<pubnumber> 600R08031

600R08031 </pubnumber>

<title>

</pubnumber>

<title> Report

Report on the

on the  Geoelectrical

Geoelectrical

Detection

Detection of

of  Surfactant

Surfactant

Enhanced

Enhanced

Aquifer

Aquifer

Remediation

Remediation of

of  PCE

PCE :

:  Property

Property

Changes

Changes in

in  Aqueous

Aqueous

Solutions

Solutions

Due

Due to

to  Surfactant

Surfactant

Treatment

Treatment of

of  Perchloroethylene

Perchloroethylene :

:  Implications

Implications to

to  Geophysical

Geophysical

Measurements

Measurements </title>

<pages>121</pages>

<pubyear>2008</pubyear>

<provider>NEPIS</provider>

<access>online</access>

<origin>hardcopy</origin>

<author></author>

<publisher></publisher>

<subject></subject>

<abstract></abstract>

<operator>LM</operator>

<scandate>20100507</scandate>

<type>single page tiff</type>

<keyword></keyword>

vvEPA

United States

Environmental Protection

Agency

</title>

<pages>121</pages>

<pubyear>2008</pubyear>

<provider>NEPIS</provider>

<access>online</access>

<origin>hardcopy</origin>

<author></author>

<publisher></publisher>

<subject></subject>

<abstract></abstract>

<operator>LM</operator>

<scandate>20100507</scandate>

<type>single page tiff</type>

<keyword></keyword>

vvEPA

United States

Environmental Protection

Agency

Report

Report on the

on the  Geoelectrical

Geoelectrical

Detection

Detection of

of  Surfactant

Surfactant

Enhanced

Enhanced

Aquifer

Aquifer

Remediation

Remediation of

of  PCE

PCE :

:

Property

Property

Changes

Changes in

in  Aqueous

Aqueous

Solutions

Solutions

Due

Due to

to  Surfactant

Surfactant

Treatment

Treatment of

of  Perchloroethylene

Perchloroethylene :

:

Implications

Implications to

to  Geophysical

Geophysical

Measurements

Measurements RESEARCH AND DEVELOPMENT

image:

RESEARCH AND DEVELOPMENT

image:

EPA/600/R-08/031

April 2008

www.epa.gov

EPA/600/R-08/031

April 2008

www.epa.gov

Report

Report on the

on the  Geoelectrical

Geoelectrical

Detection

Detection of

of  Surfactant

Surfactant

Enhanced

Enhanced

Aquifer

Aquifer

Remediation

Remediation of

of  PCE

PCE :

:

Property

Property

Changes

Changes in

in  Aqueous

Aqueous

Solutions

Solutions

Due

Due to

to  Surfactant

Surfactant

Treatment

Treatment of

of  Perchloroethylene

Perchloroethylene :

:

Implications

Implications to

to  Geophysical

Geophysical

Measurements

Measurements by

D. Dale Werkema Jr., Ph.D.

U.S. Environmental Protection Agency

Office of Research and Development

National Exposure Research Laboratory

Environmental Sciences Division

Characterization and Monitoring Branch

Las Vegas, NV89119

Notice: Although this work was reviewed by EPA and approved for publication, it may not necessarily

reflect official Agency policy. Mention of trade names and commercial products does not

constitute endorsement or recommendation for use.

U.S. Environmental Protection Agency

Office of Research and Development

Washington, DC 20460

image:

by

D. Dale Werkema Jr., Ph.D.

U.S. Environmental Protection Agency

Office of Research and Development

National Exposure Research Laboratory

Environmental Sciences Division

Characterization and Monitoring Branch

Las Vegas, NV89119

Notice: Although this work was reviewed by EPA and approved for publication, it may not necessarily

reflect official Agency policy. Mention of trade names and commercial products does not

constitute endorsement or recommendation for use.

U.S. Environmental Protection Agency

Office of Research and Development

Washington, DC 20460

image:

Executive Summary

Select physicochemical properties of nine surfactants which are conventionally used in

the

Executive Summary

Select physicochemical properties of nine surfactants which are conventionally used in

the  remediation

remediation of

of  perchloroethylene

perchloroethylene (

( PCE

PCE , a.k.a. tetrachloroethene) were evaluated with

varying concentrations of

, a.k.a. tetrachloroethene) were evaluated with

varying concentrations of  PCE

PCE and indicator dyes in

and indicator dyes in  aqueous

aqueous

solutions

solutions using a response

surface quadratic design model of experiment. Stat-Ease Design Expert v7 was used to

generate the experimental design and perform the analysis. Two hundred forty

experiments were performed using

using a response

surface quadratic design model of experiment. Stat-Ease Design Expert v7 was used to

generate the experimental design and perform the analysis. Two hundred forty

experiments were performed using  PCE

PCE as a numerical factor (coded A) from 0 to 200

parts per million (ppm), dye type (coded B) as a 3-level categorical nominal factor, and

as a numerical factor (coded A) from 0 to 200

parts per million (ppm), dye type (coded B) as a 3-level categorical nominal factor, and

surfactant

surfactant type (coded C) as a 10-level categorical nominal factor. Five responses were

measured: temperature (°C), pH, conductivity (|0,S/cm), dissolved oxygen (DO, mg/L),

and density (g/mL). Diagnostics proved a normally distributed predictable response for

all of the measured responses except pH. The result from the Box-Cox plot for

transforms recommended a power transform for the conductivity response with lambda

(X) = 0.50, and for the DO response with, X = 2.2. The overall mean of the temperature

response proved to be a better predictor than the linear model. The conductivity response

is best fitted with a linear model using significant coded factors B and C. The DO model

is also linear with coded factors A, B, and C significant. The model for the density

response is a two factor interaction (2FI) model with significant coded factors C and AC.

Some of the

type (coded C) as a 10-level categorical nominal factor. Five responses were

measured: temperature (°C), pH, conductivity (|0,S/cm), dissolved oxygen (DO, mg/L),

and density (g/mL). Diagnostics proved a normally distributed predictable response for

all of the measured responses except pH. The result from the Box-Cox plot for

transforms recommended a power transform for the conductivity response with lambda

(X) = 0.50, and for the DO response with, X = 2.2. The overall mean of the temperature

response proved to be a better predictor than the linear model. The conductivity response

is best fitted with a linear model using significant coded factors B and C. The DO model

is also linear with coded factors A, B, and C significant. The model for the density

response is a two factor interaction (2FI) model with significant coded factors C and AC.

Some of the  surfactant

surfactant treatments of

treatments of  PCE

PCE significantly alter the conductivity, DO, and

density of the

significantly alter the conductivity, DO, and

density of the  aqueous

aqueous solution. However, the magnitude of the density response is so

small that it does not exceed the instrument tolerance. Results for the conductivity and

DO responses provide predictive models for the

solution. However, the magnitude of the density response is so

small that it does not exceed the instrument tolerance. Results for the conductivity and

DO responses provide predictive models for the  surfactant

surfactant

treatment

treatment of

of  PCE

PCE and may be

useful in determining the potential for geophysically monitoring

and may be

useful in determining the potential for geophysically monitoring  surfactant

surfactant

enhanced

enhanced

aquifer

aquifer

remediation

remediation (SEAR) of

(SEAR) of  PCE

PCE . As the

. As the  aqueous

aqueous physical properties change

physical properties change  due

due to

to

surfactant

surfactant

remediation

remediation efforts, so will the properties of the subsurface pore water, all of

which are influential factors in

efforts, so will the properties of the subsurface pore water, all of

which are influential factors in  geophysical

geophysical

measurements

measurements .

.  Geoelectrical

Geoelectrical methods are

potentially the best suited to measure SEAR alterations in the subsurface because the

conductivity of the pore fluid has the largest relative change. This research has provided

predictive models for alterations in the physicochemical properties of the pore fluid to

SEAR of

methods are

potentially the best suited to measure SEAR alterations in the subsurface because the

conductivity of the pore fluid has the largest relative change. This research has provided

predictive models for alterations in the physicochemical properties of the pore fluid to

SEAR of  PCE

PCE . Future investigations should address the contribution of the solid matrix

in the subsurface and the solid-fluid interaction during SEAR of

. Future investigations should address the contribution of the solid matrix

in the subsurface and the solid-fluid interaction during SEAR of  PCE

PCE contamination.

Disclaimer

The U.S. Environmental Protection Agency, through its Office of Research and

Development, performed the research described here using laboratory support under

contract work assignment EP-C-045-032: Lockheed Martin REAC. It has been subjected

to the Agency's peer and administrative review and has been approved for publication as

an EPA document. Mention of trade names or commercial products does not constitute

endorsement or recommendation for use.

image:

contamination.

Disclaimer

The U.S. Environmental Protection Agency, through its Office of Research and

Development, performed the research described here using laboratory support under

contract work assignment EP-C-045-032: Lockheed Martin REAC. It has been subjected

to the Agency's peer and administrative review and has been approved for publication as

an EPA document. Mention of trade names or commercial products does not constitute

endorsement or recommendation for use.

image:

Table of Contents

Executive Summary i

Disclaimer i

Table of Contents ii

List of Figures iii

List of Tables iii

Appendices '. iv

1.0 Introduction 1

2.0 Methodology 5

2.1 Experimental Set-up and Procedures 8

2.2 Quality Assurance / Quality Control 8

2.2.1 Temperature

Table of Contents

Executive Summary i

Disclaimer i

Table of Contents ii

List of Figures iii

List of Tables iii

Appendices '. iv

1.0 Introduction 1

2.0 Methodology 5

2.1 Experimental Set-up and Procedures 8

2.2 Quality Assurance / Quality Control 8

2.2.1 Temperature  Measurements

Measurements 8

2.2.2 pH

8

2.2.2 pH  Measurements

Measurements 9

2.2.3 Conductivity

9

2.2.3 Conductivity  Measurements

Measurements 9

2.2.4 Dissolved Oxygen

9

2.2.4 Dissolved Oxygen  Measurements

Measurements 9

2.2.5 Density

9

2.2.5 Density  Measurements

Measurements 10

2.2.6 GC/MS Volatile Compound Analyses 10

3.0 Results and Analysis 10

3.1 Quality Assurance / Quality Control 10

3.2 Temperature Response 11

3.3 pH Response 20

3.4 Conductivity Response 24

3.5 Dissolved Oxygen Response 33

3.6 Density Response 41

3.7 Response Summary 50

4.0 Discussion 55

4.1 Conductivity Response 55

4.2 Dissolved Oxygen Response 56

4.3

10

2.2.6 GC/MS Volatile Compound Analyses 10

3.0 Results and Analysis 10

3.1 Quality Assurance / Quality Control 10

3.2 Temperature Response 11

3.3 pH Response 20

3.4 Conductivity Response 24

3.5 Dissolved Oxygen Response 33

3.6 Density Response 41

3.7 Response Summary 50

4.0 Discussion 55

4.1 Conductivity Response 55

4.2 Dissolved Oxygen Response 56

4.3  Implications

Implications to

to  Geophysical

Geophysical Methods 56

5.0 Conclusions and

Methods 56

5.0 Conclusions and  Implications

Implications 60

6.0 Acknowledgements 61

7.0 References 62

Appendix A: QA/QC Protocols and Instrument Calibration Procedures 66

Appendix B: Standard Operating Procedure pH Meter 74

Appendix C: Standard Operating Procedure Conductivity Meter 83

Appendix D: Standard Operating Procedure Dissolved Oxygen Meter 92

Appendix E: Meter Calibration Data for QA Verification 100

Appendix F:

60

6.0 Acknowledgements 61

7.0 References 62

Appendix A: QA/QC Protocols and Instrument Calibration Procedures 66

Appendix B: Standard Operating Procedure pH Meter 74

Appendix C: Standard Operating Procedure Conductivity Meter 83

Appendix D: Standard Operating Procedure Dissolved Oxygen Meter 92

Appendix E: Meter Calibration Data for QA Verification 100

Appendix F:  PCE

PCE Concentration Sample Data for QA Verification 103

Appendix G: Cook's Distance 106

Appendix H: Glossary of Terms and Equations..' 108

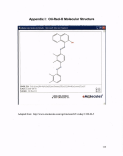

Appendix I: Oil-Red-O Molecular Structure 113

Appendix!: Brilliant Blue G-250 Molecular Structure 114

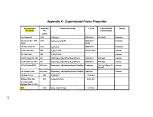

Appendix K: Experimental Factor Properties 115

11

image:

Concentration Sample Data for QA Verification 103

Appendix G: Cook's Distance 106

Appendix H: Glossary of Terms and Equations..' 108

Appendix I: Oil-Red-O Molecular Structure 113

Appendix!: Brilliant Blue G-250 Molecular Structure 114

Appendix K: Experimental Factor Properties 115

11

image:

List of Figures

1. Temperature Response Box-Cox Plot

2. Temperature Response Diagnostics

3. Temperature Response Residuals vs. Factors

4. Temperature Response Influence Plots

5. Temperature Response Dye vs.

List of Figures

1. Temperature Response Box-Cox Plot

2. Temperature Response Diagnostics

3. Temperature Response Residuals vs. Factors

4. Temperature Response Influence Plots

5. Temperature Response Dye vs.  Surfactant

Surfactant at

at  PCE

PCE Concentration =100 ppm

6. pH Box-Cox Plot for Power Transforms

7. pH Response Diagnostics

8. Conductivity Response Box-Cox Plot

9. Conductivity Normal Plot of Residuals: Linear and Cubic Model

10. Conductivity Response Diagnostics Plots

11. Conductivity Response Residuals vs. Factors

12. Conductivity Response Influence Plots

13. Conductivity Model Response Plots

14. Dissolved Oxygen Box-Cox Plot for Power Transforms

15. Dissolved Oxygen Response Diagnostic Plots

16. Dissolved Oxygen Response Residual vs. Factors

17. Dissolved Oxygen Response Influence Plots

18. Dissolved Oxygen Model Response Plots

19. Density Response Box-Cox Plot

20. Density Diagnostic Plots

21. Density Response Residuals vs. Factors

22. Density Response Influence Plots

23. Density Response Plot

List of Tables

I. Surfactants and Experimental Concentrations

II. Experimental Design Summary

III. Temperature Response Fit Summary

IV. Temperature Response ANOVA

V. pH Response Fit Summary

VI. pH Response ANOVA

VII. Conductivity Response Fit Summary

VIII. Conductivity Response ANOVA

DC. Dissolved Oxygen Response Fit Summary

X. Dissolved Oxygen Response ANOVA

XL Density Response Fit Summary

XII. Density Response ANOVA

XIII. Results Summary

XIV. Maximum and Minimum Modeled Response Summary

XV. Conductivity Model Response in Ascending Order

XVI. Dissolved Oxygen Model Response in Ascending Order

in

image:

Concentration =100 ppm

6. pH Box-Cox Plot for Power Transforms

7. pH Response Diagnostics

8. Conductivity Response Box-Cox Plot

9. Conductivity Normal Plot of Residuals: Linear and Cubic Model

10. Conductivity Response Diagnostics Plots

11. Conductivity Response Residuals vs. Factors

12. Conductivity Response Influence Plots

13. Conductivity Model Response Plots

14. Dissolved Oxygen Box-Cox Plot for Power Transforms

15. Dissolved Oxygen Response Diagnostic Plots

16. Dissolved Oxygen Response Residual vs. Factors

17. Dissolved Oxygen Response Influence Plots

18. Dissolved Oxygen Model Response Plots

19. Density Response Box-Cox Plot

20. Density Diagnostic Plots

21. Density Response Residuals vs. Factors

22. Density Response Influence Plots

23. Density Response Plot

List of Tables

I. Surfactants and Experimental Concentrations

II. Experimental Design Summary

III. Temperature Response Fit Summary

IV. Temperature Response ANOVA

V. pH Response Fit Summary

VI. pH Response ANOVA

VII. Conductivity Response Fit Summary

VIII. Conductivity Response ANOVA

DC. Dissolved Oxygen Response Fit Summary

X. Dissolved Oxygen Response ANOVA

XL Density Response Fit Summary

XII. Density Response ANOVA

XIII. Results Summary

XIV. Maximum and Minimum Modeled Response Summary

XV. Conductivity Model Response in Ascending Order

XVI. Dissolved Oxygen Model Response in Ascending Order

in

image:

Appendices

Appendix A. QA/QC Protocols and Instrument Calibration Procedures

Appendix B. Standard Operating Procedure pH Meter

Appendix C. Standard Operating Procedure Conductivity Meter

Appendix D. Standard Operating Procedure Dissolved Oxygen Meter

Appendix E. Meter Calibration Data for QA Verification

Appendix F.

Appendices

Appendix A. QA/QC Protocols and Instrument Calibration Procedures

Appendix B. Standard Operating Procedure pH Meter

Appendix C. Standard Operating Procedure Conductivity Meter

Appendix D. Standard Operating Procedure Dissolved Oxygen Meter

Appendix E. Meter Calibration Data for QA Verification

Appendix F.  PCE

PCE Concentration Sample Data for QA Verification

Appendix G. Cook's Distance

Appendix H. Glossary of Terms and Equations

Appendix I. Brilliant Blue Molecular Structure

Appendix J. Oil-Red-O Molecular Structure

Appendix K. Experimental Factor Properties

IV

image:

Concentration Sample Data for QA Verification

Appendix G. Cook's Distance

Appendix H. Glossary of Terms and Equations

Appendix I. Brilliant Blue Molecular Structure

Appendix J. Oil-Red-O Molecular Structure

Appendix K. Experimental Factor Properties

IV

image:

1.0 Introduction

The

1.0 Introduction

The  remediation

remediation of tetrachloroethene (commonly called

of tetrachloroethene (commonly called  perchloroethylene

perchloroethylene , or

, or

PCE

PCE ) in the near subsurface is generally accomplished using various technologies

including: oxidation, thermal heating, pump-and-treat, solvent/co-solvent flushing,

) in the near subsurface is generally accomplished using various technologies

including: oxidation, thermal heating, pump-and-treat, solvent/co-solvent flushing,

surfactant-enhanced

surfactant-enhanced

aquifer

aquifer

remediation

remediation (SEAR), and biologically mediated degradation.

The selected

(SEAR), and biologically mediated degradation.

The selected  remediation

remediation method(s) must be effective either individually, or in

combination, in degrading the

method(s) must be effective either individually, or in

combination, in degrading the  PCE

PCE to achieve acceptable health levels. The above

to achieve acceptable health levels. The above

remediation

remediation methods were evaluated to investigate the physical

methods were evaluated to investigate the physical  property

property

changes

changes which

may occur during their use in the

which

may occur during their use in the  remediation

remediation of

of  PCE

PCE . The evaluation was made with the

intent to understand the

. The evaluation was made with the

intent to understand the  implications

implications of these

of these  changes

changes to the

to the  geophysical

geophysical response.

Understanding and predicting the

response.

Understanding and predicting the  geophysical

geophysical response

response  due

due to the

to the  remediation

remediation of

of  PCE

PCE has widespread

has widespread  implications

implications to reduce clean up monitoring costs, measure the

effectiveness of

to reduce clean up monitoring costs, measure the

effectiveness of  remediation

remediation methods, and increase the overall efficiency of ground water

methods, and increase the overall efficiency of ground water

remediation

remediation efforts. Through non-invasive and minimally invasive surface

efforts. Through non-invasive and minimally invasive surface  geophysical

geophysical methods, the

methods, the  remediation

remediation and clean up of a contaminated site can be mapped and

monitored. Therefore, using this criterion, the

and clean up of a contaminated site can be mapped and

monitored. Therefore, using this criterion, the  remediation

remediation method should be effective at

reducing the

method should be effective at

reducing the  PCE

PCE concentration, yet be only mildly reactive with the subsurface so as not

to mask or overwhelm any potential

concentration, yet be only mildly reactive with the subsurface so as not

to mask or overwhelm any potential  geophysical

geophysical measurement method. Oxidation,

thermal, and pump-and-treat technologies are presently ruled out

measurement method. Oxidation,

thermal, and pump-and-treat technologies are presently ruled out  due

due to the geophysically

obvious or excessive reactions in the subsurface which may preclude the utility of

to the geophysically

obvious or excessive reactions in the subsurface which may preclude the utility of

geophysical

geophysical methods or not require their sophistication. With these three methods

excluded from the present study, solvent/co-solvent flushing, SEAR, and biological

degradation methods were chosen for future investigation. Additionally, the

methods or not require their sophistication. With these three methods

excluded from the present study, solvent/co-solvent flushing, SEAR, and biological

degradation methods were chosen for future investigation. Additionally, the  remediation

remediation of

of  PCE

PCE using SEAR has proven successful used either alone or in concert with another

method, such as biological breakdown (Rothmel et al., 1998). Furthermore, outside of

the environmental

using SEAR has proven successful used either alone or in concert with another

method, such as biological breakdown (Rothmel et al., 1998). Furthermore, outside of

the environmental  remediation

remediation industry, some commonly used surfactants are among the

most common pollutants in soils resulting from their ubiquity in household products,

industrial processes, and pesticides (Pin-Hua et al., 2006). Therefore, this study focuses

on the

industry, some commonly used surfactants are among the

most common pollutants in soils resulting from their ubiquity in household products,

industrial processes, and pesticides (Pin-Hua et al., 2006). Therefore, this study focuses

on the  aqueous

aqueous physicochemical

physicochemical  changes

changes that occur during the

that occur during the  remediation

remediation of a dense

of a dense

non-aqueous

non-aqueous liquid (DNAPL); e.g.,

liquid (DNAPL); e.g.,  PCE

PCE , using the surfactants conventionally employed

in SEAR technology. The other possible

, using the surfactants conventionally employed

in SEAR technology. The other possible  remediation

remediation methods will be examined in future

experiments.

methods will be examined in future

experiments.

Geophysical

Geophysical methods, such as ground penetrating radar, seismic reflection and

refraction, or electrical resistivity, can be used to generate an image of the near

subsurface determined by the geometrical distribution of the

methods, such as ground penetrating radar, seismic reflection and

refraction, or electrical resistivity, can be used to generate an image of the near

subsurface determined by the geometrical distribution of the  geophysical

geophysical properties of the

subsurface.

properties of the

subsurface.  Geophysical

Geophysical properties are simply the physical properties of a volume of

earth. Examples include the electrical resistivity, magnetic susceptibility, and seismic

velocity. The image of the

properties are simply the physical properties of a volume of

earth. Examples include the electrical resistivity, magnetic susceptibility, and seismic

velocity. The image of the  geophysical

geophysical properties is

properties is  due

due to the material properties of the

subsurface volume of interest, which include the solid, liquid, and vapor phases. The

to the material properties of the

subsurface volume of interest, which include the solid, liquid, and vapor phases. The

geophysical

geophysical properties of a volume of earth containing these materials are determined by

the physical, chemical, and biological properties of the individual materials as well as the

interaction of these properties (Knight and Endres, 2005). A physical

properties of a volume of earth containing these materials are determined by

the physical, chemical, and biological properties of the individual materials as well as the

interaction of these properties (Knight and Endres, 2005). A physical  property

property is a

characteristic that can be observed for a material without changing its chemical identity.

image:

is a

characteristic that can be observed for a material without changing its chemical identity.

image:

A chemical

A chemical  property

property , on the other hand, is only observed by changing a substance's

chemical identity, and a biological

, on the other hand, is only observed by changing a substance's

chemical identity, and a biological  property

property can be determined by the organism's activity.

Physical

can be determined by the organism's activity.

Physical  property

property attributes include the electrical conductivity, temperature, density,

dielectric, and acoustic properties.

attributes include the electrical conductivity, temperature, density,

dielectric, and acoustic properties.  Geophysical

Geophysical methods measure these physical

properties

methods measure these physical

properties  due

due to the bulk response of the subsurface volume, which includes the solid,

liquid, and gas portions as well as the chemical and biological interactions. In

applications of geophysics to contaminant and

to the bulk response of the subsurface volume, which includes the solid,

liquid, and gas portions as well as the chemical and biological interactions. In

applications of geophysics to contaminant and  remediation

remediation efforts, the geologic material

in which the contaminant (e.g.,

efforts, the geologic material

in which the contaminant (e.g.,  PCE

PCE ) exists and into which the

) exists and into which the  remediation

remediation method (e.g.,

SEAR) would be introduced impacts the

method (e.g.,

SEAR) would be introduced impacts the  geophysical

geophysical response because the physical,

chemical, and biological properties of the subsurface are altered. In addition, the

components of the geologic media involve several levels of complexity. First, the

geologic media itself generates a

response because the physical,

chemical, and biological properties of the subsurface are altered. In addition, the

components of the geologic media involve several levels of complexity. First, the

geologic media itself generates a  geophysical

geophysical response as a result of the specific physical

properties of the solid material. Second, the interaction between the geologic media and

natural subsurface fluids and their specific properties (e.g., pH) adds another component

of the

response as a result of the specific physical

properties of the solid material. Second, the interaction between the geologic media and

natural subsurface fluids and their specific properties (e.g., pH) adds another component

of the  geophysical

geophysical response. Additionally, any contaminate will interact with the natural

subsurface solid and liquid phases and result in

response. Additionally, any contaminate will interact with the natural

subsurface solid and liquid phases and result in  changes

changes to the measured

to the measured  geophysical

geophysical system. Evaluation of the

system. Evaluation of the  geophysical

geophysical response with multiple geologic and groundwater

conditions, a range of

response with multiple geologic and groundwater

conditions, a range of  PCE

PCE concentrations, and varying

concentrations, and varying  surfactant

surfactant treatments, presents a

very complex investigation. Therefore, as an initial investigation and to simplify the

potential reactions and interactions between the different media, this project focuses on

treatments, presents a

very complex investigation. Therefore, as an initial investigation and to simplify the

potential reactions and interactions between the different media, this project focuses on

changes

changes only in the

only in the  aqueous

aqueous phase. The experiments are designed to provide a predictive

model for select

phase. The experiments are designed to provide a predictive

model for select  aqueous

aqueous phase properties

phase properties  due

due to the

to the  surfactant

surfactant

remediation

remediation of

of  PCE

PCE .

Much work has been done on the use of surfactants to both solubilize and

mobilize

.

Much work has been done on the use of surfactants to both solubilize and

mobilize  PCE

PCE (Conrad et al., 2002; Dwarakanath et al., 1999; Londergan et al, 2001;

McGuire and Hughes, 2003; Rommel et al., 1998; Sabatini et al., 1996; Taylor et al.,

2004; West and Harwell, 1992). Briefly, SEAR involves the injection of surfactants into

the subsurface to recover NAPL-contaminants by either

(Conrad et al., 2002; Dwarakanath et al., 1999; Londergan et al, 2001;

McGuire and Hughes, 2003; Rommel et al., 1998; Sabatini et al., 1996; Taylor et al.,

2004; West and Harwell, 1992). Briefly, SEAR involves the injection of surfactants into

the subsurface to recover NAPL-contaminants by either  enhanced

enhanced solubilization or

mobilization

solubilization or

mobilization  due

due to interfacial tension reduction. Surfactants are surface active agents

(Sabatini et al., 1995) the molecules of which are composed of a hydrophilic tail and a

hydrophobic head. This results in the molecule's behavior in the formation of

microemulsions. Microemulsions are thermodynamically stable and swollen micellular

to interfacial tension reduction. Surfactants are surface active agents

(Sabatini et al., 1995) the molecules of which are composed of a hydrophilic tail and a

hydrophobic head. This results in the molecule's behavior in the formation of

microemulsions. Microemulsions are thermodynamically stable and swollen micellular

solutions

solutions . Surfactants may be cationic, nonionic, anionic, or zwitterionic. The use of

anionic surfactants is the most common because these tend not to adsorb (because of like

charges) to native negatively charged subsurface solid material as do cationic types

(Dwarakanath et al., 1999). Zwitterionic surfactants are rarely used in the field for

. Surfactants may be cationic, nonionic, anionic, or zwitterionic. The use of

anionic surfactants is the most common because these tend not to adsorb (because of like

charges) to native negatively charged subsurface solid material as do cationic types

(Dwarakanath et al., 1999). Zwitterionic surfactants are rarely used in the field for

remediation

remediation . Surfactants that disrupt structure are best for microemulsions of DNAPLs.

Surfactants used for

. Surfactants that disrupt structure are best for microemulsions of DNAPLs.

Surfactants used for  remediation

remediation can be engineered such that the optimization of the

can be engineered such that the optimization of the

surfactant

surfactant for performance does not create another environmental problem. The use of

surfactants has resulted in greater than 99% contaminant removal in soil columns

(Dwarakanath and Pope, 2000), 96.9% in other soil column studies (Sabatini et al., 2000),

98.5 % DNAPL removed from an alluvial

for performance does not create another environmental problem. The use of

surfactants has resulted in greater than 99% contaminant removal in soil columns

(Dwarakanath and Pope, 2000), 96.9% in other soil column studies (Sabatini et al., 2000),

98.5 % DNAPL removed from an alluvial  aquifer

aquifer (Londergan et al., 2001), 90% recovery

of

(Londergan et al., 2001), 90% recovery

of  PCE

PCE in bench scale studies (Conrad et al., 2002), and 97%

in bench scale studies (Conrad et al., 2002), and 97%  PCE

PCE extraction in others

(Sabatini et al., 1996). For this project, nine surfactants (factor coded C) were selected

for experimentation, as determined from those most prevalently used, and those which

contained the two primary charge types, nonionic and anionic. The

extraction in others

(Sabatini et al., 1996). For this project, nine surfactants (factor coded C) were selected

for experimentation, as determined from those most prevalently used, and those which

contained the two primary charge types, nonionic and anionic. The  surfactant

surfactant 4% Tween

image:

4% Tween

image:

80, a polyoxyethylene-20-sorbitan monooleate is nonionic. This

80, a polyoxyethylene-20-sorbitan monooleate is nonionic. This  surfactant

surfactant , both alone

and with 10% EtOH, has been used by many researchers (McGuire and Hughes, 2003;

Ramsburg and Pennell, 2000; Taylor et al., 2004) and was chosen

, both alone

and with 10% EtOH, has been used by many researchers (McGuire and Hughes, 2003;

Ramsburg and Pennell, 2000; Taylor et al., 2004) and was chosen  due

due to its prevalence,

nonionic characteristics, and its efficacy at

to its prevalence,

nonionic characteristics, and its efficacy at  PCE

PCE removal. In addition, it has been used

with the two dye types employed in this experiment as described below. Fifty mM

Tween 60, a polyoxyethylene-20-sorbitan monostearate, is also nonionic and has shown

good solubilization of

removal. In addition, it has been used

with the two dye types employed in this experiment as described below. Fifty mM

Tween 60, a polyoxyethylene-20-sorbitan monostearate, is also nonionic and has shown

good solubilization of  PCE

PCE (Sabatini et al., 1996). The

(Sabatini et al., 1996). The  surfactant

surfactant 0.5% AMA-80-I is a

low concentration of the anionic sodium dihexyl sulfosuccinate and was found to

successfully solubilize

0.5% AMA-80-I is a

low concentration of the anionic sodium dihexyl sulfosuccinate and was found to

successfully solubilize  PCE

PCE without producing a false

without producing a false  PCE

PCE saturation in column

experiments (Cho et al., 2004). A higher concentration of approximately'8% AMA-80-I

was shown to successfully remove

saturation in column

experiments (Cho et al., 2004). A higher concentration of approximately'8% AMA-80-I

was shown to successfully remove  PCE

PCE by two orders of magnitude in a field study

(Londergan et al., 2001). Steol CS-330 is the anionic sodium laureth sulfate + alcohol

ethoxylate and was used at 0.025% and 0.10% concentrations. The levels of Steol CS-

330 were included because they were shown to emulsify trichloroethylene (TCE) and

were biocompatible with a bio-variant, ENV-435, which is very specialized and can

degrade TCE (Rothmel et al., 1998). Cho et al., (2004) also investigated 0.5% and 5%

Dowfax 8390 in batch and column experiments to detect the magnitude of artifacts

introduced while estimating DNAPL content. In summary, Table I shows the ten

by two orders of magnitude in a field study

(Londergan et al., 2001). Steol CS-330 is the anionic sodium laureth sulfate + alcohol

ethoxylate and was used at 0.025% and 0.10% concentrations. The levels of Steol CS-

330 were included because they were shown to emulsify trichloroethylene (TCE) and

were biocompatible with a bio-variant, ENV-435, which is very specialized and can

degrade TCE (Rothmel et al., 1998). Cho et al., (2004) also investigated 0.5% and 5%

Dowfax 8390 in batch and column experiments to detect the magnitude of artifacts

introduced while estimating DNAPL content. In summary, Table I shows the ten

surfactant

surfactant categories used in this study, their respective experimental factor code,

components and concentration, ionic type, and the source reference.

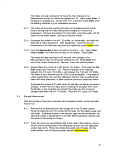

Table I: Surfactants and Experimental Concentrations

Coded

Factor

Cl

C2

C3

C4

C5

C6

C7

C8

C9

CIO

categories used in this study, their respective experimental factor code,

components and concentration, ionic type, and the source reference.

Table I: Surfactants and Experimental Concentrations

Coded

Factor

Cl

C2

C3

C4

C5

C6

C7

C8

C9

CIO

Surfactant

Surfactant concentration (w/w)

in DI water

4% Tween 80

4% Tween 80 +10%

EtOH

50 mM Tween 60

0.5% AMA-80-I

8% AMA-80-I

0.025% Steol CS-330

0.10% Steol CS-330

0.5% Dowfax 8390

5% Dowfax 8390

No

concentration (w/w)

in DI water

4% Tween 80

4% Tween 80 +10%

EtOH

50 mM Tween 60

0.5% AMA-80-I

8% AMA-80-I

0.025% Steol CS-330

0.10% Steol CS-330

0.5% Dowfax 8390

5% Dowfax 8390

No  surfactant

surfactant Comments

Polyoxyethylene-20-

Sorbitan monooleate

Polyoxyethylene-20-

Sorbitan monostearate

Sodium dihexyl

sulfosuccinate

Sodium laureth sulfate +

Alcohol ethoxylate

Sodium hexadecyl

diphenyl oxide +

Disodium

dihexyldecyldiphenyl

oxide + Sodium sulfate

—

Charge type

nonionic

anionic

—

Reference

Taylor et al., 2004

Ramsburg and

Pennell, 2000;

Taylor et al., 2004

Sabatina et al., 1996

Cho et al., 2004

Londergan et al.,

2001; Ramsburg

and Pennell, 2000

Rothmel et al., 1998

Rothmel et al., 1998

Cho et al., 2004

Cho et al., 2004

....

image:

Comments

Polyoxyethylene-20-

Sorbitan monooleate

Polyoxyethylene-20-

Sorbitan monostearate

Sodium dihexyl

sulfosuccinate

Sodium laureth sulfate +

Alcohol ethoxylate

Sodium hexadecyl

diphenyl oxide +

Disodium

dihexyldecyldiphenyl

oxide + Sodium sulfate

—

Charge type

nonionic

anionic

—

Reference

Taylor et al., 2004

Ramsburg and

Pennell, 2000;

Taylor et al., 2004

Sabatina et al., 1996

Cho et al., 2004

Londergan et al.,

2001; Ramsburg

and Pennell, 2000

Rothmel et al., 1998

Rothmel et al., 1998

Cho et al., 2004

Cho et al., 2004

....

image:

The second factor (coded B) investigated in this experiment was the use of dyes

for visually tracking

The second factor (coded B) investigated in this experiment was the use of dyes

for visually tracking  PCE

PCE migration and movement in the subsurface. Because

migration and movement in the subsurface. Because  PCE

PCE is a

clear liquid, visual observations of subsurface migration is very difficult. As a result,

investigators have used

is a

clear liquid, visual observations of subsurface migration is very difficult. As a result,

investigators have used  PCE-soluble

PCE-soluble dyes to observe subsurface

dyes to observe subsurface  PCE

PCE migration in

laboratory experiments (Jeong et al., 2002; Longino and Kueper, 1994; Taylor et al.,

2001). Two conservative and non-reactive dyes were used: Oil-Red-O and Brilliant

Blue-G250 each at a concentration of 10"4 Molar (Jeong et al., 2002; Taylor et al., 2001;

Taylor et al., 2004). Taylor et al., (2001) showed that this concentration of Oil-Red-O

has no significant effect on the solubilization, interfacial tension, and viscosity of

migration in

laboratory experiments (Jeong et al., 2002; Longino and Kueper, 1994; Taylor et al.,

2001). Two conservative and non-reactive dyes were used: Oil-Red-O and Brilliant

Blue-G250 each at a concentration of 10"4 Molar (Jeong et al., 2002; Taylor et al., 2001;

Taylor et al., 2004). Taylor et al., (2001) showed that this concentration of Oil-Red-O

has no significant effect on the solubilization, interfacial tension, and viscosity of  PCE

PCE .

Other research shows that the presence of Oil-Red-O does alter the interfacial tension

between

.

Other research shows that the presence of Oil-Red-O does alter the interfacial tension

between  PCE

PCE and water or

and water or  PCE

PCE and ethanol

and ethanol  solutions

solutions (Jeong et al., 2002; Longino and

Kueper, 1994). Furthermore, the DNAPL migration into porous media is altered

(Jeong et al., 2002; Longino and

Kueper, 1994). Furthermore, the DNAPL migration into porous media is altered  due

due to

the effect of altering the surface tension of

to

the effect of altering the surface tension of  PCE

PCE (Jeong et al., 2002). Further research

found that dye use increases DNAPL surface chemical complexity and increases

(Jeong et al., 2002). Further research

found that dye use increases DNAPL surface chemical complexity and increases  PCE

PCE mobility through lower adhesion tension (Tuck and Iversen, 2003). To determine if the

use of these dyes results in

mobility through lower adhesion tension (Tuck and Iversen, 2003). To determine if the

use of these dyes results in  changes

changes to the responses measured, dye type was included as

a categorical (nominal) factor in this experimental design. The three dye type categories

were none, Oil-Red-O, and Brilliant Blue-G250.

The final experimental factor (coded A) was

to the responses measured, dye type was included as

a categorical (nominal) factor in this experimental design. The three dye type categories

were none, Oil-Red-O, and Brilliant Blue-G250.

The final experimental factor (coded A) was  PCE

PCE concentration.

concentration.  Surfactant

Surfactant

remediation

remediation of

of  PCE

PCE is typically utilized for residual or saturated

is typically utilized for residual or saturated  PCE

PCE concentrations.

Free-phase

concentrations.

Free-phase  PCE

PCE is typically treated with other technologies. Furthermore, the laboratory

equipment utilized in these experiments is not robust enough to withstand free-phase

concentrations of

is typically treated with other technologies. Furthermore, the laboratory

equipment utilized in these experiments is not robust enough to withstand free-phase

concentrations of  PCE

PCE . Therefore, the highest concentration of

. Therefore, the highest concentration of  PCE

PCE was its

was its  aqueous

aqueous solubility at room temperature (25°C), 200 ppm (NIOSH, 1994). A total of five

solubility at room temperature (25°C), 200 ppm (NIOSH, 1994). A total of five  PCE

PCE concentrations were used to occupy the design space: 0, 50, 100, 150, and 200 ppm

concentrations were used to occupy the design space: 0, 50, 100, 150, and 200 ppm  PCE

PCE .

Thus, the objective of this initial phase of the research was to determine the

relationship of the temperature, conductivity, dissolved oxygen, pH, and density of the

.

Thus, the objective of this initial phase of the research was to determine the

relationship of the temperature, conductivity, dissolved oxygen, pH, and density of the

aqueous

aqueous solution as a function of

solution as a function of  surfactant

surfactant type,

type,  PCE

PCE concentration, and dye type. The

evaluation of the resulting

concentration, and dye type. The

evaluation of the resulting  aqueous

aqueous properties will provide an initial understanding of the

potential

properties will provide an initial understanding of the

potential  geophysical

geophysical response to the SEAR of

response to the SEAR of  PCE

PCE .

image:

.

image:

2.0 Methodology

The response surface methods (RSM) for experimental design is typically used

for product process enhancement or the identification of the high plateaus or peaks of

product quality or process efficiency (Anderson and Whitcomb, 2000; Anderson and

Whitcomb, 2005). The RSM includes mathematical and statistical techniques used for

modeling and analysis of problems involving a response of interest which is influenced

by several variables where the objective is to optimize the response (Montgomery, 1997).

This methodology has had much success in industrial applications and the application of

RSM to physicochemical

2.0 Methodology

The response surface methods (RSM) for experimental design is typically used

for product process enhancement or the identification of the high plateaus or peaks of

product quality or process efficiency (Anderson and Whitcomb, 2000; Anderson and

Whitcomb, 2005). The RSM includes mathematical and statistical techniques used for

modeling and analysis of problems involving a response of interest which is influenced

by several variables where the objective is to optimize the response (Montgomery, 1997).

This methodology has had much success in industrial applications and the application of

RSM to physicochemical  property

property

changes

changes in an

in an  aqueous

aqueous solution utilizes the same

mathematics, but with a different frame of reference. For example, Montgomery (1997)

uses the example of a chemical engineer trying to maximize the yield (y) of a process,

which is dependent upon the levels of temperature (xi) and pressure (x2). The yield is,

therefore, a function of the levels of the temperature and pressure, such that;

y = f(xltx2)+e

where £ is the noise, error, or uncertainty observed in the response. Montgomery (1997)

goes on to suggest denoting the expected response as E(y) =flxi,\2~) = rj. Therefore, the

surface represented by TJ = f(x},x2) is termed a response surface (Montgomery, 1997).

The application of the RSM to the response prediction of

solution utilizes the same

mathematics, but with a different frame of reference. For example, Montgomery (1997)

uses the example of a chemical engineer trying to maximize the yield (y) of a process,

which is dependent upon the levels of temperature (xi) and pressure (x2). The yield is,

therefore, a function of the levels of the temperature and pressure, such that;

y = f(xltx2)+e

where £ is the noise, error, or uncertainty observed in the response. Montgomery (1997)

goes on to suggest denoting the expected response as E(y) =flxi,\2~) = rj. Therefore, the

surface represented by TJ = f(x},x2) is termed a response surface (Montgomery, 1997).

The application of the RSM to the response prediction of  aqueous

aqueous properties is a direct

analogue to the industrial application and can be thought of as maximizing or optimizing

the response, conductivity, for example,

properties is a direct

analogue to the industrial application and can be thought of as maximizing or optimizing

the response, conductivity, for example,  due

due to certain factors or factor interactions. The

RSM was used in this application to model the dependent variable or responses, in this

case, the particular

to certain factors or factor interactions. The

RSM was used in this application to model the dependent variable or responses, in this

case, the particular  aqueous

aqueous

property

property (i.e., temperature, pH, conductivity, dissolved

oxygen, or density)

(i.e., temperature, pH, conductivity, dissolved

oxygen, or density)  due

due to the factors:

to the factors:  PCE

PCE concentration, dye type,

concentration, dye type,  surfactant

surfactant type, or

the interaction of these factors. In terms of the example above given by Montgomery

(1997), the yield (yi) would be the responses, or in our case, the

type, or

the interaction of these factors. In terms of the example above given by Montgomery

(1997), the yield (yi) would be the responses, or in our case, the  aqueous

aqueous properties where

i= temperature, pH, conductivity, dissolved oxygen, or density. The factors (xk) are the

independent variables where k=PCE concentration, dye type,

properties where

i= temperature, pH, conductivity, dissolved oxygen, or density. The factors (xk) are the

independent variables where k=PCE concentration, dye type,  surfactant

surfactant type, or the

interactions of these factors. Therefore, the RSM experimental design was chosen to

provide a response surface to navigate the experimental space and determine the response

(yi) per each factor or factor interaction (xk). If the three experimental factors are

significant to the particular response and the particular model assumptions are valid, then

each of the five responses will produce a response as a function of the three experimental

factors. Further details of the response surface method in experimental design can be

found in several sources (Anderson and Whitcomb, 2005; Montgomery, 1997).

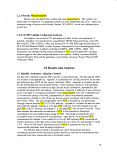

The summary of the design is as follows. The three factors are coded A, B, and

C. A is

type, or the

interactions of these factors. Therefore, the RSM experimental design was chosen to

provide a response surface to navigate the experimental space and determine the response

(yi) per each factor or factor interaction (xk). If the three experimental factors are

significant to the particular response and the particular model assumptions are valid, then

each of the five responses will produce a response as a function of the three experimental

factors. Further details of the response surface method in experimental design can be

found in several sources (Anderson and Whitcomb, 2005; Montgomery, 1997).

The summary of the design is as follows. The three factors are coded A, B, and

C. A is  PCE

PCE concentration, B is dye type, and C is

concentration, B is dye type, and C is  surfactant

surfactant type.

type.  PCE

PCE type is a

numeric factor with concentrations of 0, 50, 100, 150, and 200 ppm, the latter being the

top limit of the

type is a

numeric factor with concentrations of 0, 50, 100, 150, and 200 ppm, the latter being the

top limit of the  aqueous

aqueous solubility of

solubility of  PCE

PCE at 25°C (NIOSH, 1994). Dye type is a nominal

categorical factor with three levels: none or no dye, Oil-Red-O (Solvent Red 27, formula

weight = 408.5), and Brilliant Blue-G 250 (FW = 854.02). The dyes are added to the

experimental

at 25°C (NIOSH, 1994). Dye type is a nominal

categorical factor with three levels: none or no dye, Oil-Red-O (Solvent Red 27, formula

weight = 408.5), and Brilliant Blue-G 250 (FW = 854.02). The dyes are added to the

experimental  solutions

solutions to achieve a final concentration of 10"4 Molar.

to achieve a final concentration of 10"4 Molar.  Surfactant

Surfactant type is

also a nominal categorical factor with 10 levels as described in Table I. The RSM design

image:

type is

also a nominal categorical factor with 10 levels as described in Table I. The RSM design

image:

of choice is the one numerical factor RSM design. The number of levels required of the

numerical factor determines the order of the polynomial. In this case, five levels of a

single factor (i.e.,

of choice is the one numerical factor RSM design. The number of levels required of the

numerical factor determines the order of the polynomial. In this case, five levels of a

single factor (i.e.,  PCE

PCE at the levels indicated above), plus replicates, allow a lack-of-fit

analysis (see Appendix H for definition) and a purely experimental uncertainty

determination for a quadratic model. Additionally, this RSM design allows the addition

of categorical factors (Stat-Ease, 2006). Therefore, this investigation is designed with a

response surface methodology quadratic design model with no blocking. Blocking is a

technique which can be used to remove the expected variation caused by some change

during the course of the experiment. A general rule of thumb for blocking is to only

block on a factor that one is not interested in studying (the block is aliased with the

chosen, usually insignificant, factor, which is usually a high order interaction). No

blocking was chosen for this experiment. Per the RSM experimental quadratic design

model 240 experimental runs were performed, which is determined from 1 numeric

factor, A at 5 levels, 2 nominal categorical factors; B at 3 levels and C at 10 levels, with

duplication for every combination of the categorical factor levels, and with 60 center

points. The five responses measured were: temperature (°C), conductivity (fiS/cm),

dissolved oxygen (DO, mg/L), pH, and density (g/mL). The experimental design was set

up using Design Expert v7 from Stat-Ease, Inc. (Stat-Ease, 2006). The software sets up

the randomized run order and replicates as necessary per the model design. The

experimental design is summarized in Table II.

image:

at the levels indicated above), plus replicates, allow a lack-of-fit

analysis (see Appendix H for definition) and a purely experimental uncertainty

determination for a quadratic model. Additionally, this RSM design allows the addition

of categorical factors (Stat-Ease, 2006). Therefore, this investigation is designed with a

response surface methodology quadratic design model with no blocking. Blocking is a

technique which can be used to remove the expected variation caused by some change

during the course of the experiment. A general rule of thumb for blocking is to only

block on a factor that one is not interested in studying (the block is aliased with the

chosen, usually insignificant, factor, which is usually a high order interaction). No

blocking was chosen for this experiment. Per the RSM experimental quadratic design

model 240 experimental runs were performed, which is determined from 1 numeric

factor, A at 5 levels, 2 nominal categorical factors; B at 3 levels and C at 10 levels, with

duplication for every combination of the categorical factor levels, and with 60 center

points. The five responses measured were: temperature (°C), conductivity (fiS/cm),

dissolved oxygen (DO, mg/L), pH, and density (g/mL). The experimental design was set

up using Design Expert v7 from Stat-Ease, Inc. (Stat-Ease, 2006). The software sets up

the randomized run order and replicates as necessary per the model design. The

experimental design is summarized in Table II.

image:

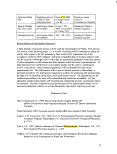

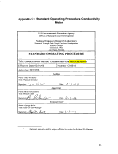

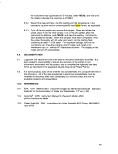

Table II: Experimental Design Summary

Response

Study Type: Surface Runs

Initial No

Design: One Factor Blocks

Design

Model: Quadratic

240

Factor

A

B

C

Response

Y1

Y2

Y3

Y4

Y5

Name

PCEconc

Dye

Table II: Experimental Design Summary

Response

Study Type: Surface Runs

Initial No

Design: One Factor Blocks

Design

Model: Quadratic

240

Factor

A

B

C

Response

Y1

Y2

Y3

Y4

Y5

Name

PCEconc

Dye

Surfactant

Surfactant Name

Temp

Cond

DO

PH

density

Units

ppm

type

type

Units

degC

uS/cm

mg/L

-logio[H+]

g/mL

Type

Numeric

Categoric

Categoric

Obs

240

240

240

240

240

Low

Actual

0

none

4% Tween

80

Analysis

Polynomial

Polynomial

Polynomial

Polynomial

Polynomial

High

Actual

200

Oil-Red-O

No

Name

Temp

Cond

DO

PH

density

Units

ppm

type

type

Units

degC

uS/cm

mg/L

-logio[H+]

g/mL

Type

Numeric

Categoric

Categoric

Obs

240

240

240

240

240

Low

Actual

0

none

4% Tween

80

Analysis

Polynomial

Polynomial

Polynomial

Polynomial

Polynomial

High

Actual

200

Oil-Red-O

No

Surfactant

Surfactant Minimum

15.9

0.968

3.18

4.32

0.982

Low

Coded

-1

Maximum

21.7

7610

10.48

7.96

1.02267

High

Coded

1

Mean

19.0454167

1138.94047

7.85408333

5.954125

1.00272192

Mean

100

Levels:

Levels:

Std. Dev.

1.1600556

2174.7257

1.53E+00

0.6675228

0.007443

Std.

Dev.

75

3

10

Max./Min.

Ratio

1.36478

7861.57

3.295597

1.842593

1.041415

Transform

None

Power

Power

None

None

Model

RLinear

RLJnear

Linear

RLinear

R2FI

RLinear = reduced linear model

Linear = linear model

R2FI = reduced 2 factor interaction

image:

Minimum

15.9

0.968

3.18

4.32

0.982

Low

Coded

-1

Maximum

21.7

7610

10.48

7.96

1.02267

High

Coded

1

Mean

19.0454167

1138.94047

7.85408333

5.954125

1.00272192

Mean

100

Levels:

Levels:

Std. Dev.

1.1600556

2174.7257

1.53E+00

0.6675228

0.007443

Std.

Dev.

75

3

10

Max./Min.

Ratio

1.36478

7861.57

3.295597

1.842593

1.041415

Transform

None

Power

Power

None

None

Model

RLinear

RLJnear

Linear

RLinear

R2FI

RLinear = reduced linear model

Linear = linear model

R2FI = reduced 2 factor interaction

image:

2.1 Experimental Set-up and Procedures

Prior to determining the mechanics of the experimental procedures, preliminary

instrument calibrations and test analyses were undertaken to address'issues pertinent to the

procedures and the required data quality. These preliminary (i.e., familiarity) experiments

determined:

- the operational calibration range for each instrument,

- the range of drift in standard

2.1 Experimental Set-up and Procedures

Prior to determining the mechanics of the experimental procedures, preliminary

instrument calibrations and test analyses were undertaken to address'issues pertinent to the

procedures and the required data quality. These preliminary (i.e., familiarity) experiments

determined:

- the operational calibration range for each instrument,

- the range of drift in standard  measurements

measurements over time and with fluctuating ambient

temperatures for each instrument,

— the optimal sample volume necessary to allow simultaneous

over time and with fluctuating ambient

temperatures for each instrument,

— the optimal sample volume necessary to allow simultaneous  measurements

measurements with

multiple instrument probes or electrodes,

- if the instrument probes or electrodes were negatively impacted by increasing levels of

with

multiple instrument probes or electrodes,

- if the instrument probes or electrodes were negatively impacted by increasing levels of

PCE

PCE in the

in the  solutions

solutions ,

- the general experimental characteristics of the surfactants to be used and if the

,

- the general experimental characteristics of the surfactants to be used and if the

measurements

measurements would be expected to fall within the calibration ranges of the

instruments,

— the sequence of response

would be expected to fall within the calibration ranges of the

instruments,

— the sequence of response  measurements

measurements to assure that quality data was collected, and

- decontamination of probes and electrodes (i.e., no "carry-over" effects).

The results of these validation and calibration experiments defined the following

experimental procedures and Quality Assurance/Quality Control (QA/QC) protocols, the

details of which can be found in Werkema (2006). Each of the 240 experimental runs

would be performed in a 400 mL beaker by accurately measuring 300 mL of the matrix

(e.g. DI water or

to assure that quality data was collected, and

- decontamination of probes and electrodes (i.e., no "carry-over" effects).

The results of these validation and calibration experiments defined the following

experimental procedures and Quality Assurance/Quality Control (QA/QC) protocols, the

details of which can be found in Werkema (2006). Each of the 240 experimental runs

would be performed in a 400 mL beaker by accurately measuring 300 mL of the matrix

(e.g. DI water or  surfactant

surfactant ) under a hood to vent volatiles.

) under a hood to vent volatiles.  PCE

PCE , dye (weighed out dry for

each beaker), and

, dye (weighed out dry for

each beaker), and  surfactant

surfactant concentrations were determined volumetrically and introduced

to the beaker. A magnetic stir bar was used for mixing. Five minutes after the introduction

of the specific experimental

concentrations were determined volumetrically and introduced

to the beaker. A magnetic stir bar was used for mixing. Five minutes after the introduction

of the specific experimental  treatment

treatment (i.e., independent variable) the responses (i.e.

dependent variables) were measured in the following order: temperature, conductivity, pH,

and DO. Density was then calculated through mass and volume

(i.e., independent variable) the responses (i.e.

dependent variables) were measured in the following order: temperature, conductivity, pH,

and DO. Density was then calculated through mass and volume  measurements

measurements . To verify

the concentration of

. To verify

the concentration of  PCE

PCE measured into the beakers, an aliquot of each sample matrix

containing

measured into the beakers, an aliquot of each sample matrix

containing  PCE

PCE were transferred to a labeled, pre-cleaned 40-mL glass vial with a Teflon-

lined, septum-sealed screw top (VOA vial) for analysis on the GC/MS. The volumes to be

sampled for each

were transferred to a labeled, pre-cleaned 40-mL glass vial with a Teflon-

lined, septum-sealed screw top (VOA vial) for analysis on the GC/MS. The volumes to be

sampled for each  PCE

PCE concentration and the blank are listed in Table 3 of the QAPP

(Werkema, 2006). These

concentration and the blank are listed in Table 3 of the QAPP

(Werkema, 2006). These  measurements

measurements were used to verify the concentration of

were used to verify the concentration of  PCE

PCE or

breakdown products in the samples undergoing the electrochemical testing. This analysis

served as a quality assurance check for the treatments.

2.2 Quality Assurance / Quality Control

2.2.1 Temperature

or

breakdown products in the samples undergoing the electrochemical testing. This analysis

served as a quality assurance check for the treatments.

2.2 Quality Assurance / Quality Control

2.2.1 Temperature  Measurements

Measurements Temperature resolution and accuracy for the two meters used are given as °C per

the instrument manufacturers. The Denver Instrument Electrochemistry Meter claims 0.1°

resolution, ± 0.3° accuracy (Denver Instrument Co., 1999) and the Accumet® Model AR 60

Meter: 0.1° resolution, ±0.1° accuracy (Fisher Scientific, 2003). The stand alone

temperature probe and pH electrode with Automatic Temperature Compensation (ATC),

image:

Temperature resolution and accuracy for the two meters used are given as °C per

the instrument manufacturers. The Denver Instrument Electrochemistry Meter claims 0.1°

resolution, ± 0.3° accuracy (Denver Instrument Co., 1999) and the Accumet® Model AR 60

Meter: 0.1° resolution, ±0.1° accuracy (Fisher Scientific, 2003). The stand alone

temperature probe and pH electrode with Automatic Temperature Compensation (ATC),

image:

conductivity ATC, and DO ATC all measure temperature, and if the readings were not

within ± 2°C, then all three temperature readings were recorded. The average of these

three was used in the data analysis. Otherwise, a single reading was recorded from the

conductivity ATC, and DO ATC all measure temperature, and if the readings were not

within ± 2°C, then all three temperature readings were recorded. The average of these

three was used in the data analysis. Otherwise, a single reading was recorded from the

measurements

measurements .

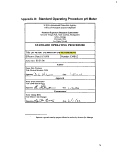

2.2.2 pH

.

2.2.2 pH  Measurements

Measurements

Measurements

Measurements for pH were made according to SW-846 Method 9040C, pH

Electrometric Measurement (USEPA, 2004), and the laboratory Standard Operating

Procedure (SOP), pH Meter: Calibration and

for pH were made according to SW-846 Method 9040C, pH

Electrometric Measurement (USEPA, 2004), and the laboratory Standard Operating

Procedure (SOP), pH Meter: Calibration and  Measurements

Measurements (see Appendix B). An

Accumet® glass-body, combination pH electrode with silver/silver chloride reference was

used for this procedure (Fisher Scientific, 2003). Temperature effects on the readings were

documented or mitigated by using a temperature probe with ATC in conjunction with the

(see Appendix B). An

Accumet® glass-body, combination pH electrode with silver/silver chloride reference was

used for this procedure (Fisher Scientific, 2003). Temperature effects on the readings were

documented or mitigated by using a temperature probe with ATC in conjunction with the

measurements

measurements and recording the temperature as each reading was being made. The probes

were used with a Denver Instrument 200 Series Electrochemistry Meter, which is capable

of three-to-five-point calibrations and simultaneous readings of multiple parameters

(Denver Instrument Co., 1999).

2.2.3 Conductivity

and recording the temperature as each reading was being made. The probes

were used with a Denver Instrument 200 Series Electrochemistry Meter, which is capable

of three-to-five-point calibrations and simultaneous readings of multiple parameters

(Denver Instrument Co., 1999).

2.2.3 Conductivity  Measurements

Measurements

Measurements

Measurements for conductivity followed SW-846 Method 9050A, Specific

Conductance (USEPA, 1996), and the laboratory SOP, Conductivity Meter: Calibration

and

for conductivity followed SW-846 Method 9050A, Specific

Conductance (USEPA, 1996), and the laboratory SOP, Conductivity Meter: Calibration

and  Measurements

Measurements (see Appendix C). A 4-cell, plastic-body probe and a 2-cell, glass-body

probe were used in this study. Both have a nominal cell constant of 1.0 cm"' and a

measurement range of 10.0- 2000 |iS/cm. The 2-cell probe was available for use with

samples containing high concentrations of

(see Appendix C). A 4-cell, plastic-body probe and a 2-cell, glass-body

probe were used in this study. Both have a nominal cell constant of 1.0 cm"' and a

measurement range of 10.0- 2000 |iS/cm. The 2-cell probe was available for use with

samples containing high concentrations of  PCE

PCE . The 4-cell probe has integrated ATC

capacity, and was used with the Denver Instrument Electrochemistry Meter which is

capable of a three-to-five-point calibration (Denver Instrument Co., 1999). The 2-cell

probe was used in conjunction with a stand-alone temperature probe, connected to an

Accumet® Research Model AR 60 pH/conductivity/DO meter, which has a single-point

calibration capability (Fisher Scientific, 2003). High concentrations of

. The 4-cell probe has integrated ATC

capacity, and was used with the Denver Instrument Electrochemistry Meter which is

capable of a three-to-five-point calibration (Denver Instrument Co., 1999). The 2-cell

probe was used in conjunction with a stand-alone temperature probe, connected to an

Accumet® Research Model AR 60 pH/conductivity/DO meter, which has a single-point

calibration capability (Fisher Scientific, 2003). High concentrations of  PCE

PCE were not used,

so the 4-cell ATC probe was used for all conductivity

were not used,

so the 4-cell ATC probe was used for all conductivity  measurements

measurements .

2.2.4 Dissolved Oxygen

.

2.2.4 Dissolved Oxygen  Measurements

Measurements Dissolved Oxygen'(DO)

Dissolved Oxygen'(DO)  measurements

measurements were conducted in accordance with Method

360.1, Dissolved Oxygen with Membrane Electrode (USEPA, 1975), and the laboratory

SOP Dissolved Oxygen Meter: Calibration and Measurement (see Appendix D). A Fisher

Scientific self-stirring Biological Oxygen Demand (BOD) probe (Fisher Scientific, 2003)

with electrolyte and a replaceable membrane were used for the analyses. The probe has a

self-contained ATC sensor and utilizes the Accumet® Research Model AR 60

pH/conductivity/DO meter (Fisher Scientific, 2003).

image:

were conducted in accordance with Method

360.1, Dissolved Oxygen with Membrane Electrode (USEPA, 1975), and the laboratory

SOP Dissolved Oxygen Meter: Calibration and Measurement (see Appendix D). A Fisher

Scientific self-stirring Biological Oxygen Demand (BOD) probe (Fisher Scientific, 2003)

with electrolyte and a replaceable membrane were used for the analyses. The probe has a

self-contained ATC sensor and utilizes the Accumet® Research Model AR 60

pH/conductivity/DO meter (Fisher Scientific, 2003).

image:

2.2.5 Density

2.2.5 Density  Measurements

Measurements Density was calculated from volume and mass

Density was calculated from volume and mass  measurements

measurements . The volume was

determined by inspection of a graduated cylinder at room temperature (@ 25°C). Mass was

measured using a Sartorius scale Model Number 3876 MP8-2, which was calibrated prior

to each use.

2.2.6 GC/MS Volatile Compound Analyses

All samples were stored at 0°C and analyzed within 14 days of preparation, if

possible. Samples were introduced by using Method 5035B, Purge-and-Trap, as per SW-

846 (USEPA, 1996; USEPA, 1996), and analyzed by GC/MS following the procedures in

EPA SW-846 Method 8260B, Volatile Organic Compounds by Gas Chromatography/Mass

Spectrometry (GC/MS): Capillary Technique (USEPA, 1996; USEPA, 2004). The

instrument was calibrated using internal standards for

. The volume was

determined by inspection of a graduated cylinder at room temperature (@ 25°C). Mass was

measured using a Sartorius scale Model Number 3876 MP8-2, which was calibrated prior

to each use.

2.2.6 GC/MS Volatile Compound Analyses

All samples were stored at 0°C and analyzed within 14 days of preparation, if

possible. Samples were introduced by using Method 5035B, Purge-and-Trap, as per SW-

846 (USEPA, 1996; USEPA, 1996), and analyzed by GC/MS following the procedures in

EPA SW-846 Method 8260B, Volatile Organic Compounds by Gas Chromatography/Mass

Spectrometry (GC/MS): Capillary Technique (USEPA, 1996; USEPA, 2004). The

instrument was calibrated using internal standards for  PCE

PCE and the applicable surrogate,

without regard to the other compounds listed in the method. Quality Assurance/Quality

Control (QA/QC) followed the guidelines in the Quality Assurance Project Plan (QAPP)

(Werkema, 2006).

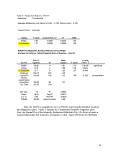

3.0 Results and Analysis

3.1 Quality Assurance / Quality Control

All data were collected using the SOPs specific to each instrument. The data and the SOPs

are included in the appendices. Appendix A summarizes the QA/QC protocols for the data

and references the QAPP for this project (Werkema, 2006). Appendix E includes the data

for the electrochemical measurement QA/QC. These analyses consist of: the individual

instrument calibrations per analytical date; and the initial calibrations, repeatability, and

potential instrument drift calculations. Furthermore, Appendix E indicates if any corrective

action was taken or if ongoing calibration check

and the applicable surrogate,

without regard to the other compounds listed in the method. Quality Assurance/Quality

Control (QA/QC) followed the guidelines in the Quality Assurance Project Plan (QAPP)

(Werkema, 2006).