and Problems 31

3.3 Marine Monitoring 36

3.4 Other Samples and Measurements 36

3.5 Combustion Effluent Samples Acquired 38

3.6 Sample Nomenclature 40

3.7 Waste Description 40

4. TEST RESULTS 48

4.1 Operational and Field Data 48

4.2 Analytical Results 59

4.3 Discussion of On-Line Instrumentation 93

5. SAFETY AND PERSONNEL PROTECTION 102

5.1 Design of the Personnel Protection Plan 103

5.2 Implementation of the Personnel Protection Plan 105

5.3 Results 106

5.4 Plume Characteristics and Control 108

5.5 Incidents 110

5.6 Summary of Ship Cleanliness Maintenance 116

6. WASTE DESTRUCTION EFFICIENCIES AND EMISSIONS ASSESSMENT 117

6.1 Waste Destruction Efficiencies 117

6.2 Emissions Assessment 120

7. ERROR PROPAGATION ANALYSIS OF DESTRUCTION EFFICIENCY

CALCULATIONS 126

REFERENCES 128

image:

CONTENTS

Abstract li

Acknowledgements iv

Figures vii

Tables iriii

1. INTRODUCTION, BACKGROUND, AND SUMMARY 1

1.1 Introduction 1

1.2 Background 2

1.3 Summary 5

2. DESCRIPTION OF THE M/T VULCANUS 10

2.1 General Layout of Vessel 10

2.2 Tanks and Pumps 12

2.3 Incinerator System 13

2.4 Recording and Control Equipment 15

3. TEST OPERATIONS 18

3.1 Sampling and Monitoring Equipment and Procedures 18

3.2 Test Commentary and Problems 31

3.3 Marine Monitoring 36

3.4 Other Samples and Measurements 36

3.5 Combustion Effluent Samples Acquired 38

3.6 Sample Nomenclature 40

3.7 Waste Description 40

4. TEST RESULTS 48

4.1 Operational and Field Data 48

4.2 Analytical Results 59

4.3 Discussion of On-Line Instrumentation 93

5. SAFETY AND PERSONNEL PROTECTION 102

5.1 Design of the Personnel Protection Plan 103

5.2 Implementation of the Personnel Protection Plan 105

5.3 Results 106

5.4 Plume Characteristics and Control 108

5.5 Incidents 110

5.6 Summary of Ship Cleanliness Maintenance 116

6. WASTE DESTRUCTION EFFICIENCIES AND EMISSIONS ASSESSMENT 117

6.1 Waste Destruction Efficiencies 117

6.2 Emissions Assessment 120

7. ERROR PROPAGATION ANALYSIS OF DESTRUCTION EFFICIENCY

CALCULATIONS 126

REFERENCES 128

image:

CONTENTS (Continued)

APPENDICES 129

A. Safety Plan for Incineration of Herbicide Orange

Onboard the M/T Vulcanus 129

B. Toxicological Properties of 2,4-D, 2,4,5-T and TCDD 155

C. Analytical Procedures Used by TRW 182

D. Thermochemical Analysis and Estimation of

Emission Levels 218

E. Trapping Efficiency Study of the Lear-Siegler

Train Sorbent Trap 230

F. Sample Calculations 236

G. Analysis of Variance of Destruction

Efficiency Calculations 248

image:

CONTENTS (Continued)

APPENDICES 129

A. Safety Plan for Incineration of Herbicide Orange

Onboard the M/T Vulcanus 129

B. Toxicological Properties of 2,4-D, 2,4,5-T and TCDD 155

C. Analytical Procedures Used by TRW 182

D. Thermochemical Analysis and Estimation of

Emission Levels 218

E. Trapping Efficiency Study of the Lear-Siegler

Train Sorbent Trap 230

F. Sample Calculations 236

G. Analysis of Variance of Destruction

Efficiency Calculations 248

image:

FIGURES

Number Page

1 Geographical relationship of burn zone to Johnston

Atoll and the Hawaiian Islands 6

2 M/T Vulcanus — incineration vessel 10

3 Cargo tank layout schematic 12

4 Incinerator configuration 13

5 Incineration system — burner and thermocouple locations ... 14

6 Layout of portable laboratory 21

7 Configuration of heat traced lines, probes, and

sampling trains 22

8 Schematic of on-line monitoring system 23

9 Probe design 25

10 Schematic of mount for the movable probe 25

11 Sampling port locations 27

12 Traverse points for stack sampling 27

13 Schematic of USAF-OEHL benzene impinger sampling train .... 28

14 Schematic of Lear-Siegler stack sampling train 29

15 Combustion efficiency versus probe insertion depth 52

16 Flow diagram of TRW analysis plan 61

17 Location of wipe samples on M/T Vulcanus — summary

of three burns 97

18 Ship headings relative to wind direction which avoided

plume impact on ship 110

19 Schematic of Vulcanus1 main deck showing

spill locations 113

vii

image:

FIGURES

Number Page

1 Geographical relationship of burn zone to Johnston

Atoll and the Hawaiian Islands 6

2 M/T Vulcanus — incineration vessel 10

3 Cargo tank layout schematic 12

4 Incinerator configuration 13

5 Incineration system — burner and thermocouple locations ... 14

6 Layout of portable laboratory 21

7 Configuration of heat traced lines, probes, and

sampling trains 22

8 Schematic of on-line monitoring system 23

9 Probe design 25

10 Schematic of mount for the movable probe 25

11 Sampling port locations 27

12 Traverse points for stack sampling 27

13 Schematic of USAF-OEHL benzene impinger sampling train .... 28

14 Schematic of Lear-Siegler stack sampling train 29

15 Combustion efficiency versus probe insertion depth 52

16 Flow diagram of TRW analysis plan 61

17 Location of wipe samples on M/T Vulcanus — summary

of three burns 97

18 Ship headings relative to wind direction which avoided

plume impact on ship 110

19 Schematic of Vulcanus1 main deck showing

spill locations 113

vii

image:

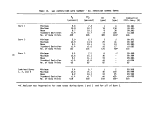

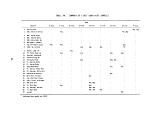

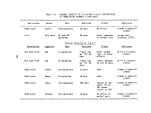

TABLES

Number Page

1 Definition of Incineration Efficiency Terms 7

2 Summary of Calculated Incineration Efficiencies 8

3 Specifications of the M/T Vulcanus 11

4 On-Line Monitors 23

5 Summary of Combustion Effluent Samples Acquired 39

6 Train Sample Volumes and Apportionment of Probe and

Line Rinses 41

7 Herbicide Orange Program Sample Labeling Scheme ........ 43

8 General Chemical and Physical Properties of

Herbicide Orange 44

9 General Properties of Ingredient Esters of

Herbicide Orange 45

10 General Data Relative to TCDD 45

11 Average Composition of Several Lots of

Herbicide Orange 46

12 Drums Authorized for Loading for Third Bum 47

13 Gas Composition Data - First Burn 49

14 Gas Composition Data - Second Burn 50

15 Gas Composition Data - Third Burn 51

16 Gas Composition Data Summary - All Herbicide

Orange Burns 53

17 Tank Burning Summary - First Burn 55

18 Tank Burning Summary - Second Burn 56

viii

image:

TABLES

Number Page

1 Definition of Incineration Efficiency Terms 7

2 Summary of Calculated Incineration Efficiencies 8

3 Specifications of the M/T Vulcanus 11

4 On-Line Monitors 23

5 Summary of Combustion Effluent Samples Acquired 39

6 Train Sample Volumes and Apportionment of Probe and

Line Rinses 41

7 Herbicide Orange Program Sample Labeling Scheme ........ 43

8 General Chemical and Physical Properties of

Herbicide Orange 44

9 General Properties of Ingredient Esters of

Herbicide Orange 45

10 General Data Relative to TCDD 45

11 Average Composition of Several Lots of

Herbicide Orange 46

12 Drums Authorized for Loading for Third Bum 47

13 Gas Composition Data - First Burn 49

14 Gas Composition Data - Second Burn 50

15 Gas Composition Data - Third Burn 51

16 Gas Composition Data Summary - All Herbicide

Orange Burns 53

17 Tank Burning Summary - First Burn 55

18 Tank Burning Summary - Second Burn 56

viii

image:

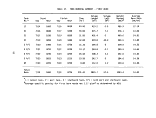

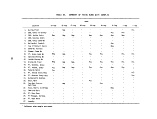

TABLES (Continued)

Number Page

19 Incinerator Temperatures - First Burn 57

20 Incinerator Temperatures - Second Burn 57

21 Incinerator Temperatures - Third Burn 58

22 Results of C7-C16 GC Analyses of Feedstocks 65

23 Results of GCMS Analyses of Feedstocks 66

24 Organic Contents of Lear-Siegler Train Samples

from Thermogravimetric Analyses 67

25 Results of Gravimetric Analyses of Lear-Siegler

Train Samples 68

26 Classes of Nonvolatile Organic Compounds Present

in Lear-Siegler Train Samples 69

27 Emissions of Volatile Organic Compounds from C7-C16

GC Analyses of Lear-Siegler Train Samples 70

28 Gravimetric Results of Liquid Chromatographic

Separations of Lear-Siegler Train Samples 72

29 Compound Classes Present in LC Fractions from

Lear-Siegler Train Samples 73

30 GC/MS Analyses of Lear-Siegler Train Samples 75

31 Results of C1-C6 Analyses of Grab Gas Samples 79

32 Organic Contents of Burner Residue Extracts from

Thermogravimetric Analyses 80

33 Results of Gravimetric Analyses of Burner Residue

Samples 80

34 Results of C7-C16 GC Analyses of Burner

Residue Samples 81

35 Gravimetric Results of LC Separations of

Burner Residues 82

36 Compound Classes Present in LC Fractions from

Burner Residue Samples 83

ix

image:

TABLES (Continued)

Number Page

19 Incinerator Temperatures - First Burn 57

20 Incinerator Temperatures - Second Burn 57

21 Incinerator Temperatures - Third Burn 58

22 Results of C7-C16 GC Analyses of Feedstocks 65

23 Results of GCMS Analyses of Feedstocks 66

24 Organic Contents of Lear-Siegler Train Samples

from Thermogravimetric Analyses 67

25 Results of Gravimetric Analyses of Lear-Siegler

Train Samples 68

26 Classes of Nonvolatile Organic Compounds Present

in Lear-Siegler Train Samples 69

27 Emissions of Volatile Organic Compounds from C7-C16

GC Analyses of Lear-Siegler Train Samples 70

28 Gravimetric Results of Liquid Chromatographic

Separations of Lear-Siegler Train Samples 72

29 Compound Classes Present in LC Fractions from

Lear-Siegler Train Samples 73

30 GC/MS Analyses of Lear-Siegler Train Samples 75

31 Results of C1-C6 Analyses of Grab Gas Samples 79

32 Organic Contents of Burner Residue Extracts from

Thermogravimetric Analyses 80

33 Results of Gravimetric Analyses of Burner Residue

Samples 80

34 Results of C7-C16 GC Analyses of Burner

Residue Samples 81

35 Gravimetric Results of LC Separations of

Burner Residues 82

36 Compound Classes Present in LC Fractions from

Burner Residue Samples 83

ix

image:

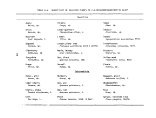

TABLES (Continued)

Number Page

37 Results of GC/MS Analyses of Burner Residue Samples 84

38 Results of WSU Analyses of Stack Samples for TCDD 85

39 Results of BCL Analyses of First Burn Workspace

Air Monitors 87

40 Results of BCL Analyses of Second and Third Burn

Workspace Air Monitors 88

41 Results of BCL Analyses of Combustion Effluent Samples .... 89

42 Results of BCL Analyses of Ship's Drinking Water

for 2,4-D and 2,4,5-T 90

43 Summary of Pre- and Post-Loading Wipe Samples 92

44 Summary of First Burn Wipe Samples 94

45 Summary of Second Burn Wipe Samples 95

46 Summary of Third Burn Wipe Samples 96

47 Comparison of Combustion and Destruction Efficiencies .... 99

48 Hydrogen Chloride (HC1) in Air Onboard M/T Vulcanus 109

49 Emission Concentrations of 2,4-D + 2,4,5-T and TCDD at

0% Destruction Efficiency 118

50 Destruction Efficiencies for TCDD from WSU Analyses 120

51 Destruction Efficiencies for 2,4-D and 2,4,5-T from

Lear-Siegler Train Analyses 121

52 Destruction Efficiencies for 2,4-D and 2,4,5-T from

BCL Analyses 122

53 Destruction Efficiencies of Organochlorine Compounds 123

54 Estimates of Volatile Hydrocarbon Emissions 124

55 Estimates of Emissions of Aromatic Hydrocarbons 125

56 Summary of Variables for Error Analysis 127

image:

TABLES (Continued)

Number Page

37 Results of GC/MS Analyses of Burner Residue Samples 84

38 Results of WSU Analyses of Stack Samples for TCDD 85

39 Results of BCL Analyses of First Burn Workspace

Air Monitors 87

40 Results of BCL Analyses of Second and Third Burn

Workspace Air Monitors 88

41 Results of BCL Analyses of Combustion Effluent Samples .... 89

42 Results of BCL Analyses of Ship's Drinking Water

for 2,4-D and 2,4,5-T 90

43 Summary of Pre- and Post-Loading Wipe Samples 92

44 Summary of First Burn Wipe Samples 94

45 Summary of Second Burn Wipe Samples 95

46 Summary of Third Burn Wipe Samples 96

47 Comparison of Combustion and Destruction Efficiencies .... 99

48 Hydrogen Chloride (HC1) in Air Onboard M/T Vulcanus 109

49 Emission Concentrations of 2,4-D + 2,4,5-T and TCDD at

0% Destruction Efficiency 118

50 Destruction Efficiencies for TCDD from WSU Analyses 120

51 Destruction Efficiencies for 2,4-D and 2,4,5-T from

Lear-Siegler Train Analyses 121

52 Destruction Efficiencies for 2,4-D and 2,4,5-T from

BCL Analyses 122

53 Destruction Efficiencies of Organochlorine Compounds 123

54 Estimates of Volatile Hydrocarbon Emissions 124

55 Estimates of Emissions of Aromatic Hydrocarbons 125

56 Summary of Variables for Error Analysis 127

image:

1. INTRODUCTION, BACKGROUND, AND SUMMARY

1.1 INTRODUCTION

Thermal destruction of combustible wastes at sea is recognized as an alter-

native to land based incineration. In late 1974 and in March of 1977, organo-

chlorine wastes were incinerated in the Gulf of Mexico by the Motor Tanker (M/T)

Vulcanus. These efforts, evaluated by the U.S. Environmental Protection Agency

(U.S. EPA), provided a technical basis for concluding that at-sea incineration

is a viable alternative to other means of disposal.

Incineration of U.S. Air Force stocks of Herbicide Orange was performed

onboard the M/T Vulcanus operating in the Pacific Ocean west of Johnston Atoll.

Approximately 10,400 metric tons were incinerated under permits granted by the

U.S. EPA. The first shipload, loaded at the Naval Construction Battalion Cen-

ter at Gulfport, Mississippi, was incinerated under Research Permit No. 770DH001R.

The second and third shiploads, loaded at Johnston Island (one of the islands

comprising Johnston Atoll), were incinerated under Special Permit No. 770DH001S.

The Herbicide Orange incinerated consisted of an approximate 50-50 mixture

by volume of the n-butyl esters of 2,4-dichlorophenoxyacetic acid (2,4-D) and

2,4,5-trichlorophenoxyacetic acid (2,4,5-Tr . There was a small quantity of

Orange II herbicide which consisted of an approximate 50-50 mixture by volume of

2,4-D and the iso-octyl ester of 2,4,5-trichlorophenoxyacetic acid^ '. Certain

lots of the herbicide contained the contaminant 2,3,7,8-tetrachlorodibenzo-p-

dioxin (TCDD). The TCDD concentration in the entire stock of herbicide averaged

1.9 ppm and ranged from 0 to 47 ppnr . Diesel fuel used to rinse herbicide

drums and equipment associated with dedrumming and loading was mixed with the

herbicide for incineration.

1. From U.S. EPA Special Permit No. 770DH001S.

image:

1. INTRODUCTION, BACKGROUND, AND SUMMARY

1.1 INTRODUCTION

Thermal destruction of combustible wastes at sea is recognized as an alter-

native to land based incineration. In late 1974 and in March of 1977, organo-

chlorine wastes were incinerated in the Gulf of Mexico by the Motor Tanker (M/T)

Vulcanus. These efforts, evaluated by the U.S. Environmental Protection Agency

(U.S. EPA), provided a technical basis for concluding that at-sea incineration

is a viable alternative to other means of disposal.

Incineration of U.S. Air Force stocks of Herbicide Orange was performed

onboard the M/T Vulcanus operating in the Pacific Ocean west of Johnston Atoll.

Approximately 10,400 metric tons were incinerated under permits granted by the

U.S. EPA. The first shipload, loaded at the Naval Construction Battalion Cen-

ter at Gulfport, Mississippi, was incinerated under Research Permit No. 770DH001R.

The second and third shiploads, loaded at Johnston Island (one of the islands

comprising Johnston Atoll), were incinerated under Special Permit No. 770DH001S.

The Herbicide Orange incinerated consisted of an approximate 50-50 mixture

by volume of the n-butyl esters of 2,4-dichlorophenoxyacetic acid (2,4-D) and

2,4,5-trichlorophenoxyacetic acid (2,4,5-Tr . There was a small quantity of

Orange II herbicide which consisted of an approximate 50-50 mixture by volume of

2,4-D and the iso-octyl ester of 2,4,5-trichlorophenoxyacetic acid^ '. Certain

lots of the herbicide contained the contaminant 2,3,7,8-tetrachlorodibenzo-p-

dioxin (TCDD). The TCDD concentration in the entire stock of herbicide averaged

1.9 ppm and ranged from 0 to 47 ppnr . Diesel fuel used to rinse herbicide

drums and equipment associated with dedrumming and loading was mixed with the

herbicide for incineration.

1. From U.S. EPA Special Permit No. 770DH001S.

image:

1.2 BACKGROUND

The at-sea incineration of U.S. Air Force stocks of Herbicide Orange was a

complex undertaking. A large number of U.S. Government organizations and civil-

ian contractors contributed to the effort, and a brief discussion of the program

organization will be helpful in understanding the scope of this report.

Permits to incinerate the waste were granted to the U.S. Air Force, owner

of the waste, and to Ocean Combustion Services, B.V., of The Netherlands, owner

of the M/T Vulcanus, as co-permittees.

The U.S. EPA contracted with TRW, Inc., to perform environmental monitoring

during the incineration of the herbicide. This program was funded by the U.S.

Air Force. The scope of TRW's activities under this contract included design

and preparation of stack sampling and monitoring equipment, development of a

comprehensive personnel protection plan, development and implementation of a

sampling and analysis protocol, acquisition of samples and monitoring of combus-

tion effluent during incinerator operation, analysis of the samples and moni-

toring data, and evaluation of the results.

TRW's role in the incineration program was thus limited to at-sea opera-

tions. It was TRW's responsibility to monitor the following permit conditions

(renumbered but verbatim from Reference 1):

1. The Permittees are authorized to heat up incinerators with fuel

oil while in route to the site but may not incinerate the des-

cribed wastes except in the site which is defined in longitude

and latitude as follows: From 15 degrees 45 minutes to 17 degrees

45 minutes north latitude. From 171 degrees 30 minutes to

173 degrees 30 minutes west longitude.

2. During start-up, Herbicide Orange shall not be fed into the

incinerators until a flame temperature of 1280°C has been

reached in the furnace and only one burner at a time shall

be changed over to the waste. The start-up temperature of

1280°C must be reached before the next burner is changed

over to Herbicide Orange.

3. Monitoring of the furnaces for temperature, and for complete-

ness of combustion, shall be in effect during the change-over.

A record of temperature shall also be maintained during this

time.

4. The incinerator flame temperature shall be greater than

1250°C when burning waste.

image:

1.2 BACKGROUND

The at-sea incineration of U.S. Air Force stocks of Herbicide Orange was a

complex undertaking. A large number of U.S. Government organizations and civil-

ian contractors contributed to the effort, and a brief discussion of the program

organization will be helpful in understanding the scope of this report.

Permits to incinerate the waste were granted to the U.S. Air Force, owner

of the waste, and to Ocean Combustion Services, B.V., of The Netherlands, owner

of the M/T Vulcanus, as co-permittees.

The U.S. EPA contracted with TRW, Inc., to perform environmental monitoring

during the incineration of the herbicide. This program was funded by the U.S.

Air Force. The scope of TRW's activities under this contract included design

and preparation of stack sampling and monitoring equipment, development of a

comprehensive personnel protection plan, development and implementation of a

sampling and analysis protocol, acquisition of samples and monitoring of combus-

tion effluent during incinerator operation, analysis of the samples and moni-

toring data, and evaluation of the results.

TRW's role in the incineration program was thus limited to at-sea opera-

tions. It was TRW's responsibility to monitor the following permit conditions

(renumbered but verbatim from Reference 1):

1. The Permittees are authorized to heat up incinerators with fuel

oil while in route to the site but may not incinerate the des-

cribed wastes except in the site which is defined in longitude

and latitude as follows: From 15 degrees 45 minutes to 17 degrees

45 minutes north latitude. From 171 degrees 30 minutes to

173 degrees 30 minutes west longitude.

2. During start-up, Herbicide Orange shall not be fed into the

incinerators until a flame temperature of 1280°C has been

reached in the furnace and only one burner at a time shall

be changed over to the waste. The start-up temperature of

1280°C must be reached before the next burner is changed

over to Herbicide Orange.

3. Monitoring of the furnaces for temperature, and for complete-

ness of combustion, shall be in effect during the change-over.

A record of temperature shall also be maintained during this

time.

4. The incinerator flame temperature shall be greater than

1250°C when burning waste.

image:

5. An automatic shut-off device shall be in operation on both

furnaces, set to turn off the flow of waste if the flame

temperature drops below 1250°C.

6. The Herbicide Orange feed rate to each incinerator shall not

exceed 11.5 tonnes/hour (11.5 metric tons/hour).

7. Incineration shall take place in the presence of excess air

such that there shall be a 3 mole percent minimum oxygen con-

tent in the combustion product gas.

8. The combustion efficiency of the incineration and destruction

efficiency of waste during the incineration will be at least

99.9 percent complete. If the efficiency level falls below

99.9 percent, the incinerators on the Vulcanus will be shut

down immediately until corrective measures which assure

99.9 percent combustion efficiency are applied.

9. The emission rates of TCDD, 2,4-D, or 2,4,5-T will not be in

excess of 0.1% of the total amounts of TCDD, 2,4-D or 2,4,5-T

in the Herbicide Orange waste. (Wright State University had

responsibility for analyses to determine emission rates of

(TCDD.)

10.a. An automatic sealed monitoring device (black box) will be

installed to record incineration activities and temperatures

and camera to photograph the control panel every 15 minutes.

10.b. A manual log shall be kept and the following information

recorded at 1-hour intervals:

a. Time, date

b. "Black box" temperature

c. Controller temperature reading

d. Waste feed rates

e. Switching of waste tanks

f. Wind speed and direction

g. Location

(For the third burn, this requirement was changed to 2-hour

intervals.)

11. A device for addition of ammonia to make a visible plume will

be installed.

12. Permittees shall ensure their position during transport and

within the discharge site at all times by on-board naviga-

tional aids, and shall maintain documentation of position.

image:

5. An automatic shut-off device shall be in operation on both

furnaces, set to turn off the flow of waste if the flame

temperature drops below 1250°C.

6. The Herbicide Orange feed rate to each incinerator shall not

exceed 11.5 tonnes/hour (11.5 metric tons/hour).

7. Incineration shall take place in the presence of excess air

such that there shall be a 3 mole percent minimum oxygen con-

tent in the combustion product gas.

8. The combustion efficiency of the incineration and destruction

efficiency of waste during the incineration will be at least

99.9 percent complete. If the efficiency level falls below

99.9 percent, the incinerators on the Vulcanus will be shut

down immediately until corrective measures which assure

99.9 percent combustion efficiency are applied.

9. The emission rates of TCDD, 2,4-D, or 2,4,5-T will not be in

excess of 0.1% of the total amounts of TCDD, 2,4-D or 2,4,5-T

in the Herbicide Orange waste. (Wright State University had

responsibility for analyses to determine emission rates of

(TCDD.)

10.a. An automatic sealed monitoring device (black box) will be

installed to record incineration activities and temperatures

and camera to photograph the control panel every 15 minutes.

10.b. A manual log shall be kept and the following information

recorded at 1-hour intervals:

a. Time, date

b. "Black box" temperature

c. Controller temperature reading

d. Waste feed rates

e. Switching of waste tanks

f. Wind speed and direction

g. Location

(For the third burn, this requirement was changed to 2-hour

intervals.)

11. A device for addition of ammonia to make a visible plume will

be installed.

12. Permittees shall ensure their position during transport and

within the discharge site at all times by on-board naviga-

tional aids, and shall maintain documentation of position.

image:

13. Permittees shall have installed and in operating condition a

radio or other communications devices which are capable of

voice transmission to the mainland from the Vulcanus when in

route to the incineration site and during the incineration of

the waste in the designated site. The frequency of reporting

and information to be transmitted is set forth in the Herbicide

Orange Contingency Plan contained in Appendix 9 of the hearing

record of April 7, 1977.

14. During the burns the Permittees shall transmit the following

information to EPA Headquarters every 24 hours:

a. Operating temperatures

b. Average combustion efficiency

c. Significant malfunctions/incidents

15. The Permittees shall monitor for carbon monoxide, carbon diox-

ide, oxygen, 2,4-D, 2,4,5-T, TCDD and other parameters in

accordance with the monitoring plan contained in Appendix B

(of the permit).

16. The Permittees shall comply with all provisions of the com-

prehensive safety plan set forth in Appendix C (of the permit).

During incineration of the first shipload, a U.S. EPA Representative was

onboard to determine compliance with permit conditions. During incineration

of the second and third shiploads, the leader of the TRW sampling team was

designated U.S. EPA Advisor relative to permit compliance.

The U.S. Air Force issued a contract (No. F41608-77-C-0169) to the Brehm

Laboratory of Wright State University (WSU) to perform analyses for the toxic

contaminant (2,3,7,8-tetrachlorodibenzo-p-dioxin, TCDD) in the combustion efflu-

ent samples taken onboard the ship during incineration. The analyses by Wright

State were intended to determine compliance with the permit requirement that

emissions of TCDD not exceed 0.1% of the total TCDD in the waste. In other

words, the destruction efficiency of TCDD was required to be not less than

99.9%.

The U.S. Air Force issued a contract (No. F08635-76-D-0168) to Battelle-

Columbus Laboratories (BCL) to perform land based environmental monitoring

(air, land, and water) during the dedrumming and loading operations at Johnston

Atoll. BCL also analyzed combustion effluent, potable water, and workspace

air monitor samples from the ship for 2,4-D and 2,4,5-T.

image:

13. Permittees shall have installed and in operating condition a

radio or other communications devices which are capable of

voice transmission to the mainland from the Vulcanus when in

route to the incineration site and during the incineration of

the waste in the designated site. The frequency of reporting

and information to be transmitted is set forth in the Herbicide

Orange Contingency Plan contained in Appendix 9 of the hearing

record of April 7, 1977.

14. During the burns the Permittees shall transmit the following

information to EPA Headquarters every 24 hours:

a. Operating temperatures

b. Average combustion efficiency

c. Significant malfunctions/incidents

15. The Permittees shall monitor for carbon monoxide, carbon diox-

ide, oxygen, 2,4-D, 2,4,5-T, TCDD and other parameters in

accordance with the monitoring plan contained in Appendix B

(of the permit).

16. The Permittees shall comply with all provisions of the com-

prehensive safety plan set forth in Appendix C (of the permit).

During incineration of the first shipload, a U.S. EPA Representative was

onboard to determine compliance with permit conditions. During incineration

of the second and third shiploads, the leader of the TRW sampling team was

designated U.S. EPA Advisor relative to permit compliance.

The U.S. Air Force issued a contract (No. F41608-77-C-0169) to the Brehm

Laboratory of Wright State University (WSU) to perform analyses for the toxic

contaminant (2,3,7,8-tetrachlorodibenzo-p-dioxin, TCDD) in the combustion efflu-

ent samples taken onboard the ship during incineration. The analyses by Wright

State were intended to determine compliance with the permit requirement that

emissions of TCDD not exceed 0.1% of the total TCDD in the waste. In other

words, the destruction efficiency of TCDD was required to be not less than

99.9%.

The U.S. Air Force issued a contract (No. F08635-76-D-0168) to Battelle-

Columbus Laboratories (BCL) to perform land based environmental monitoring

(air, land, and water) during the dedrumming and loading operations at Johnston

Atoll. BCL also analyzed combustion effluent, potable water, and workspace

air monitor samples from the ship for 2,4-D and 2,4,5-T.

image:

U.S. Air Force Occupational and Environmental Health Laboratories (OEHL)

at Kelly and Brooks Air Force Bases, Texas, analyzed miscellaneous samples from

both land based and at-sea operations. BCL and WSU analyzed a variety of sam-

ples intended to determine the effect of U.S. EPA approved ship cleaning proce-

dures after waste incineration had been completed. The TRW sampling team

leader had been designated by the U.S. EPA to monitor that portion of the ship

cleaning performed while the TRW team was still onboard the ship.

The final responsibility of TRW to the U.S. EPA was to prepare a final

report assembling and evaluating all data relating to incineration operations

so as to determine compliance with those permit conditions concerning at-sea

operations.

1.3 SUMMARY

Incineration of the herbicide took place in a U.S. EPA-designated burn

zone approximately 120 miles west of Johnston Atoll, as defined by the follow-

ing coordinates: 15°45' to 17°45' N latitude and 171°30' to 173°30' W longi-

tude. The relationship of the burn zone to Johnston Atoll and the Hawaiian

Islands is shown in Figure 1.

o

A total of 10,400 metric tons (8780 m , 2.31 million gallons) of waste was

burned, requiring 714 hours. The average incineration rate was 14.5 metric

tons per hour or 7.3 metric tons per hour per incinerator. For all three burns,

the average flame temperature was 1500°C as determined by daily optical pyrom-

eter measurements. The average incinerator wall temperature (controller

thermocouple) was 1273°C for all three burns. For the three burns, the average

combustion effluent flow rate per incinerator was calculated to be 70,700 cubic

meters per hour (dry gas at 20°C). Given these average conditions of combustion

air and waste feed rates and temperature, the average calculated incinerator

residence time was 1.0 second. The incinerator residence time was the time

available for a waste molecule to be converted to combustion products.

Stack sampling operations utilized a USAF-OEHL benzene impinger train and

a modified U.S. EPA Method 5 train (Lear-Siegler) which incorporated an organic

vapor sorbent trap. The USAF-OEHL train was the primary train for acquiring

samples for TCDD analysis, whereas the Lear-Siegler train was used to acquire

samples to be analyzed for organic species potentially present in the combustion

image:

U.S. Air Force Occupational and Environmental Health Laboratories (OEHL)

at Kelly and Brooks Air Force Bases, Texas, analyzed miscellaneous samples from

both land based and at-sea operations. BCL and WSU analyzed a variety of sam-

ples intended to determine the effect of U.S. EPA approved ship cleaning proce-

dures after waste incineration had been completed. The TRW sampling team

leader had been designated by the U.S. EPA to monitor that portion of the ship

cleaning performed while the TRW team was still onboard the ship.

The final responsibility of TRW to the U.S. EPA was to prepare a final

report assembling and evaluating all data relating to incineration operations

so as to determine compliance with those permit conditions concerning at-sea

operations.

1.3 SUMMARY

Incineration of the herbicide took place in a U.S. EPA-designated burn

zone approximately 120 miles west of Johnston Atoll, as defined by the follow-

ing coordinates: 15°45' to 17°45' N latitude and 171°30' to 173°30' W longi-

tude. The relationship of the burn zone to Johnston Atoll and the Hawaiian

Islands is shown in Figure 1.

o

A total of 10,400 metric tons (8780 m , 2.31 million gallons) of waste was

burned, requiring 714 hours. The average incineration rate was 14.5 metric

tons per hour or 7.3 metric tons per hour per incinerator. For all three burns,

the average flame temperature was 1500°C as determined by daily optical pyrom-

eter measurements. The average incinerator wall temperature (controller

thermocouple) was 1273°C for all three burns. For the three burns, the average

combustion effluent flow rate per incinerator was calculated to be 70,700 cubic

meters per hour (dry gas at 20°C). Given these average conditions of combustion

air and waste feed rates and temperature, the average calculated incinerator

residence time was 1.0 second. The incinerator residence time was the time

available for a waste molecule to be converted to combustion products.

Stack sampling operations utilized a USAF-OEHL benzene impinger train and

a modified U.S. EPA Method 5 train (Lear-Siegler) which incorporated an organic

vapor sorbent trap. The USAF-OEHL train was the primary train for acquiring

samples for TCDD analysis, whereas the Lear-Siegler train was used to acquire

samples to be analyzed for organic species potentially present in the combustion

image:

145°

150"

155°

160°

165°

170°

175"

180° 175° 170° 165° 160° 155°

25"

20°

15s

10°

0«

10°

15*

t

GUA

*',

'MARIA

fSAIPAr

iFTINIAf

fROTA

M

CAI

«IAS ISLAf

-1

g

OLINE IS

- -

-

IDS

Eh

AMDS

SOLOM

, -,

<

IWETOK 1

•

DN ISLAN

/AKE IS

.

•

(WAJALEI

DS

SAMO/

4 IS

N

•

IDWAY IS

B

HOWLA

•

•BA

FIJI ISL

JRNZOI>

MDIS

KERIS

,NDS

CH FRIG>

•

• JOHN!

TE SHOA

TON ATC

OAHU

' I

HAV

LL

• FANN

•

CHRISTM,

Ml

NG IS

kSIS

25°

20°

15°

10-

10-

IS-

MS' ISO* 15S" 160° 165° 170° 175° 180° 175° 170° 16S° 160° 153*

Figure 1. Geographical relationship of burn zone to

Johnston Atoll and the Hawaiian Islands.

effluent. The Lear-Siegler train also served as a backup to the USAF-OEHL train.

These stack samples were subsequently analyzed to determine how effectively the

incineration process destroyed constituents of the waste. Stack samples were

acquired by a remotely activated, water-cooled, stainless steel probe capable

of traversing the starboard stack diameter of 3.4 meters.

During stack sampling operations, incineration effluent products were

simultaneously monitored for total hydrocarbons, carbon monoxide, carbon diox-

ide, and oxygen. Concentrations of these species were measured in real time to

monitor the overall combustion efficiency of the incinerator. Instrumentation

for these measurements was housed in a modified shipping container lashed to

the ship's deck.

image:

145°

150"

155°

160°

165°

170°

175"

180° 175° 170° 165° 160° 155°

25"

20°

15s

10°

0«

10°

15*

t

GUA

*',

'MARIA

fSAIPAr

iFTINIAf

fROTA

M

CAI

«IAS ISLAf

-1

g

OLINE IS

- -

-

IDS

Eh

AMDS

SOLOM

, -,

<

IWETOK 1

•

DN ISLAN

/AKE IS

.

•

(WAJALEI

DS

SAMO/

4 IS

N

•

IDWAY IS

B

HOWLA

•

•BA

FIJI ISL

JRNZOI>

MDIS

KERIS

,NDS

CH FRIG>

•

• JOHN!

TE SHOA

TON ATC

OAHU

' I

HAV

LL

• FANN

•

CHRISTM,

Ml

NG IS

kSIS

25°

20°

15°

10-

10-

IS-

MS' ISO* 15S" 160° 165° 170° 175° 180° 175° 170° 16S° 160° 153*

Figure 1. Geographical relationship of burn zone to

Johnston Atoll and the Hawaiian Islands.

effluent. The Lear-Siegler train also served as a backup to the USAF-OEHL train.

These stack samples were subsequently analyzed to determine how effectively the

incineration process destroyed constituents of the waste. Stack samples were

acquired by a remotely activated, water-cooled, stainless steel probe capable

of traversing the starboard stack diameter of 3.4 meters.

During stack sampling operations, incineration effluent products were

simultaneously monitored for total hydrocarbons, carbon monoxide, carbon diox-

ide, and oxygen. Concentrations of these species were measured in real time to

monitor the overall combustion efficiency of the incinerator. Instrumentation

for these measurements was housed in a modified shipping container lashed to

the ship's deck.

image:

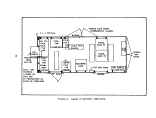

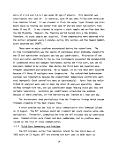

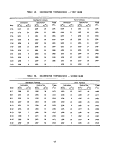

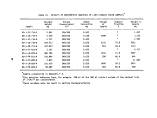

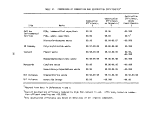

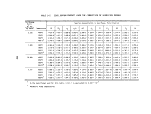

Data from the on-line analyzers and the results of the analyses of the

stack samples were used to calculate incineration efficiencies. Combustion

efficiencies were calculated from the on-line monitoring data. Four different

waste destruction efficiencies were calculated, one from the hydrocarbon ana-

lyzer data and three from laboratory analyses. These incineration efficiency

terms are defined in Table 1. Average values for the incineration efficiencies

are given in Table 2.

Results of the analyses by TRW, WSU, and BCL and of the reduction of the

on-line monitoring data indicate that the performance of the Vulcanus1 incin-

erators was consistently greater than 99.9% in terms of combustion and destruction

efficiencies for 2,4-D and 2,4,5-T and total organic material. Analyses of first

and third burn samples for TCDD led to destruction efficiencies greater than

99.9%. Analyses of second burn samples for TCDD led to destruction efficiencies

of >99.89% and >99.87%. The fact that these destruction efficiencies were appar-

ently marginally lower than the required 99.9% was because of problems during

the TCDD analyses (Section 4.2.5). Chemical interferences during the TCDD

analyses led to higher than usual detection limits. Although TCDD was detected

in only part of one of the second burn samples, the detection limits are such

that these two destruction efficiencies were calculated to be >99.89% and >99.87%

rather than 99.9%. It is considered, therefore, that the chemical interferences

TABLE 1. DEFINITION OF INCINERATION EFFICIENCY TERMS

Efficiency Term

Method of Calculation

Overall combustion efficiency DECE = 100 X [ % C02 ] - [ % CO ]

Total hydrocarbon (THC) DE

destruction efficiency

Herbicide Orange (HO) DE

destruction efficiency

TCDD destruction efficiency DE

Chlorinated hydrocarbon (CHC)

destruction efficiency

THC

HO

TCDD

C0

100 X [ THC fed ] - [ THC found ]

[ THC fed ]

= 100 X [ HO fed ] - [ HO found ]

[ HO fed ]

" 100 X [ TCDD fed ] - [ TCDD found ]

[ TCDD fed ]

= 100 X [ CHC fed ] - [ CHC found ]

[ CHC fed ]

image:

Data from the on-line analyzers and the results of the analyses of the

stack samples were used to calculate incineration efficiencies. Combustion

efficiencies were calculated from the on-line monitoring data. Four different

waste destruction efficiencies were calculated, one from the hydrocarbon ana-

lyzer data and three from laboratory analyses. These incineration efficiency

terms are defined in Table 1. Average values for the incineration efficiencies

are given in Table 2.

Results of the analyses by TRW, WSU, and BCL and of the reduction of the

on-line monitoring data indicate that the performance of the Vulcanus1 incin-

erators was consistently greater than 99.9% in terms of combustion and destruction

efficiencies for 2,4-D and 2,4,5-T and total organic material. Analyses of first

and third burn samples for TCDD led to destruction efficiencies greater than

99.9%. Analyses of second burn samples for TCDD led to destruction efficiencies

of >99.89% and >99.87%. The fact that these destruction efficiencies were appar-

ently marginally lower than the required 99.9% was because of problems during

the TCDD analyses (Section 4.2.5). Chemical interferences during the TCDD

analyses led to higher than usual detection limits. Although TCDD was detected

in only part of one of the second burn samples, the detection limits are such

that these two destruction efficiencies were calculated to be >99.89% and >99.87%

rather than 99.9%. It is considered, therefore, that the chemical interferences

TABLE 1. DEFINITION OF INCINERATION EFFICIENCY TERMS

Efficiency Term

Method of Calculation

Overall combustion efficiency DECE = 100 X [ % C02 ] - [ % CO ]

Total hydrocarbon (THC) DE

destruction efficiency

Herbicide Orange (HO) DE

destruction efficiency

TCDD destruction efficiency DE

Chlorinated hydrocarbon (CHC)

destruction efficiency

THC

HO

TCDD

C0

100 X [ THC fed ] - [ THC found ]

[ THC fed ]

= 100 X [ HO fed ] - [ HO found ]

[ HO fed ]

" 100 X [ TCDD fed ] - [ TCDD found ]

[ TCDD fed ]

= 100 X [ CHC fed ] - [ CHC found ]

[ CHC fed ]

image:

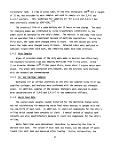

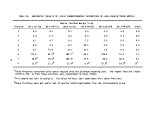

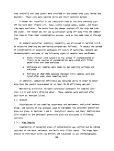

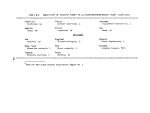

TABLE 2. SUMMARY OF CALCULATED INCINERATION EFFICIENCIES

DECE

DETHC

DEHO

DETCDD

DECHC

First

Burn

99.992

99.982

> 99. 999

>99.99

>99.999

Second

Burn

99.989

99.992

> 99. 999

>99.88

>99.999

Third

Burn

99.983

.(a)

> 99. 999

>99.96

> 99. 999

Combined

3 Burns

99.990

99.985

> 99. 999

>99.93

> 99. 999

Analyzer was inoperative during third burn

and not inadequate incinerator performance caused the marginal destruction

efficiencies. The extremely high destruction efficiencies for 2,4-D and 2,4,5-T

during the second burn (Section 6) support this contention.

Mostly glass components were incorporated in the sampling trains which

stood up well to the corrosive (HC1) combustion effluent. The on-line ana-

lyzer system functioned adequately and maintained adequate sensitivity for

measuring combustion gases. Some damage to the CO and hydrocarbon analyzers

occurred from the corrosive gases passing through them, necessitating more fre-

quent maintenance and calibration. The damage was caused by an engineering

oversight which left a cold spot in the system. Condensation thus occurred,

and it was the condensate that damaged the instruments. No effects from the

unusual shock vibration or saltwater environment were noted.

Incinerator controls and instrumentation were adequate. Redundant incin-

erator wall thermocouples would be desirable from an operational standpoint

because loss of wall thermocouples would shut off incineration and because they

cannot be replaced while the incinerators are hot.

8

image:

TABLE 2. SUMMARY OF CALCULATED INCINERATION EFFICIENCIES

DECE

DETHC

DEHO

DETCDD

DECHC

First

Burn

99.992

99.982

> 99. 999

>99.99

>99.999

Second

Burn

99.989

99.992

> 99. 999

>99.88

>99.999

Third

Burn

99.983

.(a)

> 99. 999

>99.96

> 99. 999

Combined

3 Burns

99.990

99.985

> 99. 999

>99.93

> 99. 999

Analyzer was inoperative during third burn

and not inadequate incinerator performance caused the marginal destruction

efficiencies. The extremely high destruction efficiencies for 2,4-D and 2,4,5-T

during the second burn (Section 6) support this contention.

Mostly glass components were incorporated in the sampling trains which

stood up well to the corrosive (HC1) combustion effluent. The on-line ana-

lyzer system functioned adequately and maintained adequate sensitivity for

measuring combustion gases. Some damage to the CO and hydrocarbon analyzers

occurred from the corrosive gases passing through them, necessitating more fre-

quent maintenance and calibration. The damage was caused by an engineering

oversight which left a cold spot in the system. Condensation thus occurred,

and it was the condensate that damaged the instruments. No effects from the

unusual shock vibration or saltwater environment were noted.

Incinerator controls and instrumentation were adequate. Redundant incin-

erator wall thermocouples would be desirable from an operational standpoint

because loss of wall thermocouples would shut off incineration and because they

cannot be replaced while the incinerators are hot.

8

image:

The personnel protection procedures described in Section 5 worked satis-

factorily. A boundary-isolation method of excluding Herbicide Orange from

living areas of the ship was used effectively. There were no major exposures

of personnel to Herbicide Orange. Minor exposures occurred during the first

burn when the incinerator exhaust plume impinged on the ship. Brief plume

impingements (5 to 60 seconds) resulted from burner flameouts caused by a

layer of material (later identified as water with traces of arsenic and sodium

salts of 2,4-D and 2,4,5-T) floating on top of the waste reaching the burners.

Flameouts were avoided subsequently by switching two of the three burners in

each incinerator to other tanks when nearing depletion of the waste tank being

pumped.

A significant result was derived from on-line monitoring data taken during

a traverse across the starboard stack. It was found that wall effects on the

combustion effluent gas composition from Herbicide Orange incineration were

nonexistent at distances greater than 10 cm from the inside incinerator wall

surface. Therefore, incinerator combustion efficiency could be determined

using a fixed position probe.

The at-sea incineration of Herbicide Orange was successfully completed.

The Permittees complied with all permit conditions related to at-sea operations

in the designated burn zone and listed in Section 1.2.

image:

The personnel protection procedures described in Section 5 worked satis-

factorily. A boundary-isolation method of excluding Herbicide Orange from

living areas of the ship was used effectively. There were no major exposures

of personnel to Herbicide Orange. Minor exposures occurred during the first

burn when the incinerator exhaust plume impinged on the ship. Brief plume

impingements (5 to 60 seconds) resulted from burner flameouts caused by a

layer of material (later identified as water with traces of arsenic and sodium

salts of 2,4-D and 2,4,5-T) floating on top of the waste reaching the burners.

Flameouts were avoided subsequently by switching two of the three burners in

each incinerator to other tanks when nearing depletion of the waste tank being

pumped.

A significant result was derived from on-line monitoring data taken during

a traverse across the starboard stack. It was found that wall effects on the

combustion effluent gas composition from Herbicide Orange incineration were

nonexistent at distances greater than 10 cm from the inside incinerator wall

surface. Therefore, incinerator combustion efficiency could be determined

using a fixed position probe.

The at-sea incineration of Herbicide Orange was successfully completed.

The Permittees complied with all permit conditions related to at-sea operations

in the designated burn zone and listed in Section 1.2.

image:

2. DESCRIPTION OF THE M/T VULCANUS

2.1 GENERAL LAYOUT OF VESSEL

The M/T Vulcanus, originally a cargo ship, was converted in 1972 to a

chemical tanker fitted with two large incinerators located at the stern. The

vessel meets all applicable requirements of the Intergovernmental Maritime

Consultative Organization (IMCO) concerning transport of dangerous cargo by

tanker. Figure 2 is a picture of the vessel, and Table 3 gives some of the

ship's specifications. Both the picture and the table were furnished by Ocean

Combustion Services, B.V., Rotterdam, The Netherlands, who manage the vessel.

Because of her size - an overall length of 102 meters, a beam of

14.4 meters, and a maximum draft of 7.4 meters - the Vulcanus is able to

Figure 2. M/T Vulcanus - incineration vessel

10

image:

2. DESCRIPTION OF THE M/T VULCANUS

2.1 GENERAL LAYOUT OF VESSEL

The M/T Vulcanus, originally a cargo ship, was converted in 1972 to a

chemical tanker fitted with two large incinerators located at the stern. The

vessel meets all applicable requirements of the Intergovernmental Maritime

Consultative Organization (IMCO) concerning transport of dangerous cargo by

tanker. Figure 2 is a picture of the vessel, and Table 3 gives some of the

ship's specifications. Both the picture and the table were furnished by Ocean

Combustion Services, B.V., Rotterdam, The Netherlands, who manage the vessel.

Because of her size - an overall length of 102 meters, a beam of

14.4 meters, and a maximum draft of 7.4 meters - the Vulcanus is able to

Figure 2. M/T Vulcanus - incineration vessel

10

image:

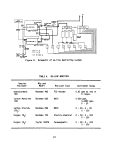

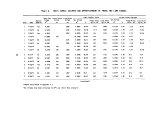

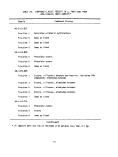

TABLE 3. SPECIFICATIONS OF THE M/T VULCANUS

Length overall

Breadth

Draft, maximum

Deadweight (DWT)

Speed

Tank capacity

Number of tanks

Tank coating

Loading equipment

Hose connection

Safety equipment

Waste to be processed

Incinerators

Per incinerator:

Overall height

Combustion chamber

OD

ID

Stack (top)

OD

ID

Waste feed (max)

Combustion air (max)

Burners (Vortex type)

Volume

Residence time

101.95 meters

14.40 meters

7.40 meters

4,768 metric tons

10-13 knots

3,503 cubic meters (cu m)

15, ranging in size from 115 cu m to

574 cu m

No coating in tanks, pipes, pumps, etc.

All equipment consists of low carbon

steel

Not available, but can be placed on

board, if required

10.2, 15.2, and 20.3 centimeters

(4,6, 8 inches)in diameter

Specially designed for this task and in

accordance with latest regulations of

IMCO, Scheepvaart-Inspectie (The Hague)

Must be liquid and pumpable. May con-

tain solid substances in pieces up to

5 centimeters in size. Must not attack

mild steel

10.45 m

5.5 m

4.8 m

3.8 m

3.4 m

12.5 metric tons/hour

90,000 m /hour

3

120 m3

1.0 sec at 1500 °C (calculated)

11

image:

TABLE 3. SPECIFICATIONS OF THE M/T VULCANUS

Length overall

Breadth

Draft, maximum

Deadweight (DWT)

Speed

Tank capacity

Number of tanks

Tank coating

Loading equipment

Hose connection

Safety equipment

Waste to be processed

Incinerators

Per incinerator:

Overall height

Combustion chamber

OD

ID

Stack (top)

OD

ID

Waste feed (max)

Combustion air (max)

Burners (Vortex type)

Volume

Residence time

101.95 meters

14.40 meters

7.40 meters

4,768 metric tons

10-13 knots

3,503 cubic meters (cu m)

15, ranging in size from 115 cu m to

574 cu m

No coating in tanks, pipes, pumps, etc.

All equipment consists of low carbon

steel

Not available, but can be placed on

board, if required

10.2, 15.2, and 20.3 centimeters

(4,6, 8 inches)in diameter

Specially designed for this task and in

accordance with latest regulations of

IMCO, Scheepvaart-Inspectie (The Hague)

Must be liquid and pumpable. May con-

tain solid substances in pieces up to

5 centimeters in size. Must not attack

mild steel

10.45 m

5.5 m

4.8 m

3.8 m

3.4 m

12.5 metric tons/hour

90,000 m /hour

3

120 m3

1.0 sec at 1500 °C (calculated)

11

image:

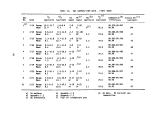

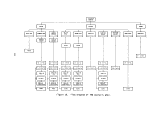

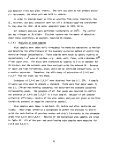

operate worldwide. Two diesel engines drive a single propeller to give cruis-

ing speeds of 10 to 13 knots. Her crew numbers 18; twelve to operate the ves-

sel and six to operate the incinerators.

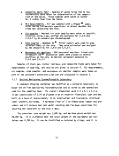

2.2 TANKS AND PUMPS

The Vulcanus is a double-hull, double-bottom vessel. Waste 1s carried in

15 cargo tanks which range in size from 115 to 574 cubic meters (m ) with an

overall capacity of 3503 m . Figure 3 is a schematic of the cargo tank layout.

Tanks are filled through a manifold on deck using a dockside loading pump.

During normal operation the waste tanks can be discharged only through the

incinerator feed system. There is, however, provision for discharging the cargo

into the ocean if an emergency arises. Piping system construction makes it

possible for any tank to be connected to either incinerator and for cargo to be

transferred from one tank to another.

The space between the two hulls is used for ballast. Ballast tanks may be

filled with seawater and emptied independently as required to trim and balance

the ship. Fuel oil is carried in tanks under and in the engine room. The

engine room is separated from the cargo tanks by double bulkheads. The pump

room and generator room are situated between the engine room and the waste

tanks.

TANK 6P

TANK 5P

TANK 4P

TANK 3P

TANK 2P

TANK 5C

TANK 6S

TANK 4C

TANK 5S

TANK 3C

TANK 4S

TANK 2C

TANK 3S

TANK 2S

PORT

TANK 1C

STARBOARD

P = PORT, C = CENTER, S = STARBOARD

Figure 3. Cargo tank layout schematic.

12

image:

operate worldwide. Two diesel engines drive a single propeller to give cruis-

ing speeds of 10 to 13 knots. Her crew numbers 18; twelve to operate the ves-

sel and six to operate the incinerators.

2.2 TANKS AND PUMPS

The Vulcanus is a double-hull, double-bottom vessel. Waste 1s carried in

15 cargo tanks which range in size from 115 to 574 cubic meters (m ) with an

overall capacity of 3503 m . Figure 3 is a schematic of the cargo tank layout.

Tanks are filled through a manifold on deck using a dockside loading pump.

During normal operation the waste tanks can be discharged only through the

incinerator feed system. There is, however, provision for discharging the cargo

into the ocean if an emergency arises. Piping system construction makes it

possible for any tank to be connected to either incinerator and for cargo to be

transferred from one tank to another.

The space between the two hulls is used for ballast. Ballast tanks may be

filled with seawater and emptied independently as required to trim and balance

the ship. Fuel oil is carried in tanks under and in the engine room. The

engine room is separated from the cargo tanks by double bulkheads. The pump

room and generator room are situated between the engine room and the waste

tanks.

TANK 6P

TANK 5P

TANK 4P

TANK 3P

TANK 2P

TANK 5C

TANK 6S

TANK 4C

TANK 5S

TANK 3C

TANK 4S

TANK 2C

TANK 3S

TANK 2S

PORT

TANK 1C

STARBOARD

P = PORT, C = CENTER, S = STARBOARD

Figure 3. Cargo tank layout schematic.

12

image:

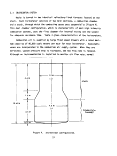

2.3 INCINERATOR SYSTEM

Waste is burned in two identical refractory-lined furnaces located at the

stern. Each incinerator consists of two main sections, a combustion chamber

and a stack, through which the combusting gases pass sequentially (Figure 4).

This dual chamber configuration, which is characteristic of most high intensity

combustion systems, uses the first chamber for internal mixing and the second

for adequate residence time. Table 3 gives characteristics of the incinerators.

Combustion air is supplied by large fixed speed blowers with a rated maxi-

mum capacity of 90,000 cubic meters per hour for each incinerator. Adjustable

vanes are incorporated in the combustion air supply system. When they are

deflected, system pressure drop is increased, and the flow rate is reduced.

Although no instrumentation is installed to monitor air flow rate, normal

4.6 M

3.4M.

I.D.

> STACK

1.6M

10.45 M

3.5 M

0.75M

i

4.8M

I.D.

COMBUSTION

CHAMBER

Figure 4. Incinerator configuration.

13

image:

2.3 INCINERATOR SYSTEM

Waste is burned in two identical refractory-lined furnaces located at the

stern. Each incinerator consists of two main sections, a combustion chamber

and a stack, through which the combusting gases pass sequentially (Figure 4).

This dual chamber configuration, which is characteristic of most high intensity

combustion systems, uses the first chamber for internal mixing and the second

for adequate residence time. Table 3 gives characteristics of the incinerators.

Combustion air is supplied by large fixed speed blowers with a rated maxi-

mum capacity of 90,000 cubic meters per hour for each incinerator. Adjustable

vanes are incorporated in the combustion air supply system. When they are

deflected, system pressure drop is increased, and the flow rate is reduced.

Although no instrumentation is installed to monitor air flow rate, normal

4.6 M

3.4M.

I.D.

> STACK

1.6M

10.45 M

3.5 M

0.75M

i

4.8M

I.D.

COMBUSTION

CHAMBER

Figure 4. Incinerator configuration.

13

image:

operation is stated by the ship's chief engineer to be between 75,000 and

80,000 cubic meters per hour at ambient conditions.

Liquid wastes are fed to the combustion system by means of electrically

driven pumps. Upstream of each burner supply pump is a device (Gorator) for

reducing the solids in the waste to a pumpable slurry. The Gorator also acts

as a mixing pump by recirculating the waste through the waste tank. Power for

the blowers, pumps and other parts of the incinerator system is supplied by

two diesel-generators with a total capacity of 750 kW at 440 volts and

60 Hertz.

Three burners of the vortex type are located at the same level on the

*

periphery of each furnace near its base. The burners are of a rotating cup,

concentric design and deliver waste or fuel oil through a central tube to an

atomization nozzle, where it meets high velocity air delivered through an

annulus. The burners are positioned as shown in Figure 5.

BURNER 6

BURNER 5

THERMOCOUPLE INDICATORS

(BLACK-BOX AND CONTROL PANEL)

(STARBOARD FURNACE)

THERMOCOUPLE FOR STARBOARD

FURNACE AUTOMATIC SHUT-OFF

BURNER 4

BURNER 3

BURNER 1

THERMOCOUPLE FOR PORT

FURNACE AUTOMATIC SHUT-OFF

THERMOCOUPLE INDICATORS

(BLACK BOX AND CONTROL PANEL)

(PORT FURNACE)

BURNER 2

Figure 5. Incineration system — burner and thermocouple locations.

14

image:

operation is stated by the ship's chief engineer to be between 75,000 and

80,000 cubic meters per hour at ambient conditions.

Liquid wastes are fed to the combustion system by means of electrically

driven pumps. Upstream of each burner supply pump is a device (Gorator) for

reducing the solids in the waste to a pumpable slurry. The Gorator also acts

as a mixing pump by recirculating the waste through the waste tank. Power for

the blowers, pumps and other parts of the incinerator system is supplied by